Chapter 58: Replenish Warehouses Overview

Purpose: This chapter provides an overview of the Replenish Warehouses function.

What this function does: You can use the Replenish Warehouses function to move inventory from one warehouse to another to replenish the target warehouse.

For example, you can use this function to restock a retail store from a distribution warehouse, or to restock regional shipping warehouses from a central distribution center.

There are two methods available in CWDirect for replenishing warehouses:

• Standard process: This process assumes that you maintain inventory information in CWDirect for each warehouse you need to replenish. The standard process evaluates the replenishment requirement of the 'To' warehouse and allocates stock in the 'From' warehouse based on this inventory information. You create, work with, and confirm replenishment requests solely through the Replenish Warehouses function.

• Outlet transfer process: This process assumes that each warehouse you are replenishing represents a separate retail outlet that maintains its own inventory information. As a result, the instructions for the replenishment request originate not from the 'To' warehouse information in CWDirect, but from purchase order information provided by the outlets themselves. In addition to the Replenish Warehouses function, additional menu options enable you to process these requests.

In this chapter:

• Standard Warehouse Replenishment

• Outlet Transfer Replenishment

Standard Warehouse Replenishment

The standard replenishment process:

• analyzes the inventory level in the warehouse being replenished (the 'To' warehouse) to determine if it requires additional inventory to reach capacity.

• analyzes the inventory levels in pickable locations in the warehouse being used to replenish the warehouse (the 'From' warehouse) to determine the amount of inventory available to transfer.

• allocates the inventory to replenish in the locations in the 'From' warehouse where it should be picked, increasing the Printed quantity and Reserve transfer quantity fields to reflect the allocated quantity.

• processes transfer (T) inventory transactions when you confirm the replenishment request. Inventory in the locations in the 'From' warehouse is decreased; inventory in the auto-restock location in the 'To' warehouse is increased. The printed quantity and reserve transfer quantity fields are decreased, and any resulting postings to the general ledger interface are made at this time as well.

• allows you to use the confirmed Warehouse Replenishment Control file to place the inventory in actual locations in the 'To' warehouse if the Receive restock transfers field for the warehouse is set to Y.

You determine how and when to replenish items within warehouses by completing fields in the Warehouse file and the Item Warehouse file.

You can run Creating a Warehouse Replenishment Request at any time, or multiple times throughout the day. You can include multiple warehouses in the same replenishment run. You can select specific items for replenishment if you are replenishing only one warehouse. You can also review an existing replenishment request before you confirm it, and "unallocate" an item if you do not want to fulfill the request for the item at this time.

Warehouse file: Complete the following fields for the 'To' warehouse to indicate where to place replenishment transfers initially, and whether you will be using CWDirect to put the stock away in specific locations.

Auto restock location: This field specifies the location in the 'To' warehouse where the system should place inventory when you confirm a replenishment request. The system transfers the inventory from the location where it was picked in the 'From' warehouse to the auto-restock location in the 'To' warehouse.

Receive restock transfers: Set this field to Y to indicate that the replenishment request should remain on the system after you confirm it. If the request remains on the system, you can use option 7 in the Replenish Warehouses function to place stock, or transfer the stock from the auto-restock location to its ultimate location after confirmation. The system will delete the replenishment request when this placement is complete. If you set this field to N, the system deletes the request after you confirm it; you will need to use an inventory transaction to place the stock.

Item Warehouse file: The following fields in the Item Warehouse file determine which items will be replenished and the replenishment quantity.

Reservation freeze: This field determines whether the item will be evaluated for replenishment. The item must be reservable in both the warehouse being replenished (the 'To' warehouse) and in the warehouse that is being used for the replenishment (the 'From' warehouse) to be evaluated for replenishment.

Min qty, Max qty, Reorder qty: If the item is eligible for replenishment, the system uses these fields to determine the replenishment quantity for the 'To' warehouse.

The minimum number of units that should be kept in the warehouse is defined in the Min qty field. When the on-hand quantity of the item in the warehouse falls below this amount, the item is eligible for replenishment. If there is a quantity in the Reorder qty field, the system will attempt to replenish this amount. If you do not specify a reorder quantity, the system will attempt to replenish the difference between the on-hand quantity and the Max qty field.

You should not set up the Min qty and Max qty in your 'From' warehouse if you plan to replenish all warehouses at once.

Protected qty: This field for the 'From' warehouse is used in the replenishment calculation. The value in this field indicates the number of units that should remain in the 'From' warehouse so that inventory in this warehouse is not depleted in the replenishment process.

Determining the items to replenish: Each reservable item in the 'To' warehouse is evaluated to determine if it requires replenishing. If the Reservation freeze status of an item in either the 'To' warehouse or the 'From' warehouse is Y, the item will not be replenished.

Calculating the quantity required: If the item's on-hand quantity in the warehouse being replenished is less than the minimum amount defined for the item (from the Min qty field for the Item Warehouse), the following occurs:

• If a quantity is specified in the Reorder field for the Item Warehouse, the system requests this replenishment amount.

• If no reorder quantity is specified, the system calculates the replenishment quantity by subtracting the on-hand quantity from the maximum quantity.

Note: There can be only one replenishment request for each 'To' warehouse. If there is an open replenishment request for the warehouse, the system does not evaluate the items in the warehouse for further replenishment.

Determining where to get the inventory: Once the replenishment quantity required for the 'To' warehouse is calculated, the system evaluates the locations from which the inventory can be picked in the 'From' warehouse, and the quantities available to pick.

For example, there may not be enough inventory in the 'From' warehouse to meet the replenishment requirements for the 'To' warehouse, or the required amount may come from more than one location in the 'From' warehouse.

The system uses the following system control values in determining where to pick the inventory in both standard process and outlet transfer replenishment:

• Pickable Setting for Analyzing Replenishment Locations (G63): This field controls whether to use only pickable locations, only nonpickable locations, or both pickable and nonpickable.

• Type of Location to Search First in Warehouse Replenishment (G64): This field controls whether to search primary, secondary, or bulk locations first.

• Type of Location to Search Second in Warehouse Replenishment (G65): This field controls whether to search primary, secondary, or bulk locations second, if there is no inventory available for an item in the first type of location specified.

• Type of Location to Search Third in Warehouse Replenishment (G66): This field controls whether to search primary, secondary, or bulk locations second, if there is no inventory available for an item in the first two type of location specified.

The system does not consider inventory in temporary locations in warehouse replenishment.

Important: If all of the three "type of location" system control values are blank, the system will never create a replenishment request.

Calculating the quantity to move: The system determines the quantity available for replenishment in a location by subtracting the printed and pending transfer quantities from the on-hand quantity.

The system evaluates all appropriate locations (as specified using the system control values described above) in sequence until the replenishment amount is reached, or until there are no more locations to evaluate. The system attempts to move the inventory from a single location whenever possible. Inventory will be moved from multiple locations only when the full replenishment amount cannot be moved from a single location.

Generating the warehouse replenishment request: As the system evaluates the items to replenish and the locations in the 'From' warehouse from which to pick the inventory, a record for each transfer transaction is added to the replenishment request in an allocated (A) status.

The following system updates occur within the 'From' warehouse as the replenishment request is generated:

• The Printed quantity for each item/location where inventory will be picked increases.

• The Reserve transfer quantity for the item/warehouse increases.

Unallocating items: You have the option of unallocating any items included in a replenishment request that you do not want to fulfill. When you unallocate an item, the status of the requested item changes to U and the Printed quantity and Reserve transfer quantity fields, described above, decrease. In addition, the Requested quantity and Actual quantity for the item within the replenishment request are reset to zero. When you confirm the request, these items will not be transferred.

Confirming the transfer: When you confirm a warehouse replenishment request, the system processes "T" type inventory transactions to transfer the stock. The following system updates occur:

‘From’ Warehouse |

‘To’ Warehouse |

The On-hand quantity for each Item/Location where inventory was picked decreases |

The On-hand quantity of each item increases in the auto-restock location defined for the warehouse |

The Reserve transfer quantity for each Item/Warehouse record decreases |

|

The Printed quantity for each Item/Location record decreases |

|

In addition:

• Inventory Transaction History is written.

• The confirmed replenishment request is either retained (in a C status) or deleted from the system, depending upon how the Receive restock transfers field in the Warehouse file for the 'To' warehouse is set.

• The General Ledger Interface file is updated based on the transfer.

Purpose: The outlet transfer replenishment process obtains replenishment instructions supplied by your retail outlets, rather than information stored within CWDirect. Typically, you use the Process Outlet Transfers menu option to begin this process. The system:

• determines the replenishment requirement for items at each outlet by the Requested quantity field in the Autostock Replenishment Work file, which contains requests (purchase orders) from your outlets. Each outlet must first be identified as a warehouse in CWDirect.

• creates a batch out of each purchase order from an outlet. Each batch is distinguished by the purchase order number, date, time, and warehouse, which must be consistent within the batch.

• analyzes the inventory levels in the warehouse being used to replenish the warehouse (the 'From' warehouse) to determine the amount of inventory available to transfer.

• allocates the inventory to replenish in the locations in the 'From' warehouse where it should be picked, increasing the Reserve transfer quantity and Printed quantity fields to reflect the allocated quantity.

• requires you to process each item within the replenishment request which you will fulfill, either by scanning one unit at a time or by "processing" the entire quantity at once.

• uses the Pickable Setting for Analyzing Replenishment Locations (G63) and the Type of Location to Search First in Warehouse Replenishment (G64), Type of Location to Search Second in Warehouse Replenishment (G65), or Type of Location to Search Third in Warehouse Replenishment (G66) system control values, as described earlier in this chapter, to determine which locations in the 'From' warehouse can be used to fulfill the replenishment request.

• creates an "unallocatable" request record for each item that was requested by an outlet, but which does not currently exist in a location in the 'From' warehouse that matches the criteria specified in the System Control file.

• processes warehouse transfer inventory transactions when the replenishment request is confirmed. Inventory in the locations in the 'From' warehouse is decreased; inventory in the outlet transfer location in the 'To' warehouse is increased. Also, the Reserve transfer quantity and Printed quantity fields are decreased.

• processes any resulting postings to the General Ledger Interface file, including marking down the inventory; this markdown is calculated either by subtracting the markdown cost specified by the outlet from the standard, average, or FIFO cost (based on the setting of the Costing Method (A25) system control value), or using a percentage specified in the System Control file.

You can run the Process Outlet Transfers program whenever you receive a replenishment request from an outlet. The system will process all new requests from any outlet in the Autostock Replenishment Work file, provided they are error-free.

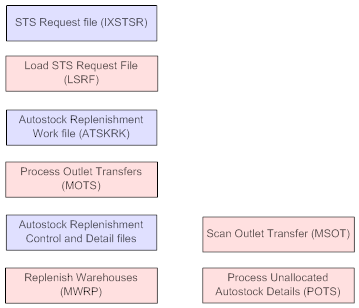

STS requests: Optionally, you can use the outlet transfers process to create replenishment requests that originate from the STS system. Load STS Request File (LSRF)takes the information from the STS request, and converts it into the Autostock Replenishment Work file. From this point forward, you use the outlet transfer process as described above.

The entire outlet transfer process is summarized in the chart below. Optional steps are indicated with dotted lines.

Warehouse file: You need to create each outlet store as a warehouse within CWDirect. However, the system does not use the Auto-restock location or Receive restock transfers fields in the Warehouse file for outlet transfer replenishment; instead, it uses locations you define using Working with Default Warehouse Locations (WWDL).

Default Warehouse Location file: You need to define the following locations within this file:

• An outlet transfer location (enter OT) to receive restock transfers in the outlet warehouse.

• An OTS unallocatable location (enter OU) in the 'From' warehouse to create a record within the request for unallocatable items (items requested by an outlet, but without an item/location record in the 'From' warehouse).

Creating the request: You select Process Outlet Transfers (MOTS) to have the system create the outlet transfer request, based on the information in the Autostock Replenishment Work file (ATSKRK). (If you are using the STS interface, you first need to load the STS Request file into the Autostock Replenishment Work file, as described above.)

If there are any errors in the replenishment request, the system generates an Autostock Feed Error Report. You must correct each record and select the Process Outlet Transfers option again. The system will not create a replenishment request until the process is error-free.

Determining where to get the inventory: The outlet transfer process works the same way as Standard Warehouse Replenishment in determining which locations in the 'From' warehouse should be used to fulfill the replenishment request.

Reviewing the request: Although you use Work with Warehouse Replenishment (MWRP) to work with both standard and outlet transfer replenishment requests, the two types of requests each follow a different process and appear differently through this menu option. In contrast to a standard replenishment request, an outlet transfer request:

• has a batch number (made up of the warehouse code of the outlet and the purchase order number)

• includes a control number for each item within the request

• may include unallocatable items (there was not record of the item in a location in the 'From' warehouse) assigned to the OU location

• may have an Actual quantity that differs from the Requested quantity for items whose quantity available in a pickable location was less than the quantity requested by the outlet

The change quantity and process options (options 2 and 9) are available only for outlet transfer requests.

Processing items: To approve any item within a request for replenishment, you must process the item before confirming the request. Only items with a P (processed) status will be transferred when the request is confirmed; items in an A (allocated) status will remain in this status. You can process the item by:

• Entering 9 next to the item at the Work with Warehouse Replenishment Detail Screen (this processes the entire Actual quantity of the item)

• Scanning the transfer one unit at a time. When you scan the first unit, the system changes the item's status to P and resets the Actual quantity to 1. With each subsequent unit, the system increases the Actual quantity by 1; you can scan any quantity of the item as long as it does not exceed the Requested quantity. The Scan Outlet Transfer Screen is available by pressing F10 at the Work with Warehouse Replenishment screen, or as a separate menu option.

Confirming the request: When you confirm the request, the system does the following for each item in a P status:

• processes an inventory transfer from the item's location in the 'From' warehouse to the default outlet transfer location in the outlet warehouse

• decreases the Reserve transfer quantity for the item in the 'From' warehouse and the Printed quantity for the item in the 'From' warehouse location

• posts any appropriate transactions to the General Ledger Interface file, using the item's markdown cost from the Autostock Replenishment Work file, if available; otherwise, the system uses the standard, average, or FIFO cost (based on the setting of the Costing method system control value) and the Markdown Cost Percentage for Liquidation (E20) from the System Control file, posting the difference to the Markdown Cost General Ledger Number (E21) also defined in the System Control file

The status of the request changes to C. However, any items in A or U status within the request will remain in that status. Processed lines will change to C status if the Receive restock transfers field for the outlet warehouse is set to Y; otherwise, these lines will change to X status (however, you cannot use the place stock option in the Replenish Warehouses menu option for outlet transfers).

The system does not delete the request automatically. You need to clear the related files yourself through a method outside of CWDirect.

| Part I: Replenish Warehouses | Contents | SCVs | Search | Glossary | Reports | XML | Index | Chapter 59: Work with Warehouse Replenishment (MWRP) |

WH10_01 CWDirect 18.0 August 2015 OTN