Integrating with a Manufacturing Execution System

You can integrate to a Manufacturing Execution System (MES) to enable the optimization of production activities from production order launch to completion of finished goods. MES functions include:

Resource Allocation and Status

Operations/Detail Scheduling

Dispatching Production Units

Document Control

Data Collection/Acquisition

Labor Management

Quality Management

Process Management

Maintenance Management

Product Tracking and Genealogy

Performance Analysis

Using PeopleSoft Manufacturing's integration, you can:

Communicate production orders and production schedules from PeopleSoft to the MES using the Production Order Update EIP.

Communicate item revision information from PeopleSoft to the MES using the Item Master EIP.

Send operation and order completion and scrap information from the MES to PeopleSoft using the Completions EIP.

Send component item usage from the MES to PeopleSoft using the Edit/Issue EIP.

Analyze production performance in either PeopleSoft or the MES. If you are looking for more detailed operational information, you'll want to use the MES to gather this information.

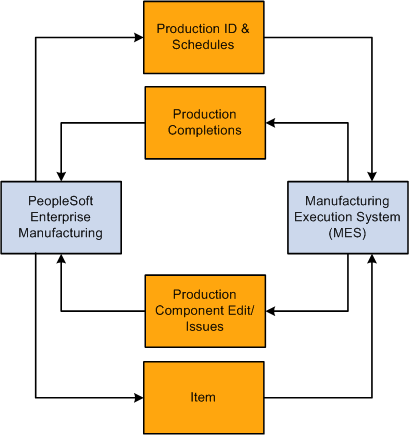

This diagram illustrates the transfer of data between PeopleSoft Manufacturing and any MES, including the transfer of production IDs, production schedules, production completions, production component edits and issues, and item data:

You'll continue to use PeopleSoft Manufacturing for planning, material movement into WIP, validation of completion data, and production costing functions. PeopleSoft is the system of record for setup information, including item masters, bills of material, routings, and creating production orders.

When you add or modify production with a status of Firmed or greater, component lists, operation lists, and output lists, the system creates a publish message for the MES to pick up. The system also creates a publish message when changes are made using background programs.

You manage errors for the Completions and Edit/Issues transactions using Transaction Maintenance.

You use the Publish Outbound Transactions page to initiate the outbound publish process for the Production Order Update EIP and the Item Master outbound EIP.

Using the Item Master Transaction

You can publish item revision information to the Manufacturing Execution System using the Item Master outbound EIP. This is an outbound, asynchronous message. When you create or modify a revision, approve a revision-controlled item, or add business unit attributes to a revision-controlled item, the system publishes an item revision message to the Manufacturing Execution System.

Using the Production ID/Production Schedule Manufacturing Execution System Transaction

Use the Production Order Update EIP to export production ID or production schedule changes to an external system. This is an outbound, asynchronous message.

Using the Completions Manufacturing Execution System Transaction

Use the Production Completions EIP to import information into PeopleSoft Manufacturing. This is an inbound, asynchronous message.

See Understanding the Process of Recording Completions and Scrap Using Electronic Data Collection.

Using the Edit/Issues Manufacturing Execution System Transaction

Use the Production Order Issue EIP to import edit or issue component information from a third-party system. This is an inbound, asynchronous message.

By using PeopleSoft Manufacturing, you can send item, revision, and manufacturing bill of material (BOM) information using product life cycle management applications.