7 Fulfillment

Reserving Inventory and Generating Pick Slips

Topics in this part:

- Reviewing Reservation Types describes the three types of reservations: Immediate, Batch, and Interactive.

- Reviewing Other Reservation Conditions discusses other reservation conditions, such as: Coordinate grouping, drop ship reservations, special handling reservations, and reserving inventory for sets and variable sets.

- Working with Interactive Reservation (MIRV) discusses creating, changing, deleting, and displaying order information using this reservation type.

- Preparing Orders for Pick Slip Generation provides an overview on preparing an order for pick slip generation.

- Performing Pick Slip Generation includes locating the pick slip generation function, printing pick slips, performing cubing, selecting pick locations, replenishing stock, and using cart/bin picking.

- Selecting Vendors for Drop Ship Processing (MDSP) includes creating, changing, deleting, and displaying vendors for drop ship processing.

- Displaying Pick Slip Generation Inquiry (DPSI) describes this management tool.

- Working with Pick Slip Messages (WPSM) describes creating, changing, deleting, and displaying pick slip messages.

- Processing Drop Ship Orders by Batch (MDSB) describes how to generate drop ship picks by batch for selected vendors.

- Printing the Carryover Report (PCOR) describes how to generate the Carryover reports.

- Generic Pick Out API describes how to generate the outbound

pick slip message for integration with another system.

For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1).

- Streamlined Pick Slip Generation (WSPS) describes a streamlined version of the pick slip generation option.

- Pick Print Eligibility (WPPE) determines whether the system will include picks for a specified order in the next pick slip generation run for the selected pick slip generation template.

- Unlock Pick Slip (MUPI) allows you to unlock a pick slip.

Reviewing Reservation Types

Purpose: The Reservation module reserves inventory from a specific warehouse or multiple warehouses for customer orders as they are entered and accepted through Order Entry.

The system continually evaluates new orders and backorders to ensure that stock is being reserved appropriately for all orders. There are two reservation types:

- Immediate = The system reserves stock when an order is placed, providing stock is available. In an immediate or real-time environment, the system reserves inventory on a first-come, first-served basis (FIFO) in the specified warehouse as each item is added to an order.

- Interactive = The system reserves stock through an interactive entry program. When using the Interactive Reservation function, no inventory is reserved until you use Working with Interactive Reservation (MIRV). This program allows you to disburse inventory manually to preferred customers or to customers who order in large wholesale volume.

Note:

In order for the system to reserve inventory for a particular item in a warehouse, the Reservation freeze field for that item warehouse must be unselected.In this topic:

- Reserve Warehouse Hierarchy

- Reviewing Immediate Reservation

- Reserving Stock with Immediate Reservation

- Reviewing Interactive Reservation

- Reserving Stock with Interactive Reservation

Reserve Warehouse Hierarchy

The system assigns a warehouse to an order or order line using the following hierarchy:

- A warehouse code for an individual order line: If you enter a warehouse code for an individual order line using the Add Line option, the system will use this warehouse to reserve the order line. This warehouse assignment will override all other reserve warehouse logic.

- A warehouse code entered on the order header: If you enter a warehouse code in the Warehouse field on the Work with Order screen, the system will use this warehouse to reserve all lines on the order. This warehouse assignment will override all other warehouse assignments except a warehouse code entered for an individual order line.

- Warehouse list: If you have not entered a warehouse code for an individual order line, or a warehouse code on the order header, the system will look for a warehouse list for the SCF of the order ship to address, if system control value Ship Complete from 1 Warehouse (B16) selected.

- The item’s primary warehouse: If no reserve warehouse can be assigned based on individual order lines, a warehouse code entered on the order header, or a warehouse list, the system will reserve the item in the warehouse defined for the item in the Item table. See Warehouse Lists and Single Order Lines.

Reviewing Immediate Reservation

Overview: In the Immediate Reservation environment, the system reserves inventory for an item when the order is placed. In addition, stock is reserved for eligible backorders as new merchandise is received into active inventory in the warehouse. This ensures that eligible backorders receive stock prior to new orders. Backorders are reviewed on a continual basis to ensure that eligible backorders receive stock prior to new orders and that orders are ready for printing as soon as possible.

The system prepares an order for pick slip generation when an order is created or changed; see Preparing Orders for Pick Slip Generation.

You must run Streamlined Pick Slip Generation (WSPS) to generate and print pick slips. See Performing Pick Slip Generation.

System control values which control Immediate Reservation:

| System Control Value | Results |

|---|---|

|

Immediate Reservation (A64) Selected/Unselected |

|

|

FIFO Flag (A03) Selected/Unselected |

|

|

Enter a valid Warehouse code that represents the primary shipping warehouse. This code will display on many screens throughout the system. NOTE If you are in a multiple warehouse environment, you may want to leave this field blank. |

|

|

Ship Complete from 1 Warehouse (B16) Selected/Unselected |

See Working with Warehouse Lists (WWHL) for an explanation of the system’s reserve warehouse logic. |

|

Split Line Over Multi Whse (B19) Selected/Unselected |

NOTE: When This system control value is not currently implemented. |

|

Enter the number of days after which an order (or order line) should be considered a future order and will not be reserved. |

Reserving Stock with Immediate Reservation

Determining stock availability: In the Immediate Reservation environment, the system reserves inventory on a first-come, first-served (FIFO) basis in the specified warehouse, as you add an item to an order.

The system is always attempting to reserve stock, based on your System Control table values and by using the Quantity Available calculation to determine if there is sufficient stock for new orders.

Quantity Available Calculation

On hand - Protected - Reserved - Reserve transfer - Backordered

= Quantity Available

Definitions:

On hand: the quantity of the item currently in the warehouse

Protected: the quantity of the item that can be reserved only through Interactive Reservation.

Reserved: the quantity of the item that is already set aside for other orders.

Reserve transfer: the quantity of the item set to be transferred to another warehouse

Backorder: the quantity of the item unavailable for existing orders that must be fulfilled through PO Receipts

Note:

Each time an item is reserved, the system reduces the Quantity available and updates the Quantity open by the Quantity ordered fields in the Item/Warehouse table. Availability is reduced, regardless of the reservation type.Reserving stock: In the Immediate Reservation environment, the system reserves stock, as follows:

- If the total order is available: The system increments the order detail line with the quantity reserved to fulfill the order. The program increments the Quantity open and Quantity reserved fields in the Item/Warehouse table.

- If a partial order is available: The system reserves what it can and backorders the rest. See Reserving Backorders.

- If no part of the order is available: See Reserving Backorders.

Note:

In a FIFO environment, an eligible order is any order taken for an item, open or held. In a Non-FIFO environment, only open orders are considered eligible for reservation.Reserving Backorders

Orders for which stock is unavailable at the time of order entry will not be eligible for immediate reservation. These orders will have stock reserved using the Evaluate Backorders Program. This is a batch program that can be initiated automatically by PO Receiving or Inventory Transactions. The system processes backorders as follows:

- When no part of the order is available: The system does not reserve the item in any warehouse and increments the Quantity backordered field in the Item/Warehouse table.

- When a partial order is available: The system reserves what it can and backorders the rest, and increments the Quantity reserved and the Quantity backordered fields in the Item/Warehouse table.

Note:

Any item/SKU which has been assigned a zone reservation code will be excluded from backorder reservation in the Evaluate Backorders Program. These items are normally reserved and shipped through the zone reservation process; however, zone reservation coded items which have been backordered through the standard order entry process can be reserved in Work with Interactive Reservation. See Shipping Zone Reservation Overview, for information on zone reservation. See Working with Interactive Reservation (MIRV), for more information on reserving interactively.Evaluating future orders: The arrival date is the date on which the customer wants to receive the order; this date controls whether the system reserves inventory immediately and whether to create pre-generated picks. The system uses the following calculation to determine future orders.

Future Orders Calculation:

If Arrival date - Reservation lead days is equal to or

greater than today's date, the order is a Future order.

The Evaluate Future Orders program runs each evening to evaluate all order detail lines marked as “future order.” The system re-runs the arrival date calculation and reserves the required inventory based on the order date, if the system-calculated date is less than or equal to today's date.

When the system determines that an order is a future order:

- Inventory is not reserved.

- Each detail line is marked as a future order.

Reviewing Interactive Reservation

Overview: This feature allows you to reserve stock for specific customers or orders via Working with Interactive Reservation (MIRV). No inventory is reserved until you run the Interactive Reservation Program to manually disperse inventory to preferred customers, or to customers who purchase large volumes of inventory.

You can designate specific customers for interactive reservation using a Customer Class code in which the Bypass reservation field is flagged, or by selecting the flag for individual customers; for these customers, orders is not reserved in order entry. You can designate specific items to bypass reservation in order entry by using a quantity limit in the Item/SKU table (i.e., items for which there is limited stock).

Note:

Use the Bypass reservation flag only if the Use OROB for Fulfillment Assignment (M31) system control value is unselected. This system control value uses the Bypass reservation flag to send orders to Order Orchestration for fulfillment assignment.System control values that control Interactive Reservations:

| System Control Value | Results |

|---|---|

|

Immediate Reservation (A64) Selected/Unselected |

|

|

FIFO Flag (A03) Selected/Unselected |

|

|

Default Warehouse (A04) |

Enter a valid Warehouse code that represents the default warehouse. This code will display on many screens throughout the system. NOTE: If you have multiple warehouses, you may want to leave this field blank. |

|

Ship Complete from 1 Warehouse (B16) Selected/Unselected |

See Working with Warehouse Lists (WWHL) for an explanation of the system’s reserve warehouse logic. |

|

Split Line Over Multi Whse (B19) Selected/Unselected |

NOTE: This system control value is not currently implemented. |

|

Reservation Lead Days (B27) |

Enter the number of days after which an order (or order line) should be considered a future order and will not be reserved. |

Reserving Stock with Interactive Reservation

Reservation conditions: In Working with Interactive Reservation (MIRV), the system reserves stock only if:

- The order is not a future order; the system-calculated date is less than or equal to today's date.

- The Reservation freeze field in the item/SKU warehouse record is not selected.

- Reservations can be performed against the warehouse in the Item/Warehouse record.

Note:

Each time an item is reserved, the system reduces the Quantity available and updates the Quantity reserved. Availability is reduced, regardless of the reservation type.Reserving stock: In the Immediate Reservation environment, the system reserves stock based on the values defined in the Quantity reserve limit field in the Item table. This quantity represents the maximum quantity that can be reserved for any one order through Immediate Reservation in order entry. If the quantity ordered by a customer exceeds this quantity, the system will not reserve any inventory for that order detail line. This order detail line must be flagged for reservation by the Interactive Reservation Program.

Displaying held orders: In Interactive Reservation, you can display held orders that have inventory reserved for them.

The list of held orders is displayed by hold code (e.g., all fraud orders are displayed first) and within hold code by date. You can release the inventory reservation on these orders; however, to cancel the order or take any other action, you must use the Order Maintenance function.

Reviewing Other Reservation Conditions

Purpose: The Reservation function reserves stock for customer orders; however, some orders may include items that require special handling, drop ships, or coordinate groups. Additionally, some orders have items that belong to sets or variable sets. These special conditions may cause the system to process reservations and generate picks differently than it would for regular items.

In this topic:

- Reserving Coordinate Group Items

- Reserving Drop Ship Items

- Reserving Special Handling Items

- Reserving Inventory for Finished Good Orders

- Reserving Inventory for Set Orders

- Reserving Inventory for Variable Set Orders

Reserving Coordinate Group Items

Overview: Coordinate grouping ensures that items on an order ship together. Items with the same coordinate group number will not allocate unless inventory is available for all of the items. Items are coordinate grouped in Order Entry and Order Maintenance.

If the Reservation program cannot reserve stock for all items linked by a common coordinate group, it will reserve stock for the available items and leave the other items on backorder. The remaining items will be reserved in the same manner as all other backorders.

Creating pre-generated picks: The system creates a pre-generated pick only if all lines that are coordinate grouped are eligible for pick slip preparation. The system may split the lines that are coordinate grouped across multiple picks. See Preparing Orders for Pick Slip Generation and Splitting an Order Across Multiple Picks.

Printing pick slips: No special information pertaining to coordinate grouping appears on the pick slip. See Performing Pick Slip Generation.

Important:

The same ship via must be assigned to items that belong to the same coordinate group.Reserving Drop Ship Items

Overview: A drop ship item is an item that you do not stock in inventory. When a customer places an order for a drop ship item, you order the item from your supplier (vendor). The vendor ships the item directly to your customer.

Reserving stock: To use the Drop Ship Reservation feature, you must indicate in the Vendor table whether you want to send drop ship picks, POs, and/or EDI transmissions, or process drop ship orders for this vendor using the Order Orchestration Drop Ship Integration. You can also ship items that are typically drop ship items from your own warehouse. For example, you may have returns that can be used to fulfill new orders; these items could be shipped from your warehouse rather than the vendor's warehouse.

When you take an order for a drop ship item, the system attempts to reserve stock from your warehouse, rather than from the vendor, as follows:

- If the entire quantity is available in the warehouse, it is reserved.

- If the entire quantity is not available in the warehouse, the system requires the order be sent from the vendor.

Printing drop ship pick slips: Drop ship items produce drop ship pick slips or drop ship purchase orders. If a drop ship item cannot be allocated from inventory, which is usually the case, the system produces a drop ship pick slip or purchase order.

The system performs the following procedures during drop ship processing:

- An item is flagged as “Drop Ship” in the Item table.

- When you add the item to an order, it displays on neither reserved nor backordered. The “Drop Ship” flag appears on the order line detail.

- When you generate pick slips or purchase orders, the system checks the Item/SKU table to determine the primary vendor assigned to the item/SKU ordered.

- The system then checks the Vendor table to determine whether this vendor takes drop ship purchase orders, drop ship pick slips, or processes drop ship orders using the interface with Order Orchestration’s Drop Ship Manager. If the vendor takes drop ship pick slips, the system prints a separate pick slip.

Reserving Special Handling Items

Overview: Items that can be personalized or finished are considered special handling (S/H) items. Personalization might include monogramming, engraving, hemming, etc.

Reserving S/H items: The system reserves inventory for these items in the same way as for any other item. A separate processing step is not required to reserve stock for these orders. Stock is reserved immediately or by the Evaluate All Backorders Program. See Reviewing Reservation Types.

As inventory is reserved for these orders, the reservation program increments the S/H Reserve field in the Item/Warehouse table.

Pick slip preparation: The Split Special Handling Picks (L44) controls whether the system creates a separate pre-generated pick for the order lines on an order that contain a special handling code. This system control value also controls whether the system creates a separate pick slip PDF document for picks that contain items that require special handling.

Printing pick slips: The Special Handling field on the Streamlined Pick Slip Generation Screen allows you to select pre-generated picks for pick slip generation based on the presence of a special handling code for an item. Special handling instructions entered during Order Entry will print on the pick slip if the pick slip printing program you are using permits it. This is true whether the line prints on an individual pick slip or is on a pick slip with other items.

Reserving Inventory for Finished Good Orders

Overview: Finished good orders are orders that require assembly prior to picking and packing. A finished good, defined as Finished Good in the Kit type field in the Item table, is comprised of one or more component items that you may also sell individually.

Reserving stock: Finished goods are reserved at the finished good level, not at the component level.

Orders where the inventory is not reserved immediately will have stock reserved using the Evaluate All Backorders Program. See Reviewing Reservation Types.

Creating pre-generated picks: Typically, the system looks at the lead days for the shipper and your internal lead time to determine when to create a pre-generated pick.

Printing pick slips: The pick slip lists only the finished good; component information does not appear.

See Entering Finished Goods Information (WFGD) for more information on working with finished goods.

Reserving Inventory for Set Orders

Overview: A set item, identified by a Set in the Kit type field in the Item table, is composed of two or more items that you sell together as a unit. The items that make up a set are often referred to as components. You can also sell these components individually.

Reserving stock: Sets are reserved at the component level only. Orders where the inventory is not reserved immediately will have stock reserved using the Evaluate All Backorders Program. See Reviewing Reservation Types.

Soldouts:

- Component item(s): If any of the component items on a set are sold out based on the assigned soldout control code and the current inventory situation, the main set item and each of the component items are added to the order in a soldout status (S). For example, if the set includes five items, and one of the items is assigned a soldout control code indicating to sell the item out immediately, the main set item and all of the component items will be added to the order in a soldout status.

- Main set item: Similarly, if the main set item itself is assigned any soldout control code, the main set item and each of the component items are added to the order in a soldout status (S).

See Working with Soldout Controls (WSLD) for a discussion on how soldout controls indicate when an item is sold out.

Pick slip preparation: To create a pre-generated pick for a set:

- If the set and component items are coordinate grouped, all of the component items must be reserved and in an open status.

- If the set and component items are not coordinate grouped, at least one of the component items must be reserved and in an open status.

See Selecting Order Lines for Pick Slip Preparation.

Printing pick slips: The pick slip shows the components of the set, but not the price of each component. The price of the set displays on the pick slip next to the set item only.

For more information: See Entering Set Information (WSET) for more information on working with sets.

Reserving Inventory for Variable Set Orders

Overview: Variable sets, defined as Variable Set in the Kit type field in the Item table, are items that allow customers to choose from a list of component items to make up the set they want to purchase.

Reserving stock: Variable sets are reserved at the component level. Orders where inventory is not reserved immediately will have stock reserved using the Evaluate All Backorders Program. See Reviewing Reservation Types.

Printing pick slips: The pick slip lists an order detail line for each component item and does not refer to the variable set at all. Prices are shown for each component.

See Entering Variable Set Information (WVST) for more information on working with variable sets.

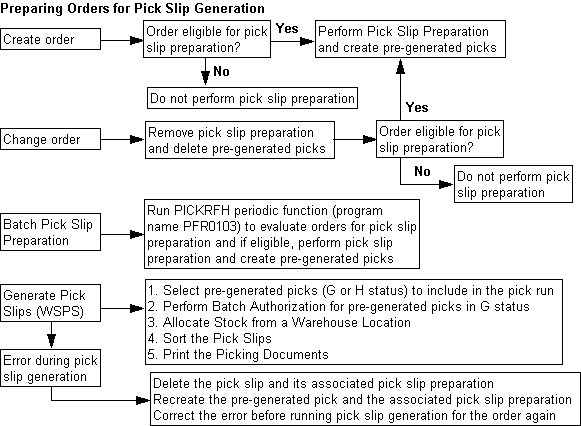

Preparing Orders for Pick Slip Generation

Pick slip preparation prepares an order for fulfillment when you create or change an order, such as creating pre-generated picks in the Pick Control Header and Pick Control Detail tables and defining whether the pre-generated picks require authorization. Preparing the order for pick slip generation in advance reduces the time it takes to run Streamlined Pick Slip Generation (WSPS) to fulfill and print the picking documents.

Pre-generated picks are picks created prior to running pick slip generation for an order. The status of a pre-generated pick is either G Generated No Authorization, indicating the pick requires authorization during pick slip generation, or H Generated Has Authorization, indicating the pick can bypass authorization during pick slip generation. Pick slip generation selects pre-generated picks to fulfill and print based on the pick slip selection criteria specified.

Pick slip preparation process:

Standard pick slip generation: You cannot use standard pick slip generation (WPSG) for orders that are eligible for pick slip preparation; you must use Streamlined Pick Slip Generation (WSPS) to complete the pick slip generation process.

In this topic:

- Pick Slip Preparation Setup Requirements

- Selecting Order Lines for Pick Slip Preparation

- When is Pick Slip Preparation Performed?

- Batch Pick Slip Preparation

- Applying Pick Slip Preparation to an Order

- Splitting an Order Across Multiple Picks

- Creating Pre-Generated Picks

- Removing Pick Slip Preparation from an Order

For more information: See:

- Performing Pick Slip Generation for an overview and processing details.

- Streamlined Pick Slip Generation (WSPS) to review the options you can use to select picks for pick slip generation.

Pick Slip Preparation Setup Requirements

For more information: See Pick Slip Generation Setup Requirements for more information on the setup required to run pick slip generation.

Pick Slip Generation Templates

Use the Streamlined Pick Slip Generation Screen to create pick slip generation templates to define the selection criteria the system uses to select pre-generated picks for fulfillment. Review the pick slip generation templates that you may have used in Standard Pick Slip Generation (WPSG) to determine the pick slip generation templates to create in Streamlined Pick Slip Generation.

System Control Values

| System Control Value | Description |

|---|---|

|

Enter the number of days after which an order (or order line) should be considered a future order and should not be reserved. The FUTURE periodic function (FLR0246) uses this number of days to determine when an order line’s arrival date makes it eligible to reserve as a future order. |

|

|

Enter the number of days it takes your company, on average, to pick, pack, and ship an order. This is your internal lead time. This number determines when to create a pre-generated pick; see Selecting Order Lines for Pick Slip Preparation. |

|

|

Select this field to have pick slip preparation create a separate pre-generated pick for all items on an order that contain a special handling code. When you generate pick slips for the order, the system creates a separate PDF document for picks that contain items with special handling. Deselect this field to have pick slip preparation include items on the order that contain a special handling code on the same pre-generated pick as the other shippable items on the order (assuming another reason does not cause the system to split the order across multiple picks; see Splitting an Order Across Multiple Picks). When you generate pick slips for the order, the system does not create a separate PDF document for special handling items. See this system control value for examples. |

|

|

Select this field to have pick slip preparation create a separate pre-generated pick for each item on a ship-for-pickup order. When you generate pick slips for the order, the system submits each order line to Order Orchestration as a separate order. Deselect this field to have pick slip preparation include all reserved items within the warehouse on the same pre-generated pick. When you generate pick slips for the order, the system submits all items on the pick slip together, even if it creates a multi-line order. See Ship-for-Pickup Orders for background. |

Selecting Order Lines for Pick Slip Preparation

In order for the system to perform pick slip preparation and create pre-generated picks, an order must meet the following requirements.

- The Order Header must be in an open status and not locked by a user.

- A line on the order must be reserved and in an open status.

- For each reserved, open order line:

- The Arrival date cannot be a future arrival date. The system uses the arrival date defined for the order line or the order ship to if not defined at the line level; see Arrival Date Calculation.

- The Cancel date cannot fall within the time it takes to process and fulfill the pick slip. The system uses the cancel date defined for the order line or the order ship to if not defined at the line level; see Cancel Date Calculation.

- The Quantity remaining must be less than or equal to the Quantity reserved in the Reserved Order Line table.

- The Quantity remaining in the Reserved Order Line table must be less than or equal to the Quantity reserved - Quantity Printed in the Order Detail table.

- The Quantity printed in the Reserved Order Line table must be less than or equal to the Quantity reserved in the Order Detail table.

Also:

Ship complete orders: If the order is flagged as ship complete, all of the lines on the order must be reserved and in an open status.

Sets: If the order contains a set and the set and component items are coordinate grouped, all of the component items must be reserved and in an open status. If the set and component items are not coordinate grouped, at least one of the component items must be reserved and in an open status.

Coordinate-grouped items: Pick slip preparation is not applied to order lines that are assigned the same coordinate group number until all of the coordinate grouped lines are eligible for pick slip preparation.

Non-inventory items: If the only items on the order are non-inventory, the items do not need to be reserved, but must be in an open status in order to be eligible for pick slip preparation. The system creates a pre-generated pick for the non-inventory item, even if all other items on the order are not eligible for pick slip preparation; however, the system will not create a pre-generated pick for a non-inventory item if all other items on the order are backordered; when one or more backordered items are available, the system creates a pre-generated pick for the non-inventory item as well as for the available item(s).

Drop ship items: The system does not include drop ship items on a pre-generated pick.

Multiple recipients: If the order contains multiple recipients, the system evaluates each order ship to individually to determine if it qualifies for pick slip preparation.

Ship-for-pickup orders: If the Create Separate Picks for Ship for Pickup Orders (L89) system control value is selected, the system prepares a separate pick for each reserved order line.

Arrival Date Calculation

The system checks the arrival date for each line on an order to determine when to create a pre-generated pick.

Arrival Date from Order Line (or Order Ship To) - (Pick

Processing Days (B37) + Ship Via Lead Days in WSHV) < or = Today's

Date

The system creates a pre-generated pick for the order line if this system-calculated date is less than or equal to today's date; otherwise, the system does not create a pre-generated pick for the order line until the date is within the allotted time frame.

Note:

To retrieve the correct ship via lead days in Working with SCF/Ship Via Values (WSHV), the system uses the ship via on the order line (or order ship it not defined at the line level) and the SCF (first 3 digits of the postal code) and country code defined for the order ship to delivery address.Cancel Date Calculation

The system checks the cancel date for each line on the order to determine whether to create a pre-generated pick.

Cancel Date > Today’s Date + Pick Processing Days (B37)

+ Ship Via Lead Days in WSHV

The system creates a pre-generated pick for the order line if the cancel date is greater than this system-calculated date; otherwise, the system does not create a pre-generated pick for the order line.

Fields used in the arrival date and cancel date calculations:

Arrival date is the date when the customer wants to receive the order. This date controls whether the system reserves inventory and prints pre-generated picks immediately.

You can define the arrival date for an order line on the Work with Order Line Screen (Changing/Adding an Item) and you can define an arrival date for an order ship to on the Work with Order Screen. See Reviewing Reservation Types.

Cancel date is the date when the customer wants to cancel an order if it has not been shipped.

You can define a cancel date for an order line on the Work with Order Line Screen (Changing/Adding an Item) and you can define a cancel date for an order ship to on the Work with Order Screen.

Pick processing days are the number of days it takes your company, on average, to pick, pack, and ship an order. This is your internal lead time. The system uses this number to determine when to generate a pick slip.

You use the Pick Processing Days (B37) system control value to define your pick processing days.

Ship via lead days, as defined in the Working with SCF/Ship Via Values (WSHV) menu option, represents the number of days it takes a shipper to deliver the order to its destination. The SCF represents the first 3 positions of the destination postal code. To retrieve the correct ship via lead days, the system uses the ship via on the order line (or order ship it not defined at the line level) and the SCF (first 3 digits of the postal code) and country code defined for the order ship to delivery address.

When is Pick Slip Preparation Performed?

The system performs pick slip preparation when:

- An order is created; see Pick Slip Preparation when an Order is Created.

- A user or the system updates an order; see Pick Slip Preparation when an Order is Maintained.

- Pick slip generation (WSPS) cannot generate a pick slip; see Pick Slip Preparation when Pick Slips are not Generated (WSPS).

Pick Slip Preparation when an Order is Created

The system performs pick slip preparation when an order is created; see Applying Pick Slip Preparation to an Order for the updates that are performed.

| Pick Slip Preparation... | applied to an order when: |

|---|---|

|

The system performs the final order accept. If the order contains multiple recipients, the system does not perform pick slip preparation until you accept the last order ship to on the order. |

|

|

Generic Order Interface (Order API) For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1). |

Order Administration receives the order through the Generic Order Interface (Order API) and it is not placed in an error status. Pick slip preparation occurs after the system generates the Order Response. |

|

You select to Edit/Accept the order batch. The system performs pick slip preparation only for orders that are accepted in the order batch. |

|

|

Order Administration generates a membership order. |

Pick Slip Preparation when an Order is Maintained

The system performs pick slip preparation when a user or the system updates an order. In this situation, the system performs the following updates.

- The system REMOVES any pick slip preparation from the order; see Removing Pick Slip Preparation from an Order for the updates that are performed.

- Once the changes to the order have been made, the system EVALUATES the order to determine if it is eligible for pick slip preparation.

- If the order is eligible for pick slip preparation after the changes to the order have been made, the system RE-APPLIES pick slip preparation to the order; see Applying Pick Slip Preparation to an Order for the updates that are performed.

| Pick Slip Preparation... | removed and reapplied to an order when: |

|---|---|

|

Removed when you select the order for maintenance, across all order ship tos. Reapplied when you accept or reject the order maintenance changes, across all order ship tos. |

|

|

You release an order from hold and its status changes to Open. See Manage Held Orders in Modern View online help. |

|

|

You release an order from hold and its status changes to Open. |

|

|

You select Release to release an order line from hold or select Batch Release to release multiple order lines from hold. |

|

|

Evaluate Future Orders periodic function (program name FLR0246) |

An order is reserved and updated to an open status. |

|

Stock is reserved against an order. |

|

|

Evaluate Backorder Reasons without Backorder Warehouse periodic function (program name PFR0024) |

An item on backorder is reserved. |

|

Reserve Backorders periodic function (program name FLR0804) |

An item on backorder is reserved. |

|

|

|

Working with Return Authorizations (WRTA) and Receiving Returns (WRAR) |

Removed when you select an order for return authorization. Reapplied when you accept or reject the return authorization. If you add an exchange item, the system performs pick slip preparation for the exchange item when you receive the return authorization. |

|

Removed when you:

Reapplied when you exit the screen. |

|

|

You substitute an item that is on backorder with an item that is in stock. |

|

|

Inventory Transaction Upload XML Message (inCreateInvXaction) For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1). |

The system unreserves an order to perform a negative adjustment. |

|

Release Order on Time Hold periodic function (program name CSR0557) |

An order is released from hold. |

|

You cancel an item that is on backorder and the order is flagged as ship complete or the item being cancelled is the item that prevented a pre-generated pick from being created for the order. |

|

|

You cancel orders whose credit cards have been declined by the authorization service. NOTE: Because the order is cancelled, the system removes pick slip preparation from the order and does not reapply it. |

|

|

An order is unreserved. |

|

|

You refund a stored value card item, causing the system to add a new stored value card item to the order and create a pre-generated pick for the new card. |

|

|

You perform the reset. NOTE: To reduce the amount of time it takes to run this process, you should use Streamlined Pick Slip Generation (WSPS) to generate pick slips for as many orders as possible. |

|

|

You unlock an order. |

|

|

You void a pick slip. NOTE:

|

|

|

Generic Pick In API (Shipments, Voids, and Backorders) For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1). |

The transaction_type for a CWPickIn XML Message is B (full or partial backorder) or V (void). For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1). NOTE: The Generic Pick In API is available only for pick slips that have been fulfilled and printed through Streamlined Pick Slip Generation (WSPS); you cannot use the Generic Pick In API for pre-generated picks (picks in a G Generated No Authorization or H Generated Has Authorization status). |

|

A NO New Order tickler is created. NOTE: If the order is placed on hold, the system does not reapply pick slip preparation to the order. |

|

|

A VP Voided Pick Tickets tickler is created. NOTE: If the order is placed on hold, the system does not reapply pick slip preparation to the order. |

Pick Slip Preparation when Pick Slips are not Generated (WSPS)

If the system cannot generate a pick slip during pick slip generation, the system determines the updates that need to be performed for pick slip preparation.

| Pick Slip Not Generated Because: | Pick Slip Preparation Updates: |

|---|---|

|

The system:

NOTE: If the authorization remains in an S Sent status, the system updates the status of the pick to W Waiting for Authorization and does not delete it. |

|

|

Allocating Stock Error |

If a stock allocation error occurs and the Withhold Picks due to Item Allocation Error (F04) system control value is selected, the system:

If a stock allocation error occurs and the Withhold Picks due to Item Allocation Error (F04) system control value is unselected, the system:

NOTE: If the item that has the item stock allocation error is part of a set or is part of a coordinate group, the system holds the other items that are part of the set or coordinate group. See the Withhold Picks due to Item Allocation Error (F04) system control value for examples. |

|

Stored value card number not assigned during pick slip generation |

If the system cannot assign a card number to a virtual stored value card or a card using the Oracle Retail Customer Engagement Stored Value Card integration, the system:

|

|

Order Orchestration indicates the retail pickup or delivery order has been canceled |

If Order Administration sends pick slip information to Order Orchestration and Order Orchestration indicates the order or line has been canceled, the system:

See Retail Pickup (including Ship-for-Pickup) or Delivery Orders and the Use OROB Status Inquiry List Web Service (M05) system control value. |

|

Order Orchestration indicates the retail pickup or delivery order is under review |

If Order Administration sends pick slip information to Order Orchestration and Order Orchestration indicates the order is under review, the system:

See Retail Pickup (including Ship-for-Pickup) or Delivery Orders and the Use OROB Status Inquiry List Web Service (M05) system control value. |

|

Error During Ship-for-pickup Order Processing |

If Order Administration sends pick slip information to Order Orchestration and Order Orchestration returns an error, the system:

|

Batch Pick Slip Preparation

The PICKRFH Pick Gen Refresh periodic function (program name PFR0103) allows you to submit a process that evaluates orders for pick slip preparation, and if eligible:

- Removes any pick slip preparation that may have already occurred for the order; see Removing Pick Slip Preparation from an Order for the updates that are performed.

- Applies pick slip preparation to the order; see Applying Pick Slip Preparation to an Order for the updates that are performed.

Use this periodic function to:

- Initially prepare existing orders for pick slip generation; see Converting Orders to Pick Slip Preparation.

- Perform pick slip preparation for orders that initially were not eligible for pick slip preparation (for example, the order had a future arrival date).

See How to Schedule a Job for instructions on assigning this periodic function to a periodic process and to schedule when the process runs.

Note:

Oracle recommends you run this periodic function on a daily basis.Logging: For each eligible order, the system writes a message to the Trace Log if its Logging Level is set to ERROR or higher.

Converting Orders to Pick Slip Preparation

Use the following steps to apply pick slip preparation to existing open and reserved orders.

Before running the PICKRFH Pick Gen Refresh periodic function and to minimize the amount of time it takes to convert orders to pick slip preparation, you should:

- Make sure you have a current backup of the Order Administration database.

- Use Streamlined Pick Slip Generation (WSPS) to generate pick slips for as many orders as possible to reduce the number of orders that require pick slip preparation.

To estimate the time it will take you to run the conversion process, to perform pick slip preparation for 11,000 orders takes roughly 68 minutes; however, based on your system, your time may vary.

To run the conversion process:

- Log all users off Order Administration and stop any batch jobs, such as Background Asyncs (MBJC) and any Integration Layer Jobs (IJCT). This ensures there are no locks on the Order and Pick tables, no new orders are created during the conversion process, and reduces the conversion time.

- Log in to Order Administration and verify you are in the company you wish to convert.

- In Executing Periodic Processes (EPRO), select the CVTIAPICK periodic process and select OK.

- At the First Execute Periodic Process Screen (Setting Parameters), enter the company you wish to convert and select OK.

- On the Second Execute Periodic Process Screen (Selecting Functions), select Execute. The system submits the CVTIAPICK job.

- Once the CVTIAPICK job completes, open the Trace Log and verify

the system wrote a message indicating the conversion completed. The

message should be similar to the following:

PickGen Refresh completed. It generated picks for approximately 9999 orders.

Once the conversion process completes, you can allow users back in the system.

Applying Pick Slip Preparation to an Order

For orders that qualify for pick slip preparation, the system performs the following updates.

- Creates Pre-Generated Picks

- Updates Reserved Order Lines for the Order

- Updates Authorizations for the Order

For more information: See Selecting Order Lines for Pick Slip Preparation and When is Pick Slip Preparation Performed? for more information on determining when an order line is eligible for pick slip preparation, and when the system performs pick slip preparation.

Creates Pre-Generated Picks

When creating pre-generated picks for an order, the system performs the following updates.

Splits an order across multiple picks: The system may split an order into multiple pre-generated picks for several reasons; see Splitting an Order Across Multiple Picks.

Flags a pick as the first pick: If a pick doesn’t already exist for the order that is flagged as the first pick, the system flags the pre-generated pick as the first pick. If multiple pre-generated picks are created for the order, the system flags one of the picks as the first pick. If a pick contains only bill immediately items (such as virtual stored value card items, membership items, and subscription items), the system flags this pick as the first pick.

- If the Prorate Freight Charges (D39) system control value is unselected, the system charges all freight charges on an order with the first shipment; in this situation, all freight charges are added to the pick the system flags as the first pick.

- If the Prorate Freight Charges (D39) system control value is selected, the system charges a proportional amount of freight for partial shipments on an order. However, if the Prorate Freight Charges (D39) system control value is selected and all of the items on the order are exempt from freight, the system applies any item and weight charges defined for the ship via to the pick the system flags as the first pick.

Note:

If the pick flagged as the first pick is NOT selected for the first pick slip generation run for the order, the system:- Updates the First pick field in the Pick Control Header table for the pick that is included in the pick slip generation run to Y and looks at the setting of the Prorate Freight Charges (D39) system control value to determine how to apply freight charges.

- Updates the First pick field in the Pick Control Header table for the pick that was originally flagged as the first pick to N.

Recalculates tax: The system recalculates the tax for each pick created.

Creates a record in the Pick Control Header table: The system creates a record in the Pick Control Header table for each pick created for the order; see Creating Pre-Generated Picks for information on the fields that are updated. If the Split Special Handling Picks (L44) system control value is selected, the system creates a separate Pick Control Header record for all items on the order that contain a special handling code.

Creates a record in the Pick Control Detail table: The system creates a record in the Pick Control Detail table for each item on the order that qualifies for pick slip preparation; see Creating Pre-Generated Picks for information on the fields that are updated.

Creates a record in the Pick Stored Value Card table: The system creates a record in the Pick Store Value Card table for each physical stored value card item included on the pre-generated pick.

Viewing pre-generated picks: You can review pre-generated picks on the Display Pick Tickets for Order Screen in Order Inquiry. The status of the pick will be either G Generated No Authorization or H Generated Has Authorization; see Pick status for more information on how the system determines the status of the pre-generated pick.

Note:

Picks in a G or H status will not display on the Display Pick Tickets for Order Screen in Order Maintenance because the system removes these picks when you advance to Order Maintenance and does not recreate them until you accept or reject out of Order Maintenance.Updates Reserved Order Lines for the Order

The system updates the Reserved Order Line table for the order:

- Increments the Qty printed by the quantity on the Pick Control Detail.

- Decrements the Qty remaining by the quantity on the Pick Control Detail.

You can review the reserved order lines on an order on the Display Reserved Order Lines Screen in Order Inquiry.

Note:

The system does not update the Qty printed in the Order Detail table during pick slip preparation; this update occurs during pick slip generation. You can review the quantity printed for an order detail line on the Order Inquiry Detail Screen.Updates Authorizations for the Order

If the credit card payment on the order has been authorized, the system performs the following updates.

Determines if the authorization has expired: If the authorization for the credit card payment has expired, the system:

- Updates the Status of the Authorization History record to E Expired.

- Reduces the Amount authorized on the Order Payment Method by the expired authorization amount.

- Reduces the Void Auths record by the expired authorization amount.

You can review authorizations in an E Expired status on the Display Authorization History Screen in Order Inquiry.

If the authorization for the credit card payment has NOT expired, the system performs the updates below.

Creates an Authorization History record if it does not yet exist: The record contains:

- A Status of A Authorized if the credit card was authorized using online authorization, or G Generated if the credit card contains a manual authorization. Once a pick associated with a manual authorization is printed, the system updates the status to A Authorized.

- The authorization date defined for the payment (or the current date if an authorization date was not defined).

- The authorization number defined for the payment.

- The authorization amount defined for the payment (or the Total Order Amount for the Pick Control Header if an authorization amount was not defined).

You can review authorizations in an A Authorized and G Generated status on the Display Authorization History Screen in Order Inquiry.

Creates an Authorization History Pick record: The system creates an Auth History Pick record for each pre-generated pick created for the order.

Creates an Order Transaction History record: A message similar to the following is created if a manual authorization

exists on the order, where TST3442 is the authorization

number, 99.99 is the authorization amount, and OEPICKAUTH is the user:

AUTH MANUAL AUTH# DETECTED - TST3442 99.99 OEPICKAUTH

You can review order history on the Display Order History Screen.

Updates authorizations for the Order Payment Method:

If the Pick status for the Pick Control Header record is H Generated Has Authorization, the system:

- Removes the Authorization date, Authorization number, and Manual authorization amount from the Order Payment Method.

- Updates the Amount authorized with the authorization amount.

If the Pick status for the Pick Control Header record is G Generated No Authorization, the system:

- Retains the Authorization date, Authorization number, and Manual authorization amount for the Order Payment Method.

- Does not update the Amount authorized.

- Creates a record in the Void Auths table for the amount authorized.

You can review this information on the Display Order Pay Type Screen (1 of 2).

Creates a record in the Void Auths table: The system creates a record in the Void Auths table when:

- The credit card payment on the order has been authorized, but the Pick status for the Pick Control Header record is G Generated No Authorization.

- The Manual authorization amount for the Order Payment Method is greater than the Total Order Amount for the Pick Control Header; in this situation, the system takes the difference and creates a Void Auths record for the amount. Example: If the Manual authorization amount is 50.00 and the Total Order Amount is 30.00, the system creates a Void Auths record for 20.00.

- The credit card payment on the order has been authorized, but the order is not eligible for pick slip preparation (for example, the order is placed on hold).

Splitting an Order Across Multiple Picks

The system splits an order into several pre-generated picks for any of the following reasons.

Important:

If you change an item in Work with Item/SKUs (MITM) or change a ship via in Working with Ship Via Codes (WVIA) after a pre-generated pick has been created, the system does not recreate the picks based on the updated information. You must change the order to trigger the system to remove and reapply pick slip preparation to the order.| Reason to Split an Order | Description |

|---|---|

|

Different warehouse for item |

An order line on the order is in a different warehouse than other order lines on the order, or a single order line on the order is reserved from multiple warehouses. Example: If item A123 is reserved in warehouse 1 and items B123 and C123 are reserved in warehouse 2, the system creates a Pick Control record for item A123 and a separate Pick Control record for items B123 and C123. NOTE: The system also creates a separate pick slip PDF document for picks based on warehouse; see Sorting Pick Slips into Separate PDF Documents. |

|

Different ship via for item |

An order line on the order is assigned to a different ship via than other order lines on the order. Example: If item A123 is assigned ship via 1 and items B123 and C123 are assigned ship via 2, the system creates a Pick Control record for item A123 and a separate Pick Control record for items B123 and C123. NOTE: The system also creates a separate pick slip PDF document for picks based on warehouse; see Sorting Pick Slips into Separate PDF Documents. |

|

Special handling for item |

An item on the order requires special handling or personalization. The system splits an order by special handling only if the Split Special Handling Picks (L44) system control value is selected. This system control value also works in conjunction with the setting of the Special Handling field on the Streamlined Pick Slip Generation Screen. Example: See the Split Special Handling Picks (L44) system control value for examples. NOTE: If the Split Special Handling Picks (L44) system control value is selected, the system also creates a separate pick slip PDF document for picks based on special handling; see Sorting Pick Slips into Separate PDF Documents. |

|

Physical stored value card |

An item on the order is flagged as a physical stored value card. The system creates a separate Pick Control record for each order line that has a physical stored value card. Also, if the physical stored value card item is set up as a ship alone item, the system creates a separate Pick Control record for each unit of a stored value card item on an order line. You can flag an item as a physical stored value card at the Create Item Screen or Change Item screen. Example: An order has the following order lines. The stored value cards are NOT flagged to ship alone.

Results: The system creates the following pre-generated picks:

See Stored Value Card Purchase and Activation for more information on generating pick slips for stored value card items. |

|

Ship alone item |

An item on the order is flagged to ship alone. Example: An order has the following order lines:

Results: The system creates the following pre-generated picks:

|

|

Hazardous item |

An item on the order is flagged as hazardous. Example: An order has the following order lines:

Results: The system creates the following pre-generated picks:

|

|

Different location class for item |

An item on the order has a different location class than other items on the order. NOTE: The system uses the location class defined at the item level. Example: An order has the following order lines:

Results: The system creates the following pre-generated picks:

|

|

Ship-for-pickup order |

The order is a ship-for-pickup order and the Create Separate Picks for Ship for Pickup Orders (L89) system control value is selected. Example: An order has the following order lines:

Results: The system creates the following pre-generated picks:

|

Creating Pre-Generated Picks

Pick Slip Preparation creates pre-generated picks in the Pick Control Header and Pick Control Detail tables when an order is created or changed. You can review pre-generated picks on the Display Pick Tickets for Order Screen.

- Pick Control Header Updates for Pre-Generated Picks

- Pick Control Detail Updates for Pre-Generated Picks

Restrictions: The following options are not available until after you use Streamlined Pick Slip Generation (WSPS) to fulfill and print a pick slip:

- You cannot confirm and bill shipments for a pre-generated pick using the Manually Confirming Shipments (MCON) menu option.

- You cannot assign a number to a physical stored value card using the Working with Physical Stored Value Card Assignment (WPSA) menu option.

- You cannot use the Generic Pick In API (Shipments, Voids, and

Backorders) for a pre-generated pick.

For more information see the Order Administration Web Services Guide on My Oracle Support (ID 2953017.1).

- Pre-generated picks do not display in the Displaying Pick Slip Generation Inquiry (DPSI) menu option.

- The Printed field in the Reviewing Pending Orders (DOSS) menu option does not include pre-generated picks.

- Pre-generated picks are not included in the Reviewing Operations Control Summary (FLSH) menu option.

- Pre-generated picks are not included in the Ship Via/Item Inquiry (SVII) menu option.

- Pre-generated picks are not included on the Operations Control Report (POCT).

- Pre-generated picks are not included on the Carryover Report (PCOR).

Pick Control Header Updates for Pre-Generated Picks

Pick Slip Preparation updates the following fields in the Pick Control Header table for pre-generated picks. The remaining fields are not updated until you run pick slip generation for the order.

Subscription items: The system creates a separate pre-generated pick for a subscription item (the Subscription and Non-inventory fields for the item are selected). When you generate pick slips for the order, the system bills the subscription item immediately and indicates on the pick slip that the subscription is shipping separately. See Working with Item Subscriptions (WISB).

Membership items: The system creates a separate pre-generated pick for a membership item (the Membership field for the item is selected). When you generate pick slips for the order, the system bills the membership item immediately and indicates on the pick slip that the membership is shipping separately.

| Field | Pick Slip Preparation Update |

|---|---|

|

Pick control # |

The system assigns the next available number from the PCH Control # number assignment wheel. NOTE: The system assigns a new pick control number when a pre-generated pick is created, including when a pre-generated pick is deleted and then recreated because the order was updated by a user or the system. |

|

Pick status |

Defines whether the pre-generated pick requires authorization during pick slip generation. G Generated No Authorization = The pick requires authorization during pick slip generation. The system updates the pick status to G if:

H Generated Has Authorization = The pick can bypass authorization processing during pick slip generation. The system updates the pick status to H if:

NOTE: When Selecting Pre-Generated Picks for Pick Slip Generation, the system looks at Authorization History to determine if any picks in an H Generated Has Authorization status are associated with an expired authorization, and if so, the system changes the status of the pick to G Generated No Authorization. |

|

Billing batch # |

The system does not assign a billing batch number to a pre-generated pick; the system assigns a billing batch number to the pick during pick slip generation; see Selecting Pre-Generated Picks for Pick Slip Generation. |

|

Date and Time of last update |

The date and time when the system created the pre-generated pick. The system updates this field when a pre-generated pick is created, including when a pre-generated pick is deleted and then recreated because the order was updated by a user or the system. |

|

Generation type |

Defines whether the pick contains an item that requires special handling or whether the pick is billed immediately after pick slip generation. R Regular = The pick does not contain an item that requires special handling and is billed after the shipment is confirmed. S Special Handling = The pick contains an item that requires special handling and is billed after the shipment is confirmed. I Bill Immediately = The pick is confirmed and billed immediately after pick slip generation. |

|

PO # |

The purchase order number assigned to the order. |

|

Merch |

The merchandise amount on the pre-generated pick. |

|

Freight |

The freight amount on the pre-generated pick. |

|

Add’l freight |

The additional freight amount on the pre-generated pick. |

|

Add’l charges |

The additional charge amount on the pre-generated pick. |

|

Handling |

The handling amount on the pre-generated pick. |

|

Tax |

The tax amount on the pre-generated pick. |

|

GST |

The GST tax amount on the pre-generated pick. |

|

PST |

The PST tax amount on the pre-generated pick. |

|

Total Order Amount |

The total amount on the pre-generated pick. |

|

First pick |

Indicates whether this is the first pick for the order. Y = This is the first pick for the order. N = This is not the first pick for the order. |

|

Order # |

The order number associated with the pre-generated pick. |

|

Ship to # |

The order ship to associated with the pre-generated pick. |

|

Ship via code |

The shipper assigned to the pre-generated pick. |

|

Last update by user |

The process that created the Pick Control Header record. |

|

Customer # |

The sold to customer number on the order. |

|

Warehouse |

The warehouse assigned to the pre-generated pick. The system uses this warehouse during Pick Slip Allocation Processing. |

|

Drop point |

The drop point specified for the warehouse or for the warehouse/ship via/SCF combination if you are using zone skipping. See the Work with Ship Via Indicia Screen for an overview. |

|

Country |

The country code for the shipping address on the pick. |

|

State |

The state code for the shipping address on the pick. |

|

Prefix First Name Initial Last Name Suffix |

The prefix, first name, middle initial, last name and suffix of the ship to customer on the pick. |

|

Apartment |

The apartment for the shipping address on the pick. |

|

Address line 2 |

The second address line for the shipping address on the pick. |

|

City |

The city for the shipping address on the pick. |

|

Zip |

The postal code for the shipping address on the pick. |

|

Delivery code |

Defines whether the shipping address is a residential or business address. B = Business address. R = Residential address. N = No distinction. |

|

PO Box? |

Defines whether the shipping address is a post office box. Y = The address is a post office box. N = The address is not a post office box. |

Pick Control Detail Updates for Pre-Generated Picks

Pick Slip Preparation updates the following fields in the Pick Control Detail table for pre-generated picks. The remaining fields are not updated until you run pick slip generation for the order. The system creates a record in the Pick Control Detail table for each shippable line on the order that qualifies for pick slip preparation.

Backordered and drop ship items: The system does not create a Pick Control Detail record for any items on backorder or that are flagged as drop ship until you run pick slip generation for the order.

Non-inventory items: The system:

- Does not create a pre-generated pick for a non-inventory item if all other items on the order are backordered; when one or more backordered items are available, the system creates a pre-generated pick for the non-inventory item as well as for the available item(s).

- Creates a pre-generated pick for a non-inventory item if all other items on the order are not selected for pick slip preparation; see Selecting Order Lines for Pick Slip Preparation.

Coordinate-grouped items: The system does not create a pre-generated pick for order lines that are assigned the same coordinate group number until all of the coordinate grouped lines are eligible for pick slip preparation.

| Field | Pick Slip Preparation Update |

|---|---|

|

Line # |

The pick line number assigned to a shippable order line on the order. |

|

Original qty printed |

The quantity available to ship on the pick. |

|

Qty printed |

The same as the original quantity printed. |

|

Affect inventory |

Defines whether shipping the item affects the inventory count. Y = Affect inventory. N = Do not affect inventory. |

|

Price |

The single-unit selling price of the item after applying any repricing or discounts. |

|

PCD Extension |

The selling price times the printed quantity. |

|

Freight charge |

The freight charge for the item on the pick. Included only if there is a printed quantity and the source code uses an item-level freight method. |

|

Spec Handling $ |

The total special handling charges for the item. |

|

Gift Charge |

The total giftwrap charge. |

|

Qty Ordered |

The original quantity ordered for the order detail line. |

|

Tax |

The total tax amount for the item on the pick. |

|

GST |

The total GST tax amount for the item on the pick. |

|

PST |

The total PST tax amount for the item on the pick. |

|

Order # |

The order number associated with the pick. |

|

Ship to # |

The order ship to associated with the pick. |

|

Seq # |

The order line sequence number. |

|

ITM Number |

A code for the item on the pick. |

|

SKU Code |

A code for the item’s unique characteristics, such as color and size, on the pick. |

|

Add’l chg code |

The additional charge code related to special handling for the item on the pick. |

Removing Pick Slip Preparation from an Order

The system REMOVES any pick slip preparation that may have already occurred when you or the system changes an order; see When is Pick Slip Preparation Performed? to review when the system removes pick slip preparation from an order.

The system:

- Deletes the pre-generated picks for the order in the Pick Control Header, Pick Control Detail, Pick Control Label, and Pick Stored Value Card tables that are in a G Generated No Authorization or H Generated Has Authorization status, across all order ship tos.

- Resets the Qty printed and Qty remaining fields for the order in the Reserved Order Lines table.

- If pick slips have not been generated for the order and the order

contains an online authorization:

- Retains records for the order in the Authorization History table that are in a status other than G Generated.

- Updates the Amount authorized in the Order Payment Method table to 0.00.

- Creates a record in the Void Auths table for the amount authorized in the Authorization History table.

- If pick slips have not been generated for the order and the order

contains a manual authorization:

- Deletes records for the order in the Authorization History table that are in a G Generated status (the system retains records in any other status).

- Removes any message for the order in the Order Transaction History table regarding a manual auth detected.

- Restores any manual authorization information for the order in the Order Payment Method table.

- Deletes any records for the order payment in the Void Auths table.

Note:

After removing pick slip preparation from an order and updating the order with any changes, the system evaluates the order to determine if it is eligible for pick slip preparation, and if it is, the system RE-APPLIES pick slip preparation to the order; see Pick Slip Preparation when an Order is Maintained.Pick Slip Preparation Examples

Examples of how the system performs pick slip preparation when an order is created or updated are described below.

- Example 1: Pick Slip Preparation when Order is Created with no Authorization

- Example 2: Pick Slip Preparation when Order is Created with Online Authorization

- Example 3: Pick Slip Preparation when Order is Created with Manual Authorization

- Example 4: Pick Slip Preparation when an Order is Maintained

Example 1: Pick Slip Preparation when Order is Created with no Authorization

You create an order that contains the following information:

Order Header:

- Arrival date = today’s date

- Ship via = 1

Order Detail:

| Line# | Item | Status | Arrival Date | Reserve Qty | Ship Via | Whs |

|---|---|---|---|---|---|---|

|

1 |

A1 |

Open |

today’s date |

1 |

1 |

1 |

|

2 |

B1 |

Open |

today’s date |

2 |

1 |

1 |

|

3 |

C1 |

Backorder |

today’s date |

0 |

1 |

1 |

Order Payment:

| Pay category | Authorization Date | Authorization Amount | |

|---|---|---|---|

|

2 Credit Card |

blank |

blank |

Pick slip preparation: When you accept the order, the order does not go on hold. The system:

Creates one pre-generated pick for the order in a G Generated No Authorization status:

| Pick Control# | Status | Last Update | Gen Type | First Pick | Whs | Ship Via |

|---|---|---|---|---|---|---|

|

5051 |

G |

Current date |

R Regular |

Y |

1 |

1 |

Creates two pick control details for the pre-generated pick:

| Pick Control# | Item | Qty Printed |

|---|---|---|

|

5051 |

A1 |

1 |

|

5051 |

B1 |

2 |

Updates the Qty printed and Qty Remaining for the reserved order lines on the order:

| Line# | Whs | Reserved | Printed | Remaining | Reservation Date |

|---|---|---|---|---|---|

|

1 |

1 |

1 |

1 |

0 |

today’s date |

|

2 |

1 |

2 |

2 |

0 |

today’s date |

Pick slip generation: When you process pick slip generation for the order, the system:

- Assigns a billing batch number to the pick.

- Updates the Date last update to the date when pick slip generation is run.

- Updates the Date printed to the date when pick slip generation is run.

- Updates the Status of the pick from G Generated No Authorization to 1 Waiting for Authorization.

- Performs batch authorization for the pick; see Authorizations During Pick Slip Generation.

- Determines which item/locations to reserve stock from in order to fulfill the quantity required for the pick; see Allocating Stock.

- Sorts the picks so that they generate and print in the correct order. The sort also determines when the system creates a new pick slip PDF document for the picks in the pick slip generation run. See Sorting Pick Slips into Separate PDF Documents and Pick Slip Sort within a Pick Slip PDF Document.

- Groups the picks into documents for printing; see Generating and Printing Pick Slips.

Example 2: Pick Slip Preparation when Order is Created with Online Authorization

You create an order that contains the following information:

Order Header:

- Arrival date = today’s date

- Ship via = 1

- Order total = 100.00

Order Detail:

| Line# | Item | Status | Arrival Date | Reserve Qty | Ship Via | Whs |

|---|---|---|---|---|---|---|

|

1 |

A1 |

Open |

today’s date |

1 |

1 |

1 |

|

2 |

B1 |

Open |

today’s date |

2 |

1 |

1 |

|

3 |

C1 |

Backorder |

today’s date |

0 |

1 |

1 |

Order Payment:

| Pay category | Authorization Date | Authorization Amount |

|---|---|---|

|

2 Credit Card |

today’s date |

110.00 (10.00 greater than order amount) |

Pick slip preparation: When you accept the order, the order does not go on hold. The system:

Creates one pre-generated pick for the order in an H Generated Has Authorization status:

| Pick Control# | Status | Last Update | Gen Type | First Pick | Whs | Ship Via |

|---|---|---|---|---|---|---|

|

5052 |

H |

Current date |

R Regular |

Y |

1 |

1 |

Creates two pick control details for the pre-generated pick:

| Pick Control# | Line# | Qty Printed | Item |

|---|---|---|---|

|

5052 |

1 |

1 |

A1 |

|

5052 |

2 |

2 |

B1 |

Updates the Qty printed and Qty Remaining for the reserved order lines on the order:

| Line# | Whs | Reserved | Printed | Remaining | Reservation Date |

|---|---|---|---|---|---|

|

1 |

1 |

1 |

1 |

0 |

today’s date |

|

2 |

1 |

2 |

2 |

0 |

today’s date |

Updates authorizations history for the order:

| Status | Auth Amt | Auth# | Auth Date |

|---|---|---|---|

|

A Authorized |

110.00 |

TST1 |

today’s date |

Updates the Order Payment Method:

- Removes the Authorization date, Authorization number, and Manual authorization amount.

- Updates the Amount authorized with the authorization amount.

Creates a Void Auths record for 10.00 since the authorization amount (110.00) is greater than the order total (100.00).

Pick slip generation: When you process pick slip generation for the order, the system:

- Assigns a billing batch number to the pick.

- Updates the Date updated to the date when pick slip generation is run.

- Updates the Date printed to the date when pick slip generation is run.

- Updates the Status of the pick from H Generated Has Authorization to 2 Authorized.

- Skips batch authorization for the pick.

- Determines which item/locations to reserve stock from in order to fulfill the quantity required for the pick; see Allocating Stock.

- Sorts the picks so that they generate and print in the correct order. The sort also determines when the system creates a new pick slip PDF document for the picks in the pick slip generation run. See Sorting Pick Slips into Separate PDF Documents and Pick Slip Sort within a Pick Slip PDF Document.

- Groups the picks into documents for printing; see Generating and Printing Pick Slips.

Example 3: Pick Slip Preparation when Order is Created with Manual Authorization

You create an order that contains the following information:

Order Header:

- Arrival date = today’s date

- Ship via = 1

- Order total = 100.00

Order Detail:

| Line# | Item | Status | Arrival Date | Reserve Qty | Ship Via | Whs |

|---|---|---|---|---|---|---|

|

1 |

A1 |

Open |

today’s date |

1 |

1 |

1 |

|

2 |

B1 |

Open |

today’s date |

2 |

1 |

1 |

|

3 |

C1 |

Backorder |

today’s date |

0 |

1 |

1 |

Order Payment:

| Pay category | Authorization Date | Authorization Amount |

|---|---|---|

|

2 Credit Card |

today’s date |

110.00 (10.00 greater than order amount) |

Pick slip preparation: When you accept the order, the order does not go on hold. The system:

Creates one pre-generated pick for the order in an H Generated Has Authorization status:

| Pick Control# | Status | Last Update | Gen Type | First Pick | Whs | Ship Via |

|---|---|---|---|---|---|---|

|

5053 |

H |

Current date |

R Regular |

Y |

1 |

1 |

Creates two pick control details for the pre-generated pick:

| Pick Control# | Line# | Qty Printed | Item |

|---|---|---|---|

|

5053 |

1 |

1 |