Setting Up PeopleSoft Inventory Structure Tables

To define item storage codes, use the Item Storage Codes (STORAGE_CODES) component. To define storage location types, use the Storage Location Types (STOR_LOC_TYPE) component. To define backlog reason codes, use the Backlog Reason Code (BACKLOG_RSN_INV) component. To define item packaging codes, use the Item Packaging Codes (PACKAGING_CODES) component. To define quarantine codes, use the Inventory Status Types (QUARANTINE_CODES) component. To define storage rules, use the Storage Rules (STOR_INSTRUCTIONS) component.

PeopleSoft Inventory structure tables store inventory information and facilitate enterprise-wide management and reporting for inventory and materials management activities. You must set up these core tables before you can perform tasks such as putting away items or fulfilling stock requests. Enter at least one complete set of tables, then share them across business units as needed.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

STOR_LOC_TYPE_INV |

Define the types of storage locations that you use. |

|

|

Inventory Status Types Page |

QUARANT_CODE_INV |

To create inventory status types, use the Inventory Status Types component. Define reasons for changing the status of stored items to Hold, Rejected, or Restricted on the Inventory Status and Material Storage Locations pages.

|

|

Item Storage Codes Page |

STORAGE_CODE_INV |

To create item storage codes, use the Item Storage Codes component. Establish storage codes to be used for informational purposes during manual staging for putaway.

|

|

Return Type Codes Page |

RMA_RETURN_TYPE |

Define codes for grouping actions triggered during material returns. |

|

PACKAGING_CODE_INV |

Establish standard codes for packaging. |

|

|

BACKLOG_RSN_INV |

Establish codes representing reasons for delayed shipments. |

|

|

HOLD_CD |

Establish codes indicating why orders are on hold. |

|

|

TRANS_UNIT_INV |

Define default interunit transfer attributes for a business unit. |

|

|

Storage Rules Page |

STOR_INSTRUCT_INV |

Establish standard codes to represent special storage requirements for an item.

|

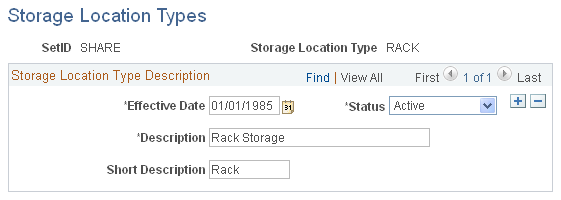

Use the Storage Location Types page (STOR_LOC_TYPE_INV) to define the types of storage locations that you use.

Navigation:

This example illustrates the fields and controls on the Storage Location Types page. You can find definitions for the fields and controls later on this page.

Assign a code to each type of material storage location in your enterprise. Examples of storage location types include standard racking, liquid container storage, and tote storage.

Storage location type codes appear on the Material Storage Locations page, the Review Material Storage Loc page, and the Storage Locations report.

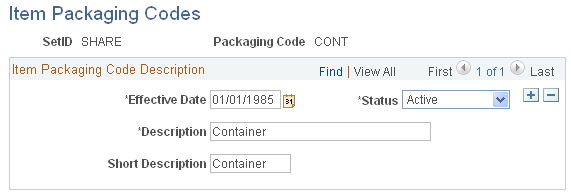

Use the Item Packaging Codes page (PACKAGING_CODE_INV) to establish standard codes for packaging.

Navigation:

This example illustrates the fields and controls on the Item Packaging Codes page. You can find definitions for the fields and controls later on this page.

You can assign packaging codes to items during material stock request or express issue creation. The Packing component uses these codes to provide packing instructions for shipment.

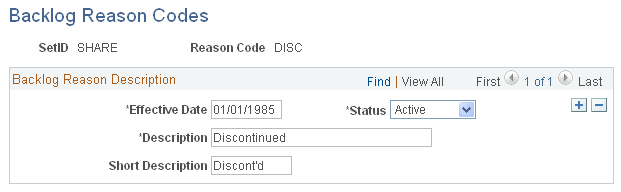

Use the Backlog Reason Codes page (BACKLOG_RSN_INV) to establish codes representing reasons for delayed shipments.

Navigation:

This example illustrates the fields and controls on the Backlog Reason Codes page. You can find definitions for the fields and controls later on this page.

You can assign these codes to specific demand lines on the Shipping Backlogs page.

To create hold codes, use the Hold Codes component.

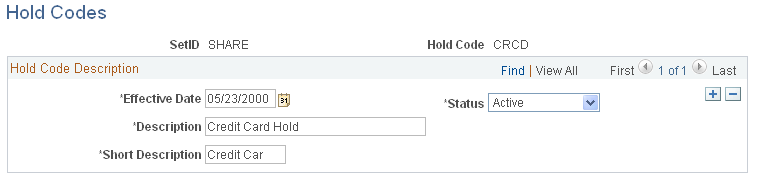

Use the Hold Codes page (HOLD_CD) to establish codes indicating why orders are on hold.

Navigation:

This example illustrates the fields and controls on the Hold Codes page. You can find definitions for the fields and controls later on this page.

Use this page to define hold codes to be used during your business processes. Hold codes are used when:

Putting demand lines on hold on the Cancel/Hold Stock Request page.

Activating the Put on Hold option on the Inventory Definition - Business Unit Options: Shipping Options page.

Automatically applied by the system during Financial Sanctions Screening functions (FSS).

Using this page, you can define one or more hold codes to be used by the Financial Sanctions Screening function. For Inventory, only one hold code can be used automatically by the FSS process. Define the code here, and then add the default hold code to the Installation Options - Inventory page to enable the Screen for Denied Parties Process (SCM_FSS) to review material stock requests (MSRs) and automatically apply the hold code to any MSR that fails to pass screening. A hold code prevents an MSR from shipping. You can manually add or remove a hold code from an MSR using the Cancel/Hold Stock Requests page.