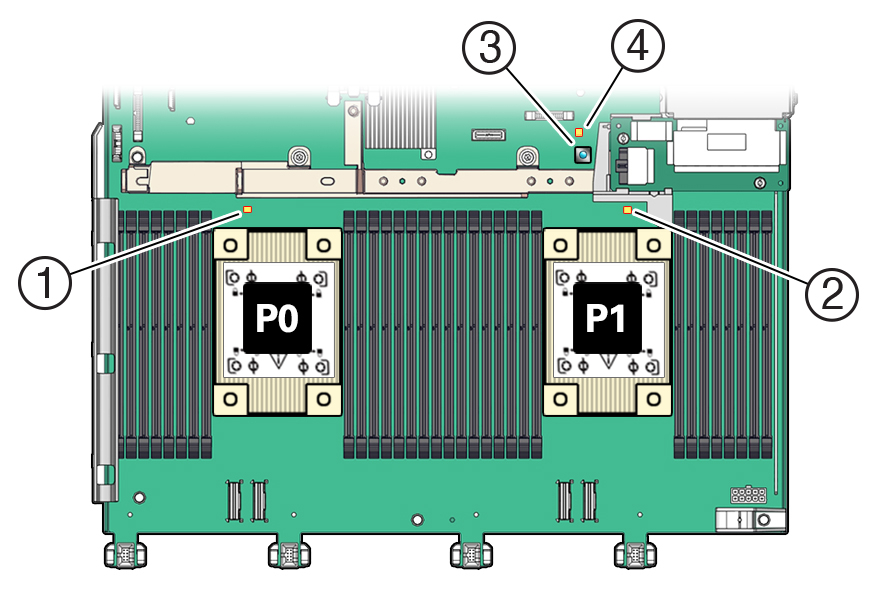

12 Servicing Processors (FRU)

The following section describes how to service processors. Processors are field-replaceable units (FRUs). For more information about FRUs, see Illustrated Parts Breakdown and Field-Replaceable Units.

Caution:

Processors must be removed and replaced only by authorized Oracle Service personnel.Caution:

Ensure that all power is removed from the server before removing or installing a processor. You must disconnect the power cables from the system before performing these procedures.Caution:

These procedures require that you handle components that are sensitive to electrostatic discharge. This sensitivity can cause the component to fail. To avoid damage, ensure that you follow electrostatic discharge safety measures and antistatic practices. See Electrostatic Discharge Safety.Note:

On single-processor systems, processor socket 1 (P1) is shipped without a heatsink and processor filler cover. To protect the delicate processor socket pins, do not remove the processor cover that was installed on the motherboard.This section covers the following topics:

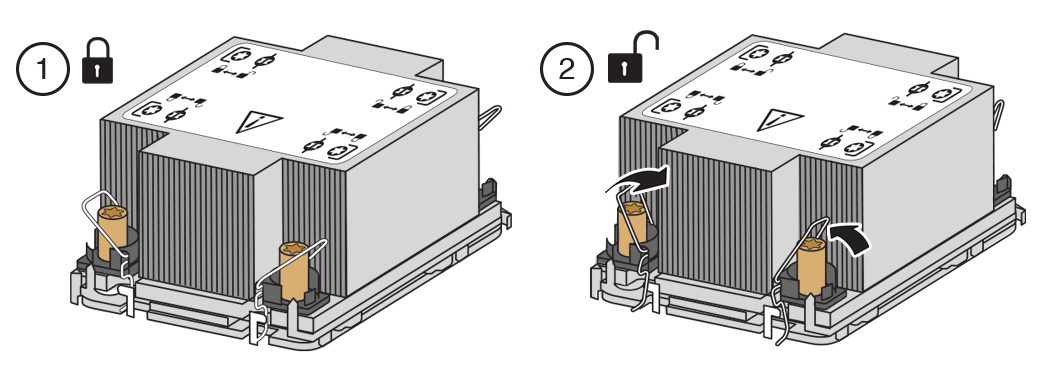

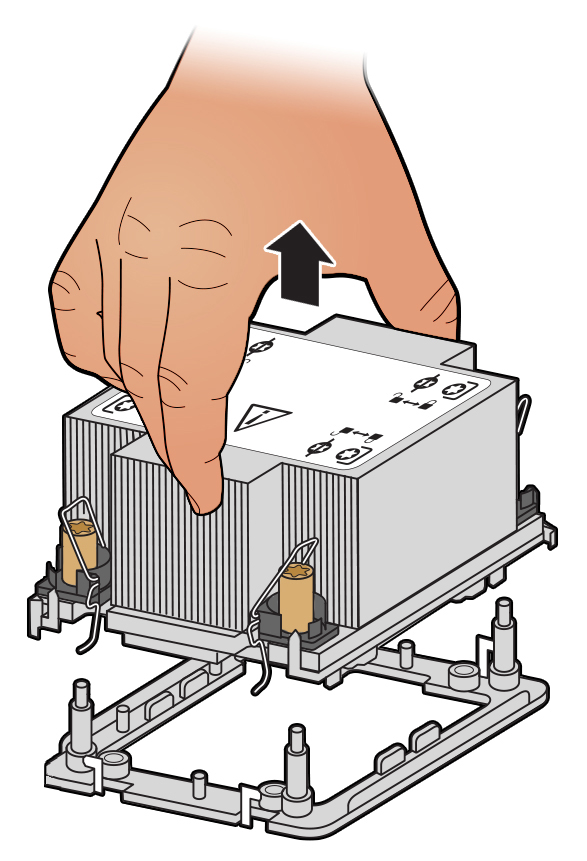

Identify and Remove a Processor

Caution:

Whenever you remove a processor, replace it with another processor and reinstall the processor heatsink; otherwise, the server might overheat due to improper airflow. See Install a Processor.-

Use an antistatic wrist strap and a work space with an antistatic mat.

-

Use ESD (not latex or vinyl) gloves, if possible, when handling the processor.

-

Be careful not to touch the processor socket pins.

Caution:

The processor socket pins are very fragile. A light touch can bend the processor socket pins beyond repair. -

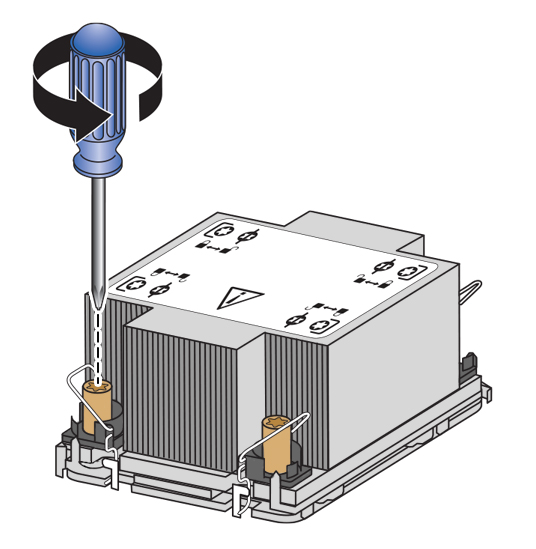

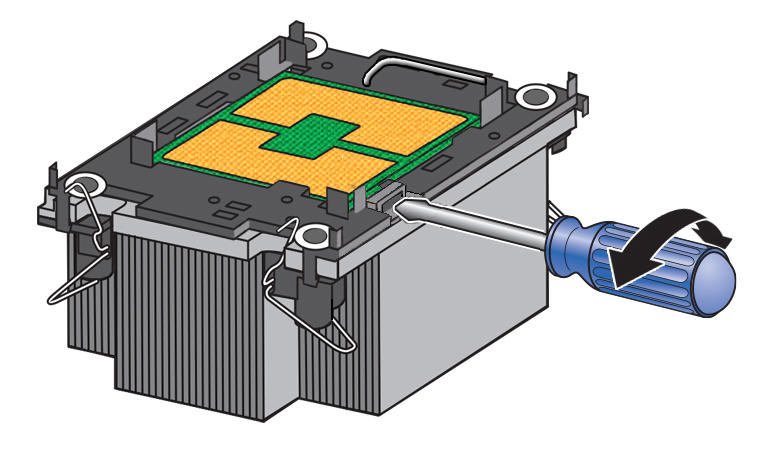

Obtain a medium flat blade screwdriver

-

Obtain a T30 Torx driver or bit

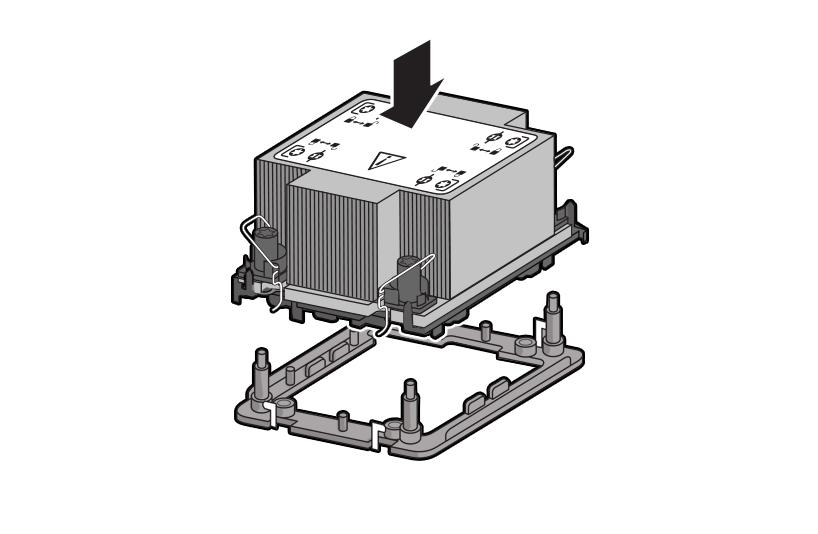

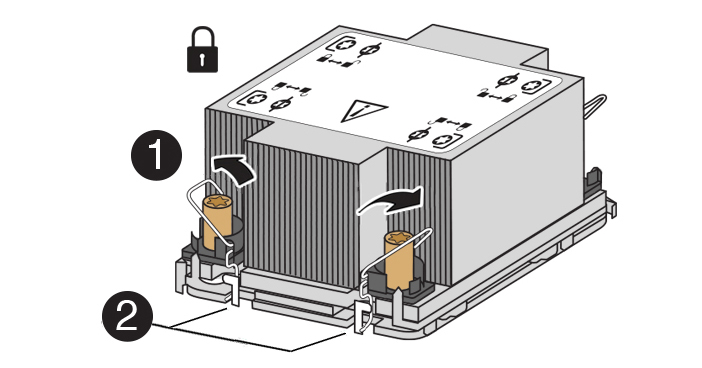

Install a Processor

-

Use an antistatic wrist strap and a work space with an antistatic mat.

-

Use ESD (not latex or vinyl) gloves, if possible, when handling the processor.

-

Be careful not to touch the processor socket pins.

Caution:

The processor socket pins are very fragile. A light touch can bend the processor socket pins beyond repair. -

Obtain a preset or adjustable torque driver set to 8 in-lbf (inch-pound force) with a T30 Torx bit.

Caution:

Using an incorrect torque setting or driver can damage a processor-heatsink module. -

If you are replacing a processor, ensure that the replacement processor is identical to the processor that was removed. For a list of supported processors, see Product Description.