Cycle Count Inventory Updates

Deferred vs Immediate Mode

Oracle WMS Cloud allows you to approve/reject inventory adjustments before any real changes are made to warehouse inventory. This process, called the “Deferred Mode”, is enabled at both the Facility and Company levels.

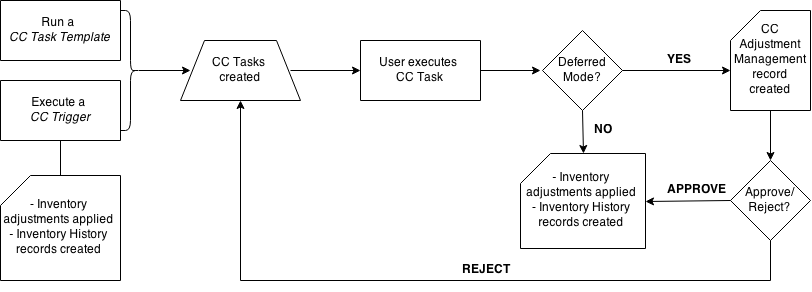

Refer to the following diagram for a high-level process flow of the Deferred Mode:

To enable Deferred Mode for your facility, set the Facility and Company parameters “INVN_ADJUSTMENT_APPROVAL_REQUIRED” to “YES”. If this parameter is set to “NO” at either the facility or company level, the “Immediate Mode” (default) will be enabled – in this mode, Cycle Count inventory adjustments are applied immediately. Note that in 3PL environments, this parameter must be set to “YES” at the child company level. Below are the possible configurations:

| PARAMETER CONFIGURATION | RESULTING BEHAVIOR | ||

| Facility Parameter ‘INVN_ADJUSTMENT_APPROVAL_REQUIRED’ | Company Parameter‘INVN_ADJUSTMENT_APPROVAL_REQUIRED’ | Write record in ‘Inventory Adjustments Management’ screen? | Inventory Adjustments Mode |

| NO | NO | NO | Immediate |

| NO | YES | NO | Immediate |

| YES | NO | NO | Immediate |

| YES | YES | YES | Deferred |

In the Deferred Mode, WMS keeps track of all Cycle Counts in the Cycle Count Adjustment screen.

This UI screen displays detailed information about the Cycle Count record.

- Group Number (group_nbr): Must be equal to the ‘Inventory History’ group

number. In Deferred Mode, inventory adjustments need to get posted with the same

group number in the ‘Inventory History’ table. The group number must be the same for

all adjustments done in a specific location (when CC is done at the location level)

or to a specific LPN (when CC is done at the LPN level) in one transaction. Note:

Transaction is defined here as:

- For RF CC_Location modules: Time between Location scan until ‘Ctrl-E- End Location Count’ is entered.

- For RF_CC LPN module: Time between LPN is scanned until ‘Ctrl-P’ is entered to finish the LPN count.

- Company (company_code): Company where the transaction is performed. Note that parent level users are able to cycle count inventory at the child level, so child company code should be displayed here for this scenario.

- Facility (facility_code): Facility where user performing the count has logged in.

- Status (status): Current status of the adjustment record.

- RF screen name: Name of the RF transaction used to perform the Cycle Count.

- Total Expected Qty: Sum of current_qty (in units) of all the inventory in the location (CC at the Location level) or LPN (CC at the LPN level) before cycle count is performed.

- Total Count Qty: Sum of counted quantity (in units) during the execution of cycle count transaction for the location (CC at the Location level) or LPN (CC at the LPN level).

- Total Adjusted Qty: Total Count Qty – Total Exp Qty

- Location (location): Location where the CC transaction was executed. For CC at the LPN level, this field should be equal to the Location where the LPN was located at the time the count was performed.