Integrate Oracle Fusion Cloud Manufacturing with Oracle IoT Production Monitoring Cloud Service

You can import work orders from Oracle Fusion Cloud Manufacturing into Oracle Internet of Things (IoT) Production Monitoring Cloud Service. The application automatically updates the work order status and produced quantities in Oracle Fusion Cloud Manufacturing based on updates from the machine or operator.

In Oracle Fusion Cloud Manufacturing, a work order refers to a document that conveys the authority for the production of a specific product. It contains information about what, how, how many, and when to manufacture a product. The product item, work definition details, operations, resources, components, quantities, and dates are specified in the work order.

When configuring integration with Oracle Fusion Cloud Manufacturing, you can choose to create one-to-one mappings between the manufacturing organizations and your IoT organizations. If you choose one-to-one, the IoT server creates a separate IoT organization for each manufacturing organization that you enable in Oracle Fusion Cloud Manufacturing. If you choose many-to-one, then entities from each manufacturing organization that you enable in Oracle Fusion Cloud Manufacturing are imported into the selected organization in Oracle IoT Production Monitoring Cloud Service.

Oracle Fusion Cloud Manufacturing automatically synchronizes the factory entities with IoT for all manufacturing organizations that you enable in Oracle Fusion Cloud Manufacturing. Oracle IoT Production Monitoring Cloud Service no longer needs to pull these entities at regular intervals. The pull settings are deprecated and may be removed in a future release.

You can edit the work orders to assign resource instances (machines and operators) to the work orders in Oracle IoT Production Monitoring Cloud Service. These resource instances are then used for production and completion of the work order. Oracle IoT Production Monitoring Cloud Service automatically updates the work order status and produced quantities in Oracle Fusion Cloud Manufacturing based on updates from the machine or operator.

Add the IoT Application Integration Entry in Oracle Fusion Cloud Manufacturing

To begin integration with Oracle IoT Production Monitoring Cloud, add an application integration entry in Oracle Fusion Cloud Manufacturing with details to connect to your IoT application.

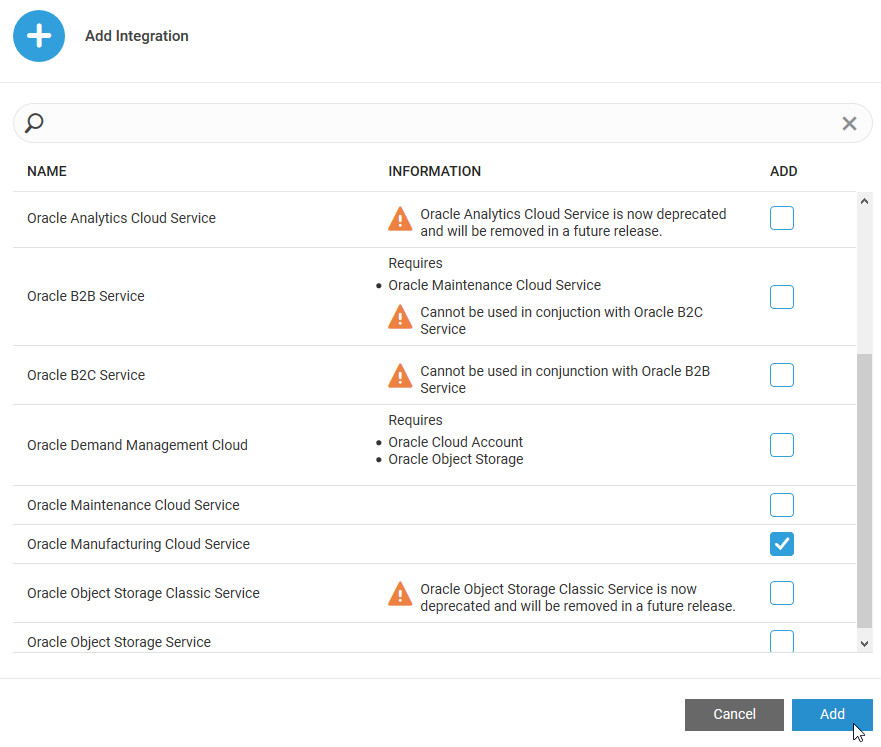

Add an Oracle Fusion Cloud Manufacturing Integration

Use the Integrations page in Oracle Internet of Things (IoT) Production Monitoring Cloud Service to enable integration with Oracle Fusion Cloud Manufacturing.

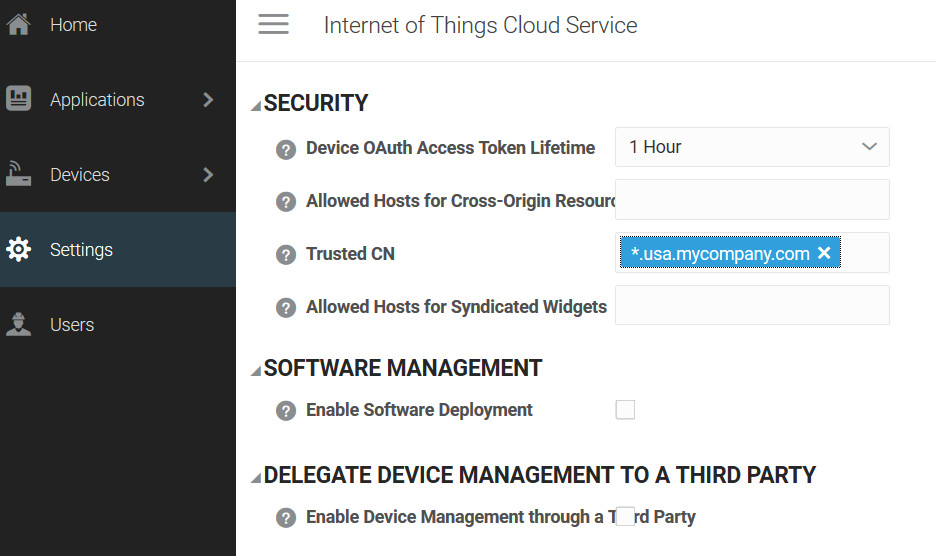

Before you configure Oracle Fusion Cloud Manufacturing integration, make sure your Oracle Fusion Cloud Manufacturing host is trusted by your Oracle Internet of Things Intelligent Applications Cloud domain.

Host names with .oraclecloud.com and .oraclecloudapps.com suffixes are always allowed. If your Oracle Fusion Cloud

Manufacturing domain name is different, then add the domain as a trusted CN in the Oracle Internet of Things Intelligent

Applications Cloud management console. To do this, add *.YourDomain.com under Trusted CN in the Settings page.

You can access your Oracle Internet of Things Intelligent Applications Cloud management console at the following URL:

https://hostname/ui

Here, hostname is the host name of your Oracle Internet of Things Intelligent

Applications Cloud instance.

Enable and Configure the Oracle Fusion Cloud Manufacturing Integration

To start using Oracle Fusion Cloud Manufacturing integration, enable and configure the integration for Oracle Manufacturing Cloud Service on the Integrations page.

Enable a Manufacturing Organization for IoT Synchronization

When you enable a manufacturing organization to sync with IoT, Oracle Fusion Cloud Manufacturing creates the corresponding factory, along with its constituent entities, in Oracle IoT Production Monitoring Cloud Service. All subsequent updates to the factory are automatically pushed to Oracle IoT Production Monitoring Cloud Service.

Understand Data Exchange with Oracle Fusion Cloud Manufacturing

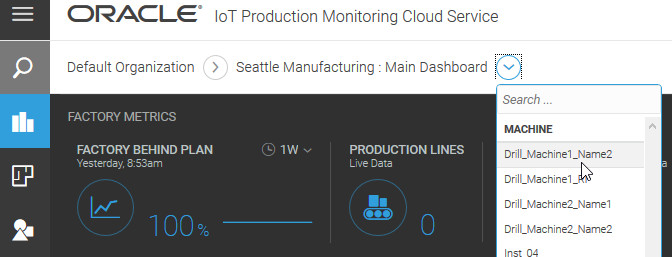

After you configure the integration and enable one or more manufacturing organizations in Oracle Fusion Cloud Manufacturing to sync with IoT, Oracle Fusion Cloud Manufacturing automatically syncs the factory entities with IoT for the selected manufacturing organizations.

Oracle IoT Production Monitoring Cloud Service creates a factory corresponding to each manufacturing organization that is imported. The factory name is the same as the name of the manufacturing organization being imported.

If you choose one-to-one mapping, the IoT server creates a separate IoT organization for each manufacturing organization that you enable in Oracle Fusion Cloud Manufacturing. If you choose many-to-one mapping, then entities from each manufacturing organization that you enable in Oracle Fusion Cloud Manufacturing are imported into the selected organization in Oracle IoT Production Monitoring Cloud Service.

Data is imported into Oracle IoT Production Monitoring Cloud Service from Oracle Fusion Cloud Manufacturing. During the import process, Oracle IoT Production Monitoring Cloud Service converts Oracle Fusion Cloud Manufacturing resources to the following Oracle IoT Production Monitoring Cloud Service entities:

| Oracle Fusion Cloud Manufacturing Resource | Oracle IoT Production Monitoring Cloud Service Entity |

|---|---|

| Manufacturing organization | Factory |

| Items | Products and product data |

| Work orders | Work orders and routing data |

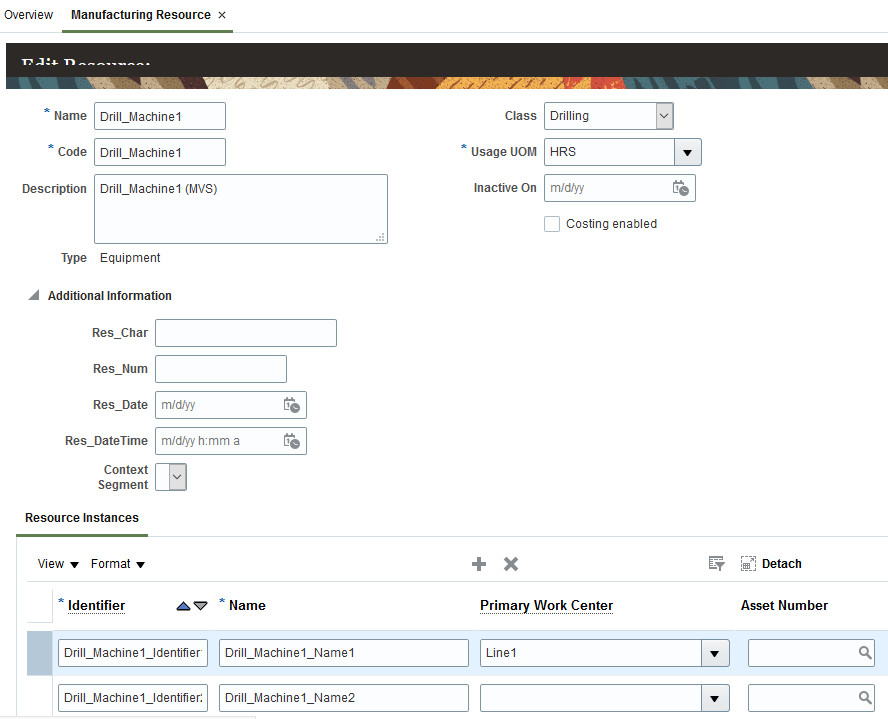

| Resources and resource instances | Machine types and machines, operator types and operators |

The machine types and operator types imported into Oracle IoT Production Monitoring Cloud Service have their respective Oracle Fusion Cloud Manufacturing organization codes suffixed to their names. So, if you have similarly named resources in two or more Oracle Fusion Cloud Manufacturing organizations, you can distinguish between these resources in Oracle IoT Production Monitoring Cloud Service using the org suffix in their names.

Edit the imported entities, as required in Oracle IoT Production Monitoring Cloud Service. For example, you can edit the factories to add location information.

Oracle IoT Production Monitoring Cloud Service automatically updates the work order status and produced quantities in Oracle Fusion Cloud Manufacturing based on updates from the machine or operator. The outbound sync frequency determines how often production output updates are synchronized with Oracle Fusion Cloud Manufacturing.

Support for Process Manufacturing Work Orders

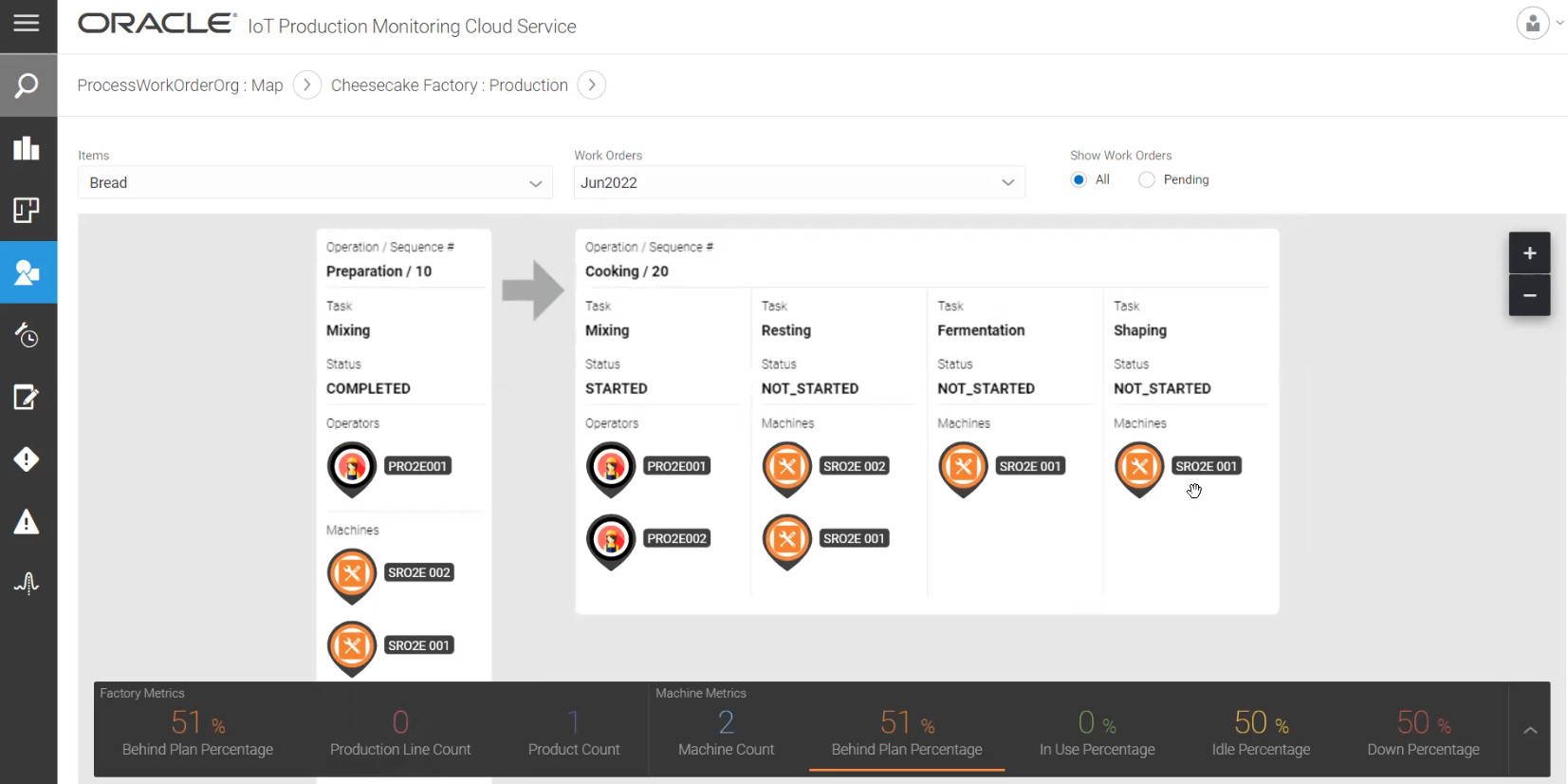

Production Monitoring supports process manufacturing work orders in addition to discrete manufacturing work orders. Use the factory production view to see the various stages and operations for a process work order. The work order view, together with associated factory and machine metrics, is available for the primary product.

The product routing view is available if the product routing and production lines have been created. The following example shows the Production tab for a factory that uses process manufacturing work orders. You can select the product and work order to view the product routing information.

For each operation in the process work order, you can see the various serial and parallel routing tasks, together with the operator and machine resources associated with each routing task.

You can use both system and custom metrics with process work orders. System metrics, such as the number of in-process and pending work orders are available by default. You may also wish to create custom metrics that use work order data, such as batch quantity or reject/scrap data.

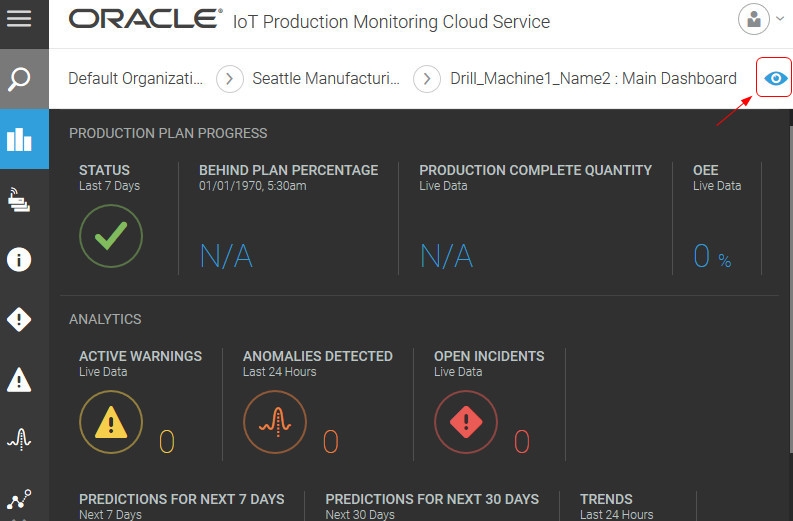

View the Manufacturing Resource for an Imported Machine

Machines imported in Oracle IoT Production Monitoring Cloud Service can link back to the corresponding manufacturing resource in Oracle Fusion Cloud Manufacturing.

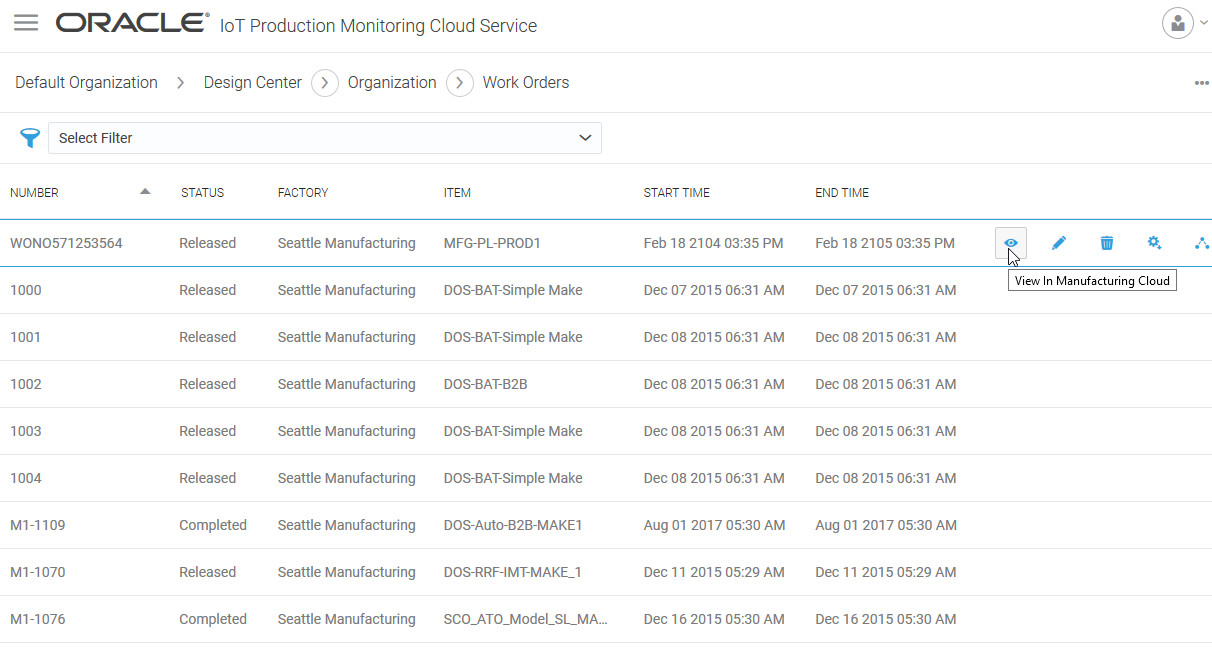

Access the Work Orders

The work orders from Oracle Fusion Cloud Manufacturing automatically appear in Oracle Internet of Things (IoT) Production Monitoring Cloud Service.

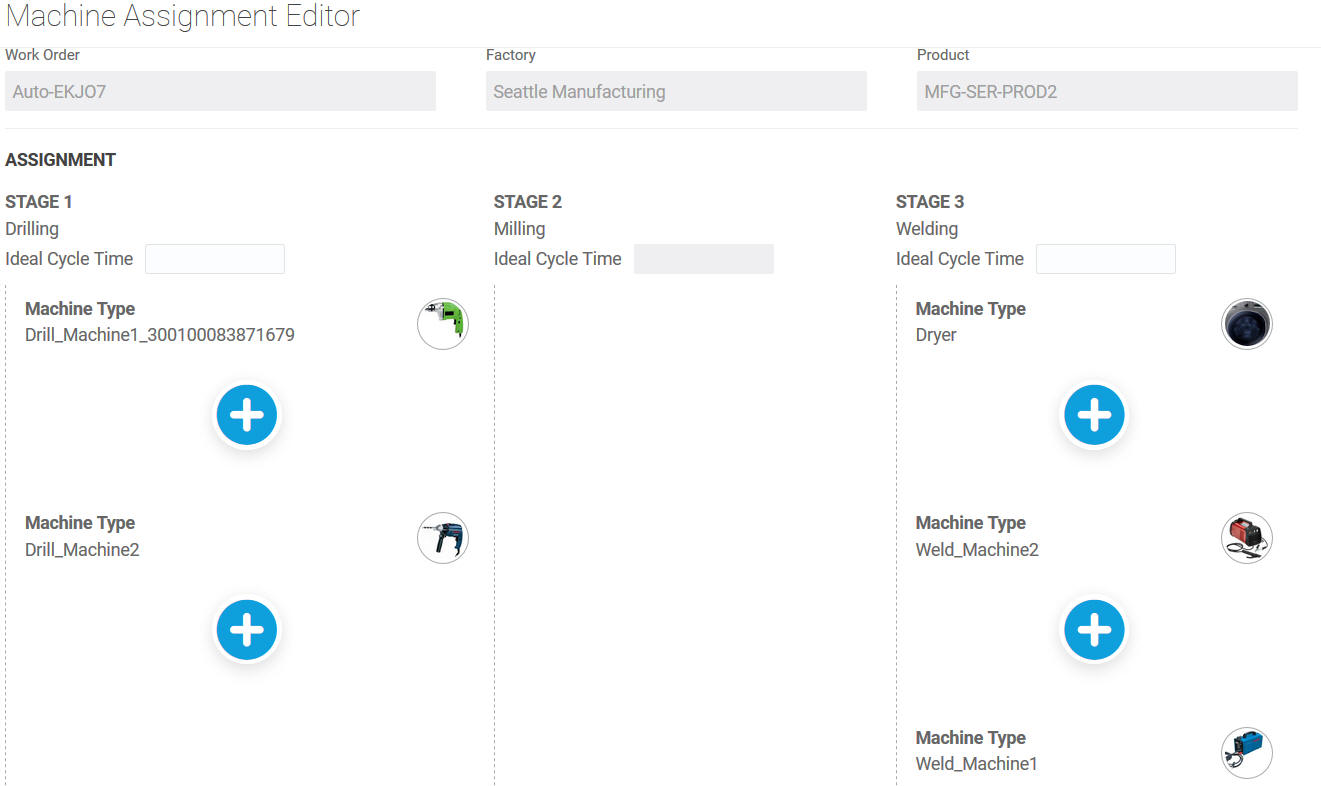

Add Machines and Operators to Work Orders

You can edit the work orders to assign machines and operators to the work orders in Oracle Internet of Things (IoT) Production Monitoring Cloud Service.

If your work order data contains operator type information, then you can also assign operators in Oracle IoT Production Monitoring Cloud Service

Assign Machines and Operators to Similar Work Orders

You can use a completed work order’s data to assign the same machines and operators to other, similar work orders if these work orders belong to the same factory and product, and use the same routing tasks.

Assign Machines from Another Work Order

You can assign machines to a work order by copying data from another, similar work order if the two work orders belong to the same factory and product, and use the same routing tasks.

Download, Edit, and Upload Work Orders

You can manually download work order data to your local disk, edit the work order resource assignments, and upload work orders back to Oracle IoT Production Monitoring Cloud Service.

Download Work Orders

To download all work orders:

-

To download all work orders listed on the Work Orders page, click Menu

and select Download All.

and select Download All.

-

Save the

csv(comma-separated value) file to the desired location on your hard disk or storage device.

To download a specific work order:

-

On the Work Orders page, click Download

against the work order row.

against the work order row.

-

Save the

csv(comma-separated value) file to the desired location on your hard disk or storage device.

Edit Work Orders

You can edit the work order csv file downloaded from Oracle IoT Production Monitoring

Cloud Service to update the machine and operator assignments:

-

Open the

csvfile that you downloaded from Oracle IoT Production Monitoring Cloud Service -

Edit the rows to update the machine and operator assignments. For example, you can choose to add resource IDs to each row.

So, if a data row looks like the following:

# Start Time, End Time, Work Order ID, Work Order Number, Work Order Status, Routing Task ID, Resource ID, Assigned Units, Ideal Cycle Time 2017-10-01T13:05:20Z, 2017-12-11T03:32:00Z, 300100084274083, MFG1-1029, ORA_UNRELEASED, FD631293-3F86-4179-8256-D18EEDBDF797, 300100073217818, 1, 18000000It may look like the following after adding a machine ID:

# Start Time, End Time, Work Order ID, Work Order Number, Work Order Status, Routing Task ID, Resource ID, Assigned Units, Ideal Cycle Time, Machine ID 2017-10-01T13:05:20Z, 2017-12-11T03:32:00Z, 300100084274083, MFG1-1029, ORA_UNRELEASED, FD631293-3F86-4179-8256-D18EEDBDF797, 300100073217818, 1, 18000000, Machine550_1

Upload Work Orders

To upload a csv work order file back to Oracle IoT Production Monitoring

Cloud Service:

On the Work Orders page, click Menu ![]() , select Upload CSV File, and then select the file to upload.

, select Upload CSV File, and then select the file to upload.

Delete Work Orders

You may wish to delete work orders, for example, to clean up a previously configured Oracle Fusion Cloud Manufacturing integration.

To delete all work orders:

-

To delete all work orders listed on the Work Orders page, click Menu

and select Delete All.

and select Delete All.

-

Click Delete to confirm.

To delete a specific work order:

-

On the Work Orders page, click Delete

against the work order row.

against the work order row.

-

Click Delete to confirm.

Create Production Lines

As Oracle Fusion Cloud Manufacturing doesn't use production lines, you can choose to add the machines to a production line in Oracle Internet of Things (IoT) Production Monitoring Cloud Service.

View the Work Orders in Factory View

After you add work orders in Oracle Internet of Things (IoT) Production Monitoring Cloud Service and create the production line, you can view work orders in the Factory view.

Verify Work Order Status and Produced Quantities

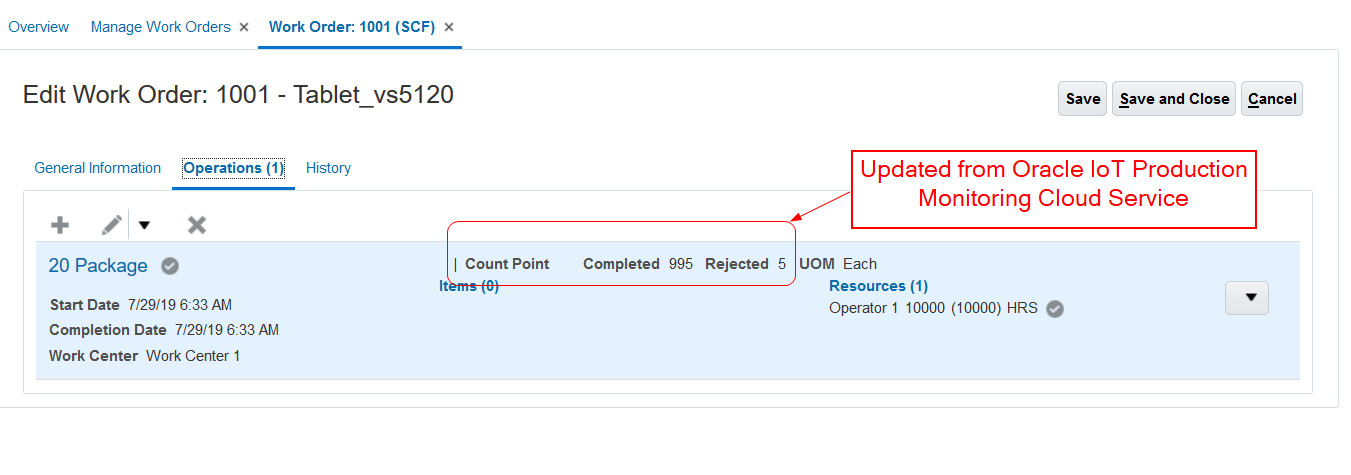

Oracle IoT Production Monitoring Cloud Service automatically updates the work order status and produced quantities in Oracle Fusion Cloud Manufacturing based on updates from the machine or operator.

Note:

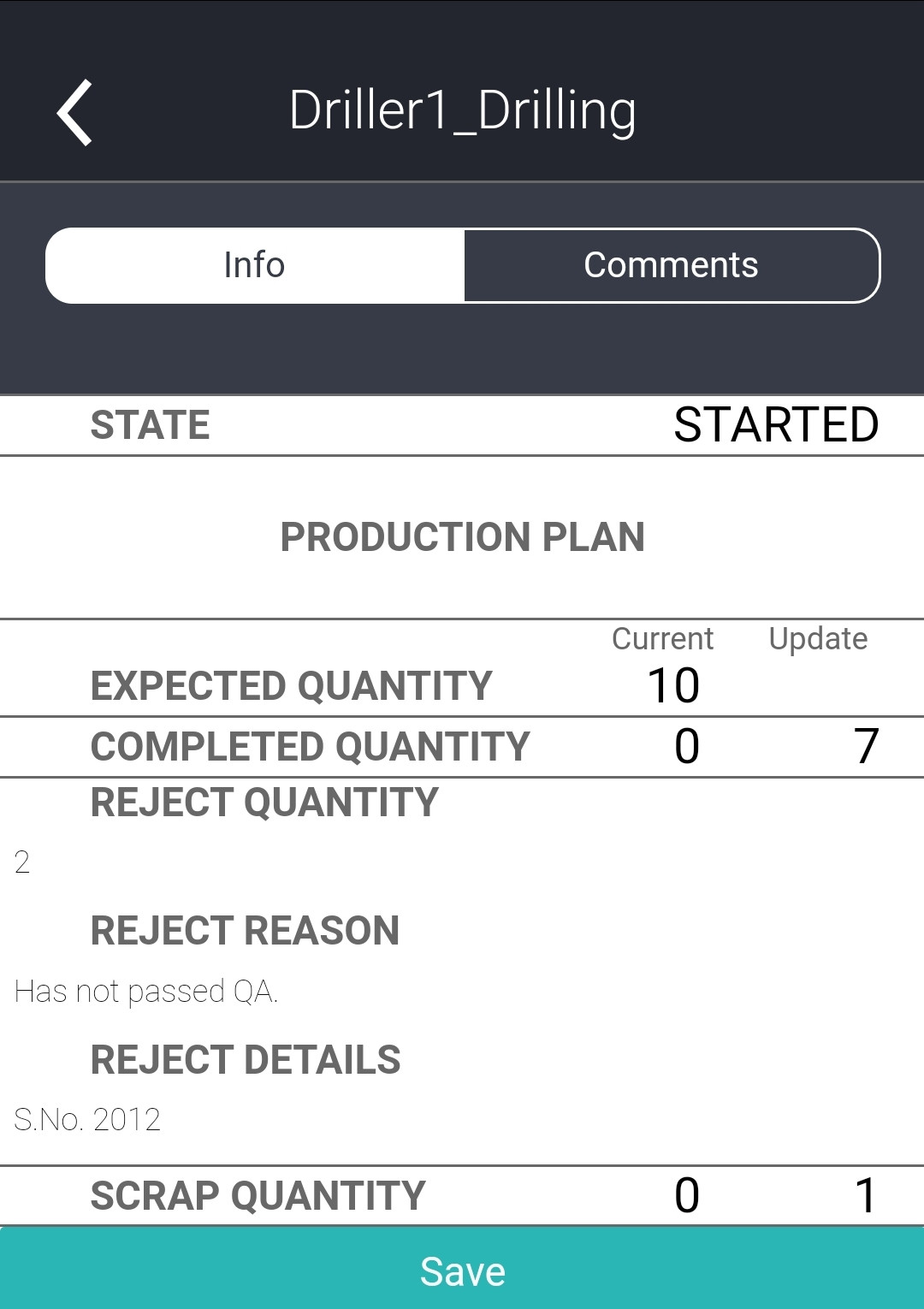

If you were to directly update the quantities or operation status in Oracle Fusion Cloud Manufacturing, then these are not synced back with Oracle IoT Production Monitoring Cloud Service.In the following example, a user with Operator privilege uses the mobile app to start a production routing task and set the output quantities including reject and scrap quantities.

The work order status and production output quantities are sync'd to Oracle Fusion Cloud Manufacturing at periodic intervals.

If bad quantities (reject and scrap quantities) are produced during an intermediate resource instance completion step, they are synced with Oracle Fusion Cloud Manufacturing without waiting for the last resource instance completion step. Completed quantities are sent only from the last stage of each operation.

If you are using the Reject Reason and Scrap Reason fields, these must match one of the user-defined reason codes in Oracle Fusion Cloud Manufacturing. You can check or add the reason codes using the Manage Production Lookups task under the Setup and Maintenance area in Oracle Fusion Cloud Manufacturing.

The Reject Details and Scrap Details fields can contain free-form text.

Note:

In Oracle Fusion Cloud Manufacturing, the descriptive flexfield (DFF) Work Order Operation Transactions (OperTxn_Char) has a 10 character length, by default. If your operator names are longer, you can set this length to the desired value in Oracle Fusion Cloud

Manufacturing. Any operator names longer than the OperTxn_Char character length in Oracle Fusion Cloud

Manufacturing are automatically truncated to the OperTxn_Char character length.

If the OperTxn_Char DFF is not configured in Oracle Fusion Cloud

Manufacturing, then Oracle IoT Production Monitoring

Cloud Service does not send the operator name with the operation transaction details.

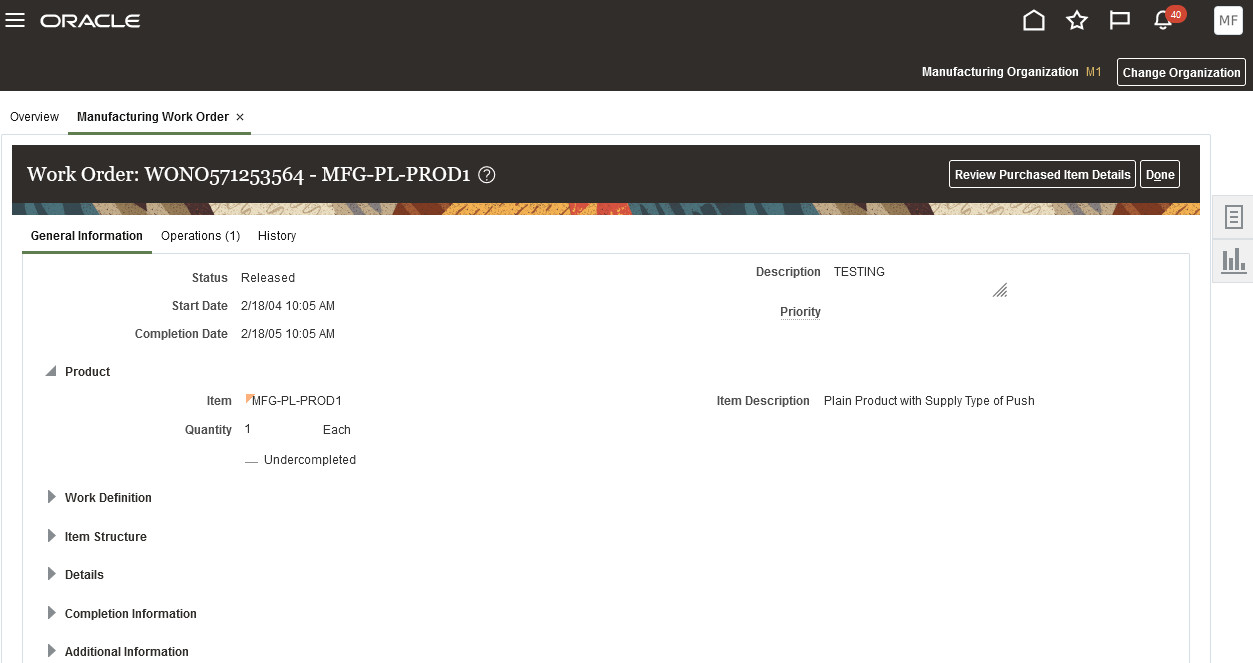

In Oracle Fusion Cloud Manufacturing, navigate to Supply Chain Execution > Work Execution and select Manage Work Orders from the Tasks menu to search your work order.

The following image shows the Operations tab for a work order in Oracle Fusion Cloud

Manufacturing, which shows the last known count of completed quantities and bad quantities.

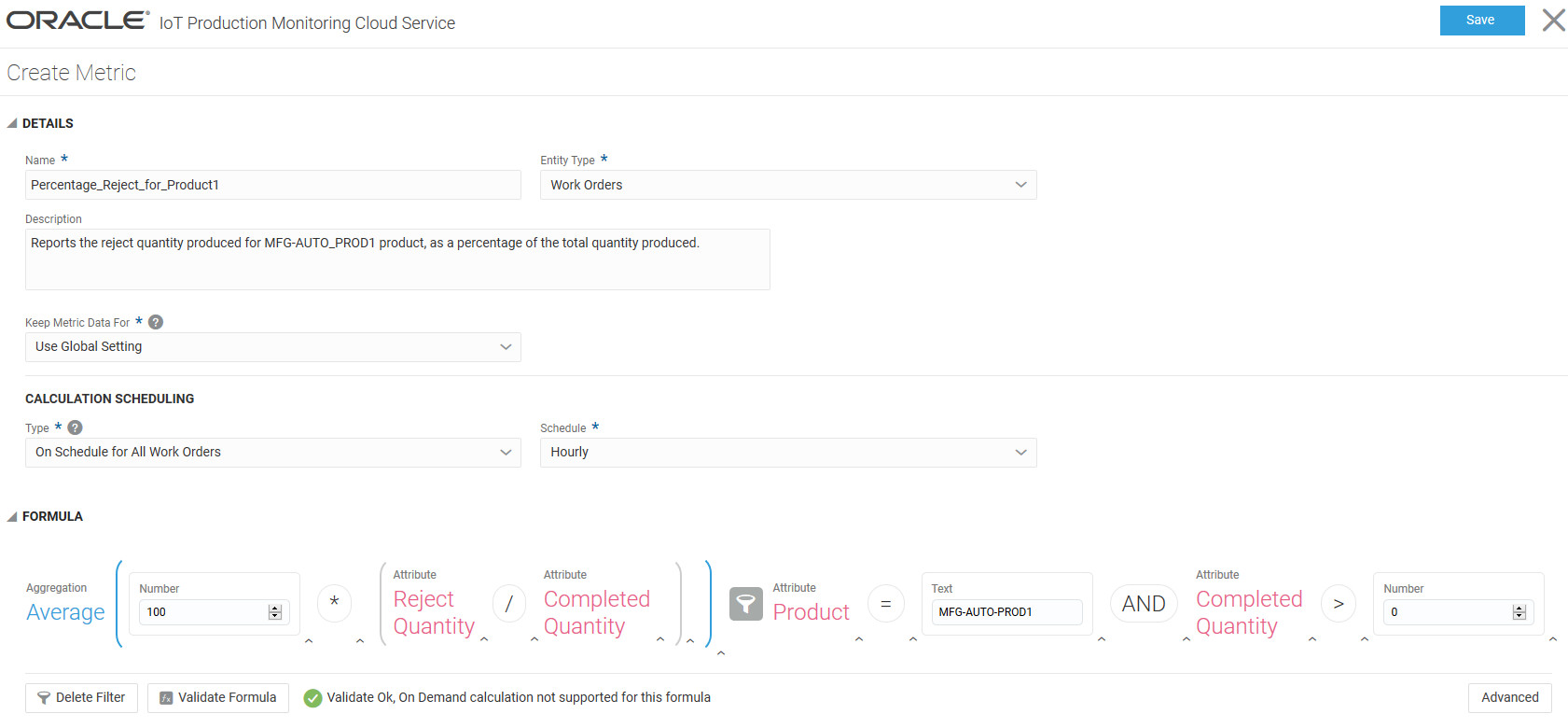

Use Work Order Data in Metrics and Rules

You can create custom metrics for your organization using data from your work order attributes, such as actualStartTime, actualEndTime, Completed Quantity, Reject Quantity and Scrap Quantity.

For example, you can create a metric to report the reject quantity produced for a product, as a percentage of the total quantity produced.

Where condition checks to ensure that the work order has completed. The resultant time difference is returned in milliseconds. SELECT AVG('actualEndTime'-'plannedEndTime') FROM 'workOrders' WHERE 'actualEndTime'>0See Define Your Own Metrics for more information on creating custom metrics.

Like other custom metrics, you can add work-order based metrics to your main dashboard, or custom dashboards.

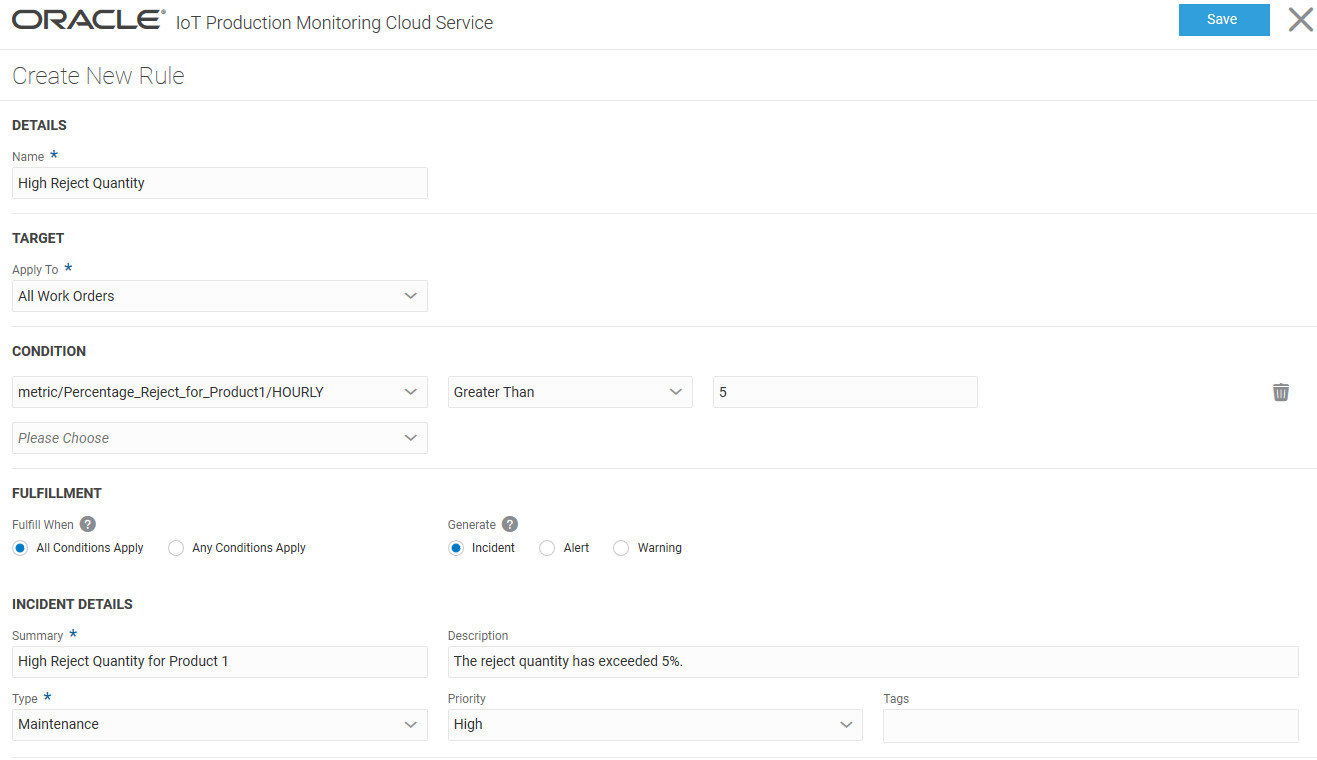

Create rules based on your work-order based metrics to trigger alerts. For example, you can create a rule to generate an incident if the reject percentage exceeds 5%.

See Define Rules to Trigger Incidents for more information on creating rules.

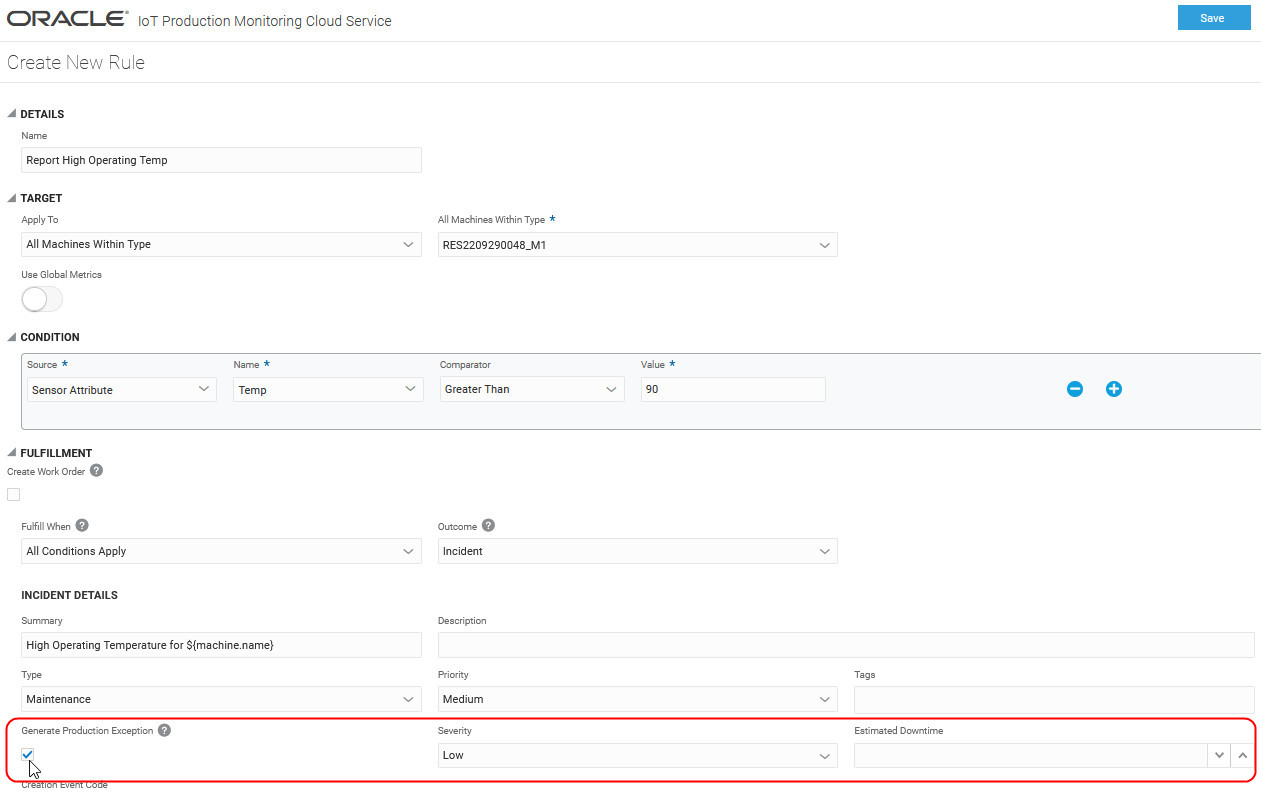

Production Exceptions for Machine Incidents

Production Monitoring can notify Manufacturing Cloud about machine incidents that affect the completion of a work order. The notifications can include additional details, such as the incident severity and estimated downtime.

You can configure rules to create production exceptions in Manufacturing Cloud corresponding to incidents in Production Monitoring. The following image shows an example of a rule editor that is used to create a production exception in Manufacturing.

When you subsequently resolve or withdraw an incident in Production Monitoring, IoT automatically closes the production exception in Manufacturing Cloud. Alternatively, if you close the production exception in Manufacturing Cloud, the incident is automatically resolved in Production Monitoring. If you also happen to have a maintenance work order for the same incident in Maintenance Cloud, then the incident status is updated to Work in Progress in Production Monitoring.

Using Oracle Fusion Cloud Manufacturing Together with Oracle Fusion Cloud Maintenance

You can map your Oracle Fusion Cloud Manufacturing machines as maintainable assets in Oracle Fusion Cloud Maintenance.

In Oracle Fusion Cloud Manufacturing, map the resource instances to asset numbers of the corresponding assets in Oracle Fusion Cloud Maintenance.

When an incident is created against an imported machine in Oracle IoT Production Monitoring Cloud Service, the incident automatically translates into a work order for the corresponding asset in Oracle Fusion Cloud Maintenance.

When using both Oracle Fusion Cloud Manufacturing and Oracle Fusion Cloud Maintenance, import machines from Oracle Fusion Cloud Manufacturing. Use the Oracle Fusion Cloud Maintenance integration to create automatic maintenance work orders for machines imported from Oracle Fusion Cloud Manufacturing.

Description of the illustration integration-mnt-mfg-cloud.eps

Configure and Use the Three-Way Integration

Set the asset numbers for your resource instances (machines) in Oracle Fusion Cloud Manufacturing, so as to map them to their corresponding asset numbers in Oracle Fusion Cloud Maintenance.

Note:

If you have additional assets in Oracle Fusion Cloud Maintenance that do not have corresponding machines in Oracle Fusion Cloud Manufacturing, you can manually import these assets into Oracle IoT Production Monitoring Cloud Service. See Import Machines from Oracle Fusion Cloud Maintenance for more information on directly importing Oracle Fusion Cloud Maintenance assets.Using Predictions and Anomalies in Supply Planning

Oracle Supply Chain Planning can make use of the predictions and anomalies generated for your manufacturing resource instances to help with Supply Planning.

The Planning Advisor interface in Supply Planning lets you plan your shop floor resources using downtime event prediction inputs from Production Monitoring. Production Monitoring provides real-time production planning capabilities by helping you understand the impact to your order due date commitments, and enabling you to re-adjust the plan. You can respond to failures before they happen and take mitigating actions, such as offloading to alternate resources.

For detailed information on this feature, including prerequisites, configuration steps, and usage, please refer to the Using Supply Planning guide:

- Using Supply Planning: Downtime Alerts for Resources in Supply Plan

- Demo Video

Frequently Asked Questions on Integration Issues

Commonly seen issues with Oracle Fusion Cloud Manufacturing integration relate to work order updates, inbound sync, and outbound sync related items.

My changes to work order resource assignments in Oracle Fusion Cloud Manufacturing are not being imported into Oracle IoT Production Monitoring Cloud Service.

In certain scenarios, such as resource assignment changes in Oracle Fusion Cloud Manufacturing for work orders already imported into Oracle IoT Production Monitoring Cloud Service, you may not see the updates reflect back in Oracle IoT Production Monitoring Cloud Service. Use the following workaround for such scenarios:

When you make work order updates in Oracle Fusion Cloud Manufacturing, update one of the work order header parameters, such as the work order Description field.

My changes to resource assignments for imported work orders in Oracle IoT Production Monitoring Cloud Service are not synced back to Oracle Fusion Cloud Manufacturing

You can change the resource assignments for your imported work orders in Oracle IoT Production Monitoring Cloud Service. However, these changes are not exported back to Oracle Fusion Cloud Manufacturing.

I made some resource assignments for imported work orders in Oracle IoT Production Monitoring Cloud Service, but then subsequently modified the resource assignments in Oracle Fusion Cloud Manufacturing. Can these changes be reconciled?

The next inbound sync from Oracle Fusion Cloud Manufacturing to Oracle IoT Production Monitoring Cloud Service overrides the assignments you made in Oracle IoT Production Monitoring Cloud Service. Oracle Fusion Cloud Manufacturing is the source of truth for these resource assignments.

If I update production output details directly in Oracle Fusion Cloud Manufacturing, are these imported back to Oracle IoT Production Monitoring Cloud Service?

Actual production details are updated from Oracle IoT Production Monitoring Cloud Service to Oracle Fusion Cloud Manufacturing. We currently do not support importing actual production details from Oracle Fusion Cloud Manufacturing into Oracle IoT Production Monitoring Cloud Service.

If I update a work order operation status directly in Oracle Fusion Cloud Manufacturing, is the operation status updated in Oracle IoT Production Monitoring Cloud Service?

No. Work order operation statuses are not imported from Oracle Fusion Cloud Manufacturing into Oracle IoT Production Monitoring Cloud Service.

When an operator updates the work order operation in Oracle IoT Production Monitoring Cloud Service using the mobile application, the changes are synced with Oracle Fusion Cloud Manufacturing. Alternately, a machine can also update the work order operation with a device message, and the changes are synced with Oracle Fusion Cloud Manufacturing.Oracle IoT Production Monitoring Cloud Service automatically changes the status of the work order operation to Started when the first production output is sent for an operation stage.

I am running into problems when updating output quantities in Oracle IoT Production Monitoring Cloud Service along with reject and scrap quantities.

If you are using the Reject Reason and Scrap Reason fields, these must match one of the user-defined reason codes in Oracle Fusion Cloud Manufacturing. You can check or add the reason codes using the Manage Production Lookups task under the Setup and Maintenance area in Oracle Fusion Cloud Manufacturing.

The Reject Details and Scrap Details fields can contain free-form text.

See Verify Work Order Status and Produced Quantities for more information about updating output quantities.

How do parallel resources work in a work order?

If a work order routing stage has two or more parallel resources, then Oracle IoT Production Monitoring Cloud Service exports actual production details only from the resource instance marked as principal.

Currently, Oracle Fusion Cloud Manufacturing does not have a flag to indicate whether the resources are working independently or in parallel. To avoid duplication of actual quantities, Oracle IoT Production Monitoring Cloud Service assumes that the parallel resources work together and produce the same set of products.

The work order status in Oracle IoT Production Monitoring Cloud Service is not updated automatically after production begins.

After production begins, Oracle IoT Production Monitoring Cloud Service automatically changes the work order operation status to Started. Oracle IoT Production Monitoring Cloud Service does not, however, update the work order status, say from Unreleased to Released.

If I update work order status to complete, does Oracle IoT Production Monitoring Cloud Service automatically update the actual quantities to match the expected quantity?

No. Actual quantities are updated by a machine or operator.

The output quantities are updated in Oracle Fusion Cloud Manufacturing, but the operator name is missing.

If the OperTxn_Char DFF is not configured in Oracle Fusion Cloud

Manufacturing, then Oracle IoT Production Monitoring

Cloud Service does not send the operator name with the operation transaction details.

In Oracle Fusion Cloud

Manufacturing, the descriptive flexfield (DFF) Work Order Operation Transactions (OperTxn_Char) has a 10 character length, by default. If your operator names are longer, you can set this length to the desired value in Oracle Fusion Cloud

Manufacturing. Any operator names longer than the OperTxn_Char character length in Oracle Fusion Cloud

Manufacturing are automatically truncated to the OperTxn_Char character length.

See Verify Work Order Status and Produced Quantities for more information on updating output quantities.