10 Production Items for KDS

The Production Item feature allows you to link menu items that are prepared in a similar manner (for example, french fries, hamburger patties) and send them to pre-selected KDS Prep Displays. This feature is designed for kitchen environments that have staff working in an assembly-line fashion. It allows the cooks to concentrate on their specialties or portions of an order.

Production items are supported in both DOM and non-DOM environments.

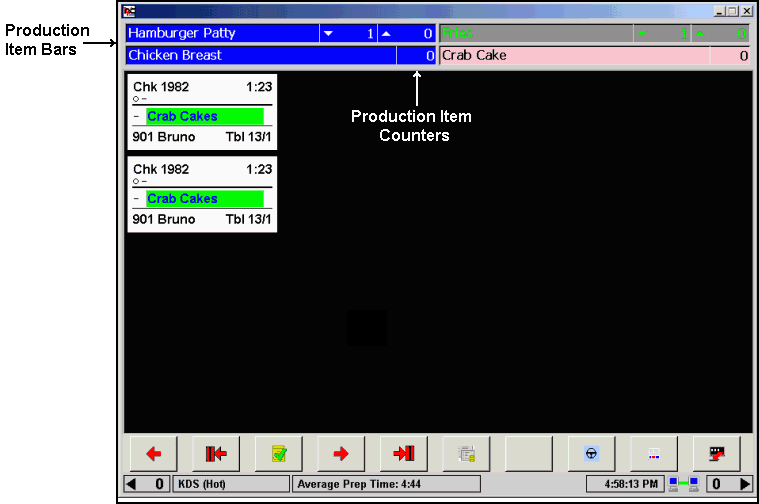

Production Bars

On the KDS, production items are grouped together in bars that span the width of the screen. You can configure the bars to appear above or below the order chits. You can show up to five production items per production bar, with the following guidelines:

-

If the number of columns configured is less than the number of production items sent, the KDS starts another production bar. For example, if the KDS device allows up to five production items to show per production bar, but only three production items are sent to the display, the KDS spaces the three bars to fill out the entire horizontal width of the display. It does not insert blank columns to fulfill the five-column maximum.

-

If the number of columns configured is greater than the number of production items sent, the KDS fills the bar with the number of columns that are available. For example, if the defined maximum is four production items, but seven production items are sent to the display, the KDS displays four columns in the first line, then the remaining three on the second line. The columns on the second line retains the column widths from the first row, inserting, in this scenario, a blank fourth column to complete the bar.

Figure 10-1 KDS Display With a Production Bar

Production Item Counters

Production items listed on the KDS Display include a name and at least one counter to track the number of portions that the prep cook must make. The number of counters depend on whether the production items are tracked individually or relative to other items on the check (for example, using item preparation times).

A single production item counter is used when a simple count of the production items is required. All items start immediately and the count increments and decrements when those production items are added or bumped from the screen. You can use a single counter in both DOM and non-DOM environments.

-

1 Burger Combo (1 patty)

-

Cheeseburger Deluxe (1 patty)

-

Burger Platter (1 patty)

-

Double Burger Platter (2 patties)

All of these menu items are linked to a production item called Hamburger Patty. A check is started that includes one of each item. When the order is sent to the kitchen, at the top of the KDS Display, the Hamburger Patty production item counter automatically increments by five. The prep cook responds by putting five patties on the broiler. When the burgers are prepared and the prep cook bumps the order chits from the display, the production count decrements by five.

When using item preparation times, a single counter is not sufficient. This is because production items are no longer tracked as individual events, but as part of a larger order. To ensure that all parts of the order are served at their best, prep cooks might have to wait before starting on the production item while other parts of the order are prepared. In this case, two counters are required. These are referred to as Under and Over counters. During operations, the Over counter shows how many portions must be started immediately, while the Under counter indicates how many will be needed soon. This method works best in a non-DOM environment.

Menu item voids can also decrement production counters if the item is still in the kitchen at the time of the void. Since production counters only track the number of portions remaining preparation, they are not affected by completed items or previous round voids.

Shelf Life

The shelf life of a production item determines when to start preparation on the item. This is similar to an item prep time, in that it specifies the amount of time needed to prepare the production item before the order is plated. The difference is that the production item is not a separate menu item. It is part of another menu item. Therefore, the shelf life represents a portion of the menu item’s prep time. That is, it is the amount of time needed to prepare the production item before its parent item is completed.

Considerations for Production Item Set Up

You can link production items to menu items (for example, an order of fries) or to condiments (for example, the side of fries that completes a combo meal). The following table provides a list of considerations when linking each to production items:

Table 10-1 Production Item Set Up Considerations

| Included with Parent Menu Item | À La Carte Menu Item | Condiment or Side Item |

|---|---|---|

|

|

|

Tasks to Configure Production Items for KDS

-

Adding a Production Summary button to the KDS toolbar or bump bar. See Configuring the KDS Bump Bar or Configuring the KDS Bump Bar for instructions.