| Skip Navigation Links | |

| Exit Print View | |

|

Sun Server X2-4 (formerly Sun Fire X4470 M2) Service Manual |

1. Sun Server X2-4 Service Manual Overview

1.1.7 Summary of Supported Components and Capabilities

1.2 Server Front Panel Features

1.3 Server Back Panel Features

1.4 Performing Service Related Tasks

2. Preparing to Service the Sun Server X2-4

2.1 Location of Replaceable Components

2.2 Tools and Equipment Needed

2.3 Performing Electrostatic Discharge and Static Prevention Measures

2.3.1 Using an Antistatic Wrist Strap

2.4 Positioning the Server for Maintenance

Extend the Server to the Maintenance Position

2.5 Releasing the Cable Management Arm

Power Off the Server Using the Service Processor Command-Line Interface

2.7 Removing the Server Top Cover

2.8 Removing or Installing Filler Panels

2.9 Attaching Devices to the Server

3. Servicing CRU Components That Do Not Require Server Power Off

3.1 Servicing Disk Drives (CRU)

3.1.1 Disk Drive Status LED Reference

3.1.2 Removing and Installing Disk Drives and Disk Drive Filler Panels

Remove a Disk Drive Filler Panel

Install a Disk Drive Filler Panel

3.2 Servicing Fan Modules (CRU)

3.2.2 Fan Module LED Reference

3.2.3 Detecting Fan Module Failure

3.2.4 Removing and Installing Fan Modules

3.3 Servicing Power Supplies (CRU)

3.3.1 Power Supply LED Reference

3.3.2 Detecting a Power Supply Failure

3.3.3 Removing and Installing Power Supplies

4. Servicing CRU Components That Require Server Power Off

4.1 Servicing Memory Risers and DIMMs (CRU)

4.1.1 CPUs, Memory Risers, and DIMMs Physical Layout

4.1.2 Memory Riser Population Rules

4.1.3 Memory Riser DIMM Population Rules

4.1.4 Memory Performance Guidelines

4.1.4.1 Recommended Memory Placement

4.1.8 Removing and Installing Memory Risers, DIMMs, and Filler Panels

Remove a Memory Riser Filler Panel

Remove a Memory Riser and DIMM

Install Memory Risers and DIMMs

4.2 Servicing PCIe Cards (CRU)

4.2.1 PCIe Card Configuration Rules

4.2.2 PCIe Cards With Bootable Devices

4.2.3 Avoiding PCI Resource Exhaustion Errors

4.2.4 Removing and Installing PCIe Cards and PCIe Card Filler Panels

Remove a PCIe Card Filler Panel

Install a PCIe Card Filler Panel

4.3 Servicing the DVD Drive and DVD Driver Filler Panel (CRU)

Remove the DVD Drive or DVD Drive Filler Panel

Install the DVD Drive or DVD Drive Filler Panel

4.4 Servicing the System Lithium Battery (CRU)

5.1 Servicing the CPU and Heatsink (FRU)

5.1.2 Removing and Installing a Heatsink Filler Panel, CPU Cover Plate, Heatsink, and CPU

5.2 Servicing the Fan Board (FRU)

5.3 Servicing the Power Supply Backplane (FRU)

Remove the Power Supply Backplane

Install the Power Supply Backplane

5.4 Servicing the Disk Drive Backplane (FRU)

Remove the Disk Drive Backplane

Install the Disk Drive Backplane

5.5 Servicing the Motherboard (FRU)

6. Returning the Server to Operation

6.1 Replacing the Server Top Cover

6.2 Returning the Server to the Normal Rack Position

Return the Server to the Normal Rack Position

7. Servicing the Server at Boot Time

7.3 Default BIOS Power-On Self-Test (POST) Events

7.4 BIOS POST F1 and F2 Errors

7.5 How BIOS POST Memory Testing Works

7.6 Ethernet Port Device and Driver Naming

7.6.1 Ethernet Port Booting Priority

7.8 Performing Common BIOS Procedures

7.8.1 Configuring Serial Port Sharing

8. Troubleshooting the Server and ILOM Defaults

8.1 Troubleshooting the Server

8.2.1 Diagnostic Tool Documentation

8.3 Using the Preboot Menu Utility

8.3.1 Accessing the Preboot Menu

8.3.2 Restoring Oracle ILOM to Default Settings

8.3.3 Restoring Oracle ILOM Access to the Serial Console

8.3.4 Restoring the SP Firmware Image

8.3.5 Preboot Menu Command Summary

8.5 Locating the Chassis Serial Number

A.3 Environmental Requirements

B.2 BIOS Advanced Menu Selections

B.3 BIOS PCIPnP Menu Selections

B.5 BIOS Security Menu Selections

B.6 BIOS IO/MMIO Menu Selections

B.7 BIOS Chipset Menu Selections

C.3 Gigabit-Ethernet Connectors

C.4 Network Management Port Connector

C.6 Serial Attached SCSI (SAS) Connector

D. Getting Server Firmware and Software

D.1 Firmware and Software Updates

D.2 Firmware and Software Access Options

D.3 Available Software Release Packages

D.4 Accessing Firmware and Software

Download Firmware and Software Using My Oracle Support

D.4.1 Requesting Physical Media

D.4.2 Gathering Information for the Physical Media Request

| Caution - These procedures require that you handle components that are sensitive to static discharge. This sensitivity can cause the component to fail. To avoid damage, ensure that you follow antistatic practices as described in 2.3 Performing Electrostatic Discharge and Static Prevention Measures. |

When replacing or upgrading a DIMM on the server you should consider the following:

Physical layout of the CPUs, memory risers, and DIMMs

Memory riser population rules

Memory riser DIMM population rules

Rules for installing DIMMs across memory risers

DIMM rank classifications labels

Instructions for installing a DIMM

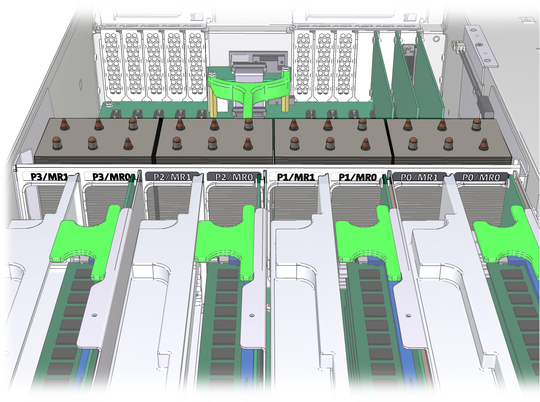

The physical layout of the CPUs, memory risers, and DIMMs is shown in CPU and Memory Riser Layout and Memory Riser DIMMs Physical Layout and Population Order.

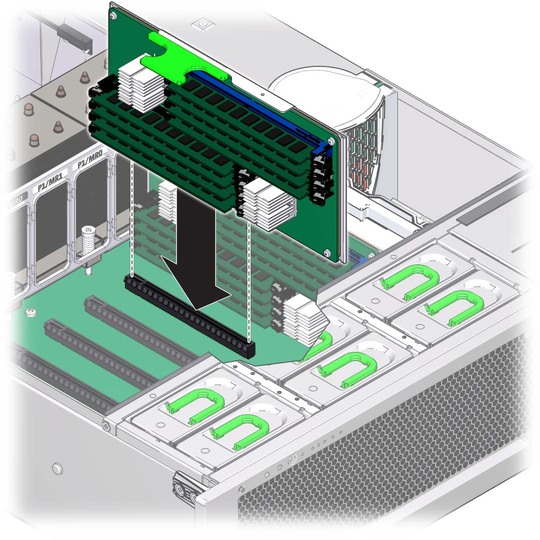

Figure 4-1 CPU and Memory Riser Layout

Note - Only memory risers that are labeled “V2 Memory Riser” are supported in the Sun Server X2-4. Before installing memory risers in the server, ensure that the memory riser contains this label.

The system firmware checks if the installed CPUs are for the Sun Server X2-4. The system firmware raises a fault for memory risers whose model belongs with the other family of CPUs.

The memory riser population rules for the Sun Server X2-4 are as follows:

A maximum of two memory risers (numbered MR0 and MR1) are supported per CPU, thus allowing up to eight memory risers in a 4-CPU system, or up to four memory risers in a 2-CPU system.

Each memory riser slot in the server chassis must be filled with either a memory riser or filler panel, and each memory riser must be filled with DIMMs and/or DIMM filler panels. For example, in 2-CPU systems, empty CPU sockets (P1 and P3) must have associated memory riser slots populated with two riser filler panels per CPU.

Performance-oriented configurations should be configured with two memory risers per CPU. In configurations that do not require two memory risers per CPU, the following guidelines should be followed:

First populate riser slot MR0 for each CPU, starting with the lowest numbered CPU (P0).

The populate riser slot MR1 for each CPU, starting with the lowest numbered CPU (P0).

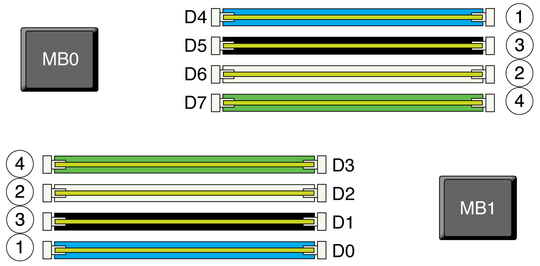

Figure 4-2 Memory Riser DIMMs Physical Layout and Population Order

The memory riser DIMM population rules for the Sun Server X2-4 are as follows:

Maximum memory operating speed is 1066 MHz. This also applies to supported DIMMs rated for higher speeds.

Supported DIMMs include single-, dual-, or quad-rank 4 GB, 8 GB, 16 GB and 32 GB JEDEC˘2013standard, DDR3 low voltage ECC RDIMMs.

All DIMMs on a CMOD must be the same density and organization.

Note - Do not mix dual-rank 16 GB DIMMs with quad-rank 16 GB DIMMs on a CMOD. Mixing DIMMs of different rank or density degrades performance.

Single-rank DIMMs (marked 1Rx8) and dual-rank DIMMs (marked 2Rx4) do not include heat spreaders.

Quad-rank DIMMs are marked 4Rx4 and include heat spreaders. DIMMs with heat spreaders have two U-shaped metal clips on the top of the DIMM.

Each memory riser supports up to 8 DIMMs, with a maximum 64 DIMMs for a 4-socket Sun Server X2-4.

DIMM slots are color coded with the following population order:

Blue

White

Black

Green

DIMM slots must be populated in matching pairs of identical DIMMs (from the same memory kit) within a processor.

The recommended DIMM population order, as depicted in Memory Riser DIMMs Physical Layout and Population Order is:

D0/D4

D2/D6

D1/D5

D3/D7

Install quad-rank DIMMs before dual-rank DIMMs on the same riser. Specifically, a DRAM channel with both rank types must have the quad-rank DIMM in the D0/D4 or D2/D6 slot.

Note - When a mixed quad-rank DIMM and dual or single rank DIMM are on the same memory riser, the quad-rank DIMM should be installed in slot0 of each channel.

Meeting these guidelines will provide the best system performance. Guidelines are listed in decreasing importance.

Provide some DIMMs on every memory riser.

Provide DIMMs on every DRAM channel (at least 4 DIMMs per memory riser).

For each CPU, have equal total gigabytes on the MR0 and MR1 risers. Memory bandwidth is 5% higher when all pairs of risers have balanced capacity.

Spread the memory capacity evenly across the CPUs so the operating system can distribute large memory tasks better.

Avoid mixing dual-rank and quad-rank DIMMs in the same memory riser.

For the Sun Server X2-4, the operating speed of the DIMMs does not decrease as more DIMMs are installed. For best memory performance, follow these simple guidelines to add or replace DIMMs in the server. Use one or more sizes of DIMMs, with an even number of DIMMs of each size.

Using the largest-capacity DIMMs, add two DIMMs per riser, starting at P0/MR0, continuing through P3/MR1, and then beginning again at P0/MR0 if necessary, until all of the largest-capacity DIMMs are placed.

For installations with one DIMM size, all DIMMs will be placed in this step. For installations with additional DIMMs of different sizes, continue to the next guideline step.

If you are adding or replacing quad-rank (16GB) DIMMs, they can be installed only in D0/D4 slots or D2/D6 slots, or else in DRAM channels where those slots already contain 16GB DIMMs.

Using DIMMs of the next largest capacity, add two DIMMs per riser, starting with risers with the fewest DIMMs and proceeding from P0/MR0, continuing through P3/MR1, and then beginning again at P0/MR0 if necessary, until there are no more DIMMs of this size, or all risers have four DIMMs.

As long as any riser has fewer than four DIMMs, keep repeating this step with the DIMMs of decreasing capacity. When all risers have four DIMMs, continue to the next guideline step.

Using DIMMs of the next largest capacity, add two DIMMs per riser to risers with the least total gigabytes. Start from P0/MR0, continuing through P3/MR1, and then begin again at P0/MR0 is necessary.

Repeat guideline step 3 with all remaining DIMMs, in decreasing order of DIMM capacity, until all DIMMs are placed.

The eight DIMMs supported on each memory riser card in the Sun Server X2-4 are divided into two logical DDR3 channels. The first logical channel contains DIMMs installed in slots D0, D1, D4 and D5. The second logical channel contains DIMMs installed in slots D2, D4, D6 and D7.When one or more DIMMs within a logical DDR3 channel are faulted, all four DIMMs within that logical channel will be disabled by BIOS on subsequent boots. This isolates the faulty component from the system to ensure that proper operation is not compromised by the presence of the faulty component.

Initially supported DIMMs for the Sun Server X2-4 are PC3L-type RDIMMs, which are DDR3 low-voltage DIMMs. Supported DIMM Size and Organization identifies supported DIMM sizes.

Table 4-1 Supported DIMM Size and Organization

|

The Sun Server X2-4 does not support the following DIMMs:

MetaRAMs

LR-DIMMs or UDIMM

DIMMs using 256 Mb or 512 Mb DRAM technologies

DDR3-800 MHz RDIMMs

DDR3-978 MHz RDIMMs

Use the following procedures to remove and install memory risers, DIMMs, and filler panels.

See 2.3 Performing Electrostatic Discharge and Static Prevention Measures.

| Caution - Whenever you remove a memory riser filler panel, replace it with another filler panel or a memory riser; otherwise, the server might overheat due to improper airflow. |

See 2.3 Performing Electrostatic Discharge and Static Prevention Measures.

The filler panel is partially ejected from the socket.

| Caution - Whenever you remove a DIMM filler panel, replace it with another filler panel or a DIMM; otherwise, the server might overheat due to improper airflow. |

See 2.3 Performing Electrostatic Discharge and Static Prevention Measures.

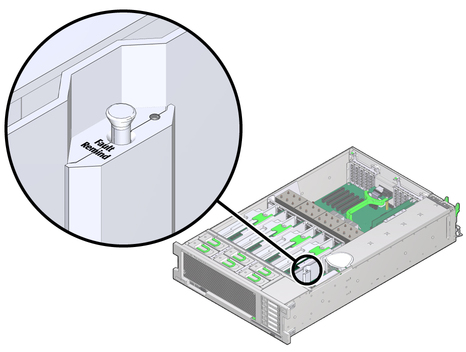

Note - Located above the Fault Remind button is the Fault Remind button Power LED. When the Fault Remind button is pressed, the Power LED illuminates (green) to indicate that the remind circuitry is working correctly.

Figure 4-3 Fault Remind Button on the Air Divider

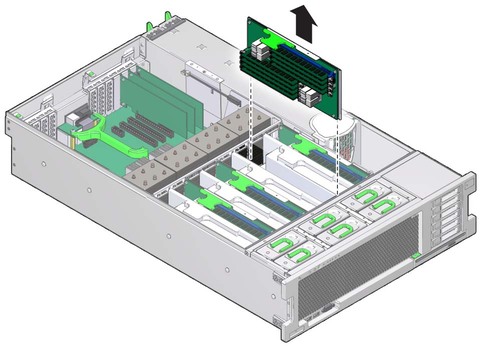

Figure 4-4 Removing the Memory Riser

The DIMM is partially ejected from the socket.

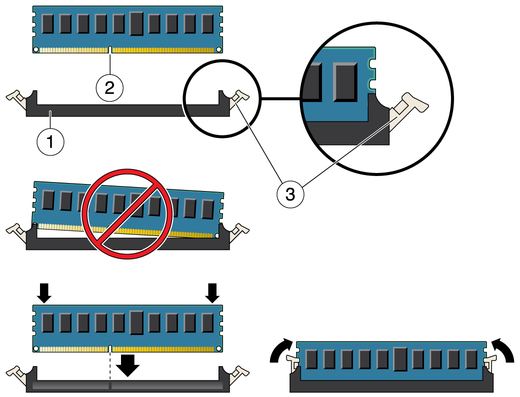

Figure 4-6 DIMM Socket Release and Alignment

Figure Legend

1 DIMM connector slot

2 DIMM connector key

3 DIMM ejector lever

| Caution - Whenever you remove a memory riser or DIMM, you should replace it with another memory riser or a DIMM or a filler panel; otherwise, the server might overheat due to improper airflow. |

| Caution - Be sure to install DIMMs in matched pairs of identical DIMM types (same part number). |

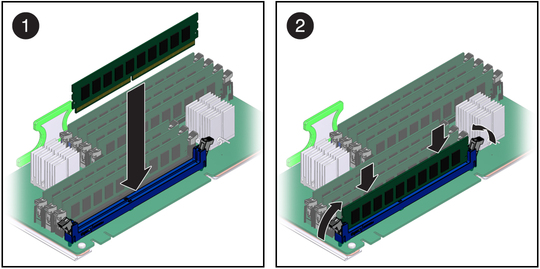

Refer to Installing DIMMs and Installing a Memory Riser Module when completing the following procedure.

Align the notch in the DIMM with the key in the connector. The notch ensures that the DIMM is oriented correctly.

Figure 4-7 Installing DIMMs

If the DIMM does not easily seat into the connector, verify that the notch in the DIMM is aligned with the key in the connector as shown in DIMM Socket Release and Alignment. If the notch is not aligned, damage to the DIMM might occur.

Figure 4-8 Installing a Memory Riser Module