Opportunistic Cycle Count

The opportunistic cycle count facilitates pickers to perform a quick count for the location in certain given conditions (either when inventory hits zero or if the inventory is below the defined threshold) when performing picking. Without impacting the pickers productivity, the inventory discrepancies can be captured at the earliest as and when the picker is working on the warehouse floor. This functionality has following two modes:

- Pick to Zero

- Threshold Based Summary Count

The following picking modules are capable of performing the opportunistic cycle count:

- Pack NC Active {order} (rf.outbound.cwrfpackncactiveorder)

- Pack {oblpn} (rf.outbound.cwrfpacklpn)

- Pick {iblpn} (rf.outbound.cwrfpickiblpn)

- IBLPN Pick for Consolidate Replenishment (rf.outbound.cwrfpickiblpnreplen)

- Pick Cart (rf.outbound.cwrfpickcart)

- Move LPN (rf.inbound.cwrfmovelpn

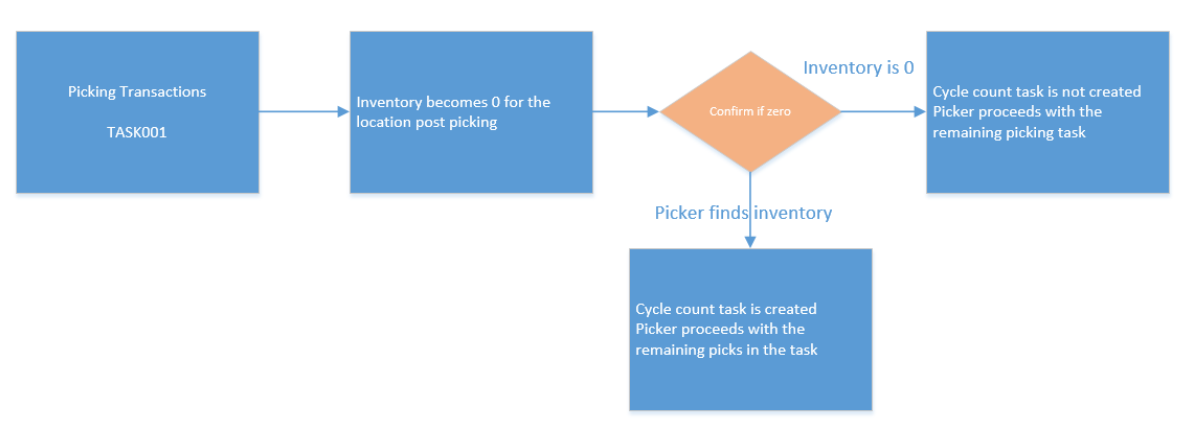

Pick to Zero

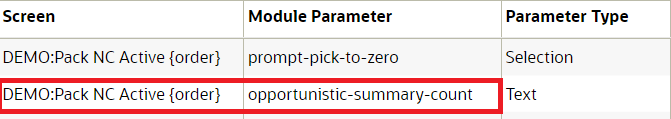

You need to configure the RF screen parameter “‘prompt-pick-to-zero’” in your picking module.

When prompt-pick-to-zero is set Yes for the picking transaction and the inventory for location becomes zero after completion of picking for that location, the system prompts the picker: “has location <location barcode> inventory reached zero? (Y/N)”. Based on the picker’s input, either ‘Y’ (Yes) or ‘N’ (No.), the system proceeds with rest of the picking task.

- If the picker responds with ‘Yes’ (Y) confirming that the inventory for location is zero and thereby no discrepancy was noticed, and a cycle count task will not be created.

- If the picker responds with ‘No’ (N) confirming that the inventory for

location is not zero, signifies that the picker has noticed a discrepancy between

the system and the floor. A cycle count task will be created for the location based

on the new cycle count trigger ‘Location Picked to Zero Discrepancy.’

To configure the Pick to Zero in your picking transaction:

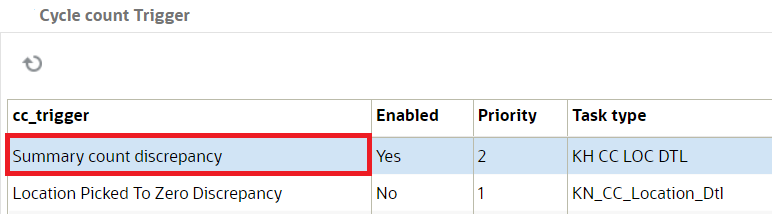

- Go to Cycle Count Trigger > enable Location Picked to Zero

Discrepancy”, and populate with an appropriate CC task type.

Note: The Location Picked to Zero Discrepancy parameter will be disabled by default.

- Configure the task type for either CC-LOCATION or CC-LOCATION-DTL for the Location Picked to Zero Discrepancy CC trigger.

- Go to the RF parameter ‘prompt-pick-to-zero’ and set it to ‘Yes’ for the picking modules where pick to zero will be applicable.

- Click Save.

On confirming the location inventory is zero or non-zero when picking from the reserve location , the system writes IHT 38 for the location with REF_CODE_3 as “PTZ” and REF_VALUE_3 as “Yes” (for zero) and REF_CODE_3 as “PTZ” and REF_VALUE_3 as “No (for non-zero), respectively.

On confirming the location inventory is zero or non-zero when picking from the active location , the system writes IHT 37 for the location with REF_CODE_3 as “PTZ” and REF_VALUE_3 as “Yes (for zero) and REF_CODE_3 as “PTZ” and REF_VALUE_3 as “No (for non-zero), respectively.

Threshold Based Summary Count

In this mode, the system launches the Summary Based Cycle Count screen once the location inventory reaches a particular threshold, allowing pickers to count the location after picking inventory from the location.

You can configure the threshold for location by threshold percentage and threshold UoM for the location.

Key pointers:

- The screen will not be launched if is an existing cycle count tasks in progress.

- Even if the CC trigger is enabled and if there is existing detailed CC task or a CC task of the same task type is present in the location, the task will not be generated.

- The threshold percentage will consider cumulative quantity of the location inventory and not for a specific SKU.

The Summary Based Cycle Count module (rf.inbound.cwrfccsummarycount) allows you to count the inventory at a summary level for a particular location. You can scan the location and count the overall quantity of the SKUs.

| RF Screen Parameter | Module name | Module description | Potential Values | Default Value |

|---|---|---|---|---|

| summary-count-for active-by | rf.inbound.cwrfccsummarycount | Summary cycle count | Single SKU/Picked SKUs/All SKUs | By default, the value is set to Blank. If the value is set to blank, the system defaults the behavior to Single SKU mode. |

Standalone Summary Cycle Count

When you are performing stand-alone summary cycle count for an active location, you can configure the summary-count-for active-by with following values:

- Single SKU/Blank (Default): An active location can be considered to be single SKU location is the location is remained with a single SKU post picking from the location.

- Picked SKUs: Not Applicable. Picked SKU is not applicable for Standalone mode.

- All SKUs: In all SKU mode you can scan all the SKUs in the location. This mode also allows to count SKUs that are not accounted for the location. IN all SKU Mode, you are required to scan each SKU and enter the respective quantity.

On performing summary cycle count for reserve locations, you are required to count the number of LPNs, or Pallets present in the location.

- For Pallet Prompt: All the LPNs in the reserve location have to be palletized.

- For LPN Prompt: If LPNs are not palletized for the location or combination of palletized and non-palletized containers, or LPN as Physical pallet.

Summary Count through Picking Transactions

On reaching the location threshold for an active location post picking, summary cycle count screen is launched if the corresponding picking transaction is configured with opportunistic -summary-count.

Opportunistic Cycle Count will support the following modes for an Active location:

- Single SKU/Blank (Default): An active location can be considered to be single SKU location because the location holds remaining single SKU post picking from the location. Once picking is complete from an active location, the summary cycle count screen is launched when the location is left with only one SKU and the location threshold is reached post picking. Enter the count of the defaulted SKU remaining post picking.

- Picked SKUs: In Picked SKU mode, enter the counts of the SKUs you have

picked. You as a picker are not required to count the SKUs that are not picked from

the location in the Picked SKU mode.

- Enter the count of the defaulted SKUs post picking (system defaults only the Picked SKUs). Enter the count of the defaulted SKUs in terms of the allocation UOM or in terms of units or both.

- In case the allocation UOM used for allocation is units, then you are required to provide the SKU count in units alone. On ending the location count by hitting the CTRL+E hot key without counting the SKUs completely, the system displays the message; "Not all item(s) counted for the Location, Proceed further?".

- If you end the count without counting all the SKUs under focus, a cycle count task will be created. This cycle count task will be based on the count discrepancy and the task type defined in the ‘Summary count discrepancy’ trigger (unless the expected quantity for the location or the SKU in focus is zero). Pressing CTRL-W or CTRL-X without completing the count will prompt the following message: Count not completed for the location, proceed?

- All SKUs: In all SKU mode, you can scan all the SKUs in the location. This

mode also allows to count SKUs that are not accounted for the location. In all SKU

mode, scan each SKU and enter the respective quantity. You can scan the SKU and

enter the respective quantities for each SKU. Note: The location count does not get auto closed unlike the Single SKU and Picked SKU mode

- On hitting CTRL+E to end the location count without counting the SKUs completely, the system will message; "Not all item(s) counted for the Location, Proceed further?".

- Accepting the warning message will redirect you to the remaining picking flow. Rejecting the message will bring you to the Summary screen again.

- If you end the count without counting all the SKUs under focus, a cycle count task will be created based on the count discrepancy and the task type defined in the ‘Summary count discrepancy’ trigger. Pressing CTRL-W or CTRL-X without completing the count will prompt the following message: Count not completed for the location, proceed?

To receive an alert of the summary cycle counts in the IHT-37 - Active Location Cycle Count Complete and in the IHT-38- Reserve Location Cycle Count Complete, the ref codes and the corresponding ref values are captured. Please refer to the IHT Documentation for more information.

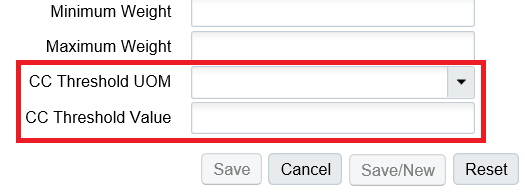

Configuring CC Threshold in Location

You need to configure the threshold value and the threshold UOM in the Location UI. The summary cycle count screen is launched during picking when the location inventory count goes blow the threshold quantity defined at the location level. By default, the field threshold quantity is set to 0.

You can also configure CC Threshold Value, CC Threshold UOM via location interface file (XML/Excel/PSV).

To configure the Threshold Based Summary Count in your picking transaction:

- Go to Cycle Count Trigger > enable ‘Summary count discrepancy’

and populate with an appropriate CC task type. Note: The parameter will be

disabled by default.

- You can configure the Summary Count discrepancy CC trigger with either CC-LOCATION or CC-LOCATION-DTL task type. Click Save.

- Go to you picking module > screen parameter > configure opportunistic

-summary-count parameter with a valid screen name of the summary

cycle count module.

- When you set the parameter 'Blank', Opportunistic summary count functionality will be disabled for the associated Picking transaction.

- When the parameter is configured with a valid summary cycle count screen name, Opportunistic Summary Count will be enabled for the picking transaction and when inventory in a location goes below threshold value configured post picking, the summary count screen will be launched.

- Click Save.

For more information, please refer to the What's New Documentation.