Replenishment Sub Processes

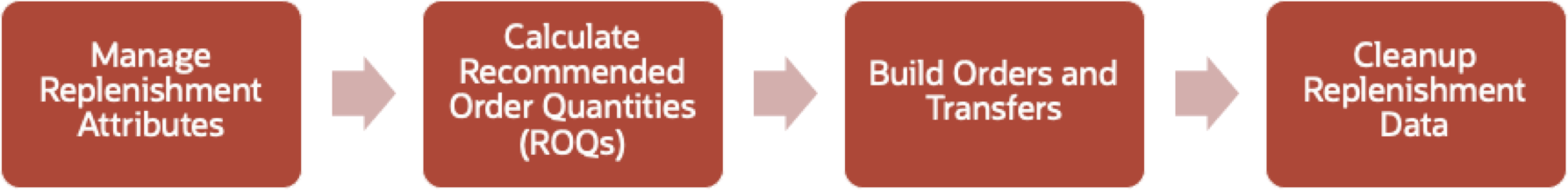

Replenishment can be divided into four major sub-processes:

Manage Replenishment Attributes

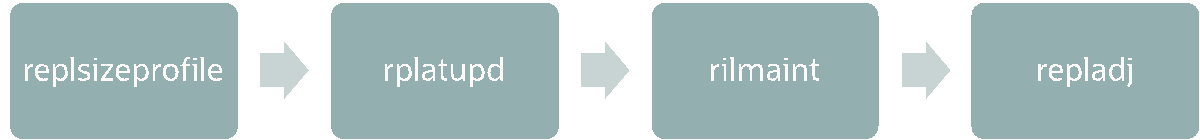

Replenishment attributes are set up for item/locations, or higher levels, using the Merchandising UI or uploaded from an external system using one of the supported integration methods. Attribute updates managed at levels higher than item/location or that are scheduled for future updates require backend processing to help manage the updates. Additionally, for some methods or configurations, there is other supporting data that requires batch processes to periodically refresh data, including that for size profiles and maximums for Floating Point replenishment.

-

Update Replenishment Size Profile (replsizeprofile) is used to copy size profile information from Allocation to Merchandising. If used, the size profiles in this table are used to spread attributes from the parent item/diff level down to the transaction item level.

-

Update Replenishment Calculation Attributes (rplatupd) is used to stage updates, when replenishment attributes are updated at a level above transaction item/location in Merchandising. This includes attributes maintained using item lists, parent items, location lists, or other location groupings.

-

Update Replenishment Calculation Attributes by Item/Locrilmaint) works in conjunction with the Update Replenishment Calculation Attributes process, but is used to update certain attributes of items and item/locations to the replenishment working tables, such as store order multiple, item status, pack sizes, and so on.

-

Recalculate Maximum Levels for Floating Point Replenishment (repladj) is used to calculate the maximum level for all item/locations set up to use the Floating Point replenishment method based on sales history.

Calculate Recommended Order Quantities

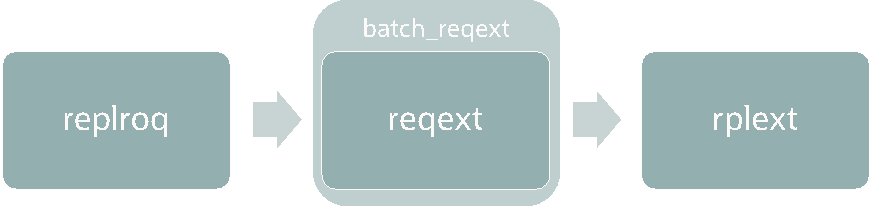

The next section of replenishment programs are focused around generating recommended order quantities (ROQs). Many user and batch processes combine to calculate ROQ. Item/location combinations follow different paths to calculate ROQ depending on whether they are replenished from a warehouse or from a supplier.

-

Calculate Net Inventory (replroq.ksh) is used to calculate the net inventory values that are used throughout the replenishment batch processing.

-

ROQ Calculation and Distribution for Item/Locs Replenished from WH (reqext) is used to calculate and create orders for item/stores that are sourced from warehouses. The batch_reqext process is used to run reqext with multiple threads.

-

ROQ Calculation and Distribution for Item/Locs Replenished from Supplier (rplext.ksh) evaluates all other item/locations not processed by reqext and calculates recommended order quantities. These are written to REPL_RESULTS to be built into orders in a later process.

If using the Investment Buy feature in Merchandising, then there are two other programs that are relevant for ROQ calculation:

Build Orders and Transfers

This section of programs create purchase orders and transfers based on the calculated ROQs.

-

Split Replenishment Orders Among Suppliers (supsplit) splits recommended order quantities using the ratios defined for an item/location, if using the supplier distribution ratios feature.

-

Build Replenishment Orders (rplbld) uses ROQs and investment buy results to build replenishment orders, including grouping like line items together to consolidate orders, where possible.

-

Scale Purchase Orders Based on Supplier Constraints (supcnstr) scales POs based on supplier constraints. See the Purchase Order chapter for details on this process.

-

Truck Splitting Optimization for Replenishment (rplsplit) splits POs and Allocations to optimize truck loads

-

Approve Replenishment Orders (rplapprv) reviews all orders created as part of the replenishment process and determines which orders can be approved. In order to be approved, an order must have an order control of Automatic and must meet vendor minimums.

Additional batch processes that may apply for this section of batches, depending on your implementation:

-

Update Replenishment Order Taxes (batch_rplapprvgtax.ksh) updates tax information when configured to run Brazil Tax as your default tax type.

-

Sync Replenishment Franchise Orders (repl_wf_order_sync.ksh) creates appropriate franchise orders for approved allocations created during replenishment

Cleanup Replenishment Data

The programs in this section are used to clean up temporary tables used in the above programs, or to remove historical attribute and result information.

-

Purge Scheduled Replenishment Induction Staging Tables (repl_indctn_purge.ksh) - see the Merchandising Operations Guide Volume 2 for details on integrating replenishment attributes from an external source.

There is also an option of running a background process for some of the above cleanup jobs, as an alternative to running during the batch schedule. The background job options are: