9 Products Menu

Used for the Routing Engine module.

-

Probability Rules: Available if Use Routing Engine is selected at the Tenant screen.

-

Probability Rule Wizard: Available if Use Routing Engine is selected at the Tenant screen.

-

Browse Probability Rules: Available if Use Routing Engine is selected at the Tenant screen.

-

-

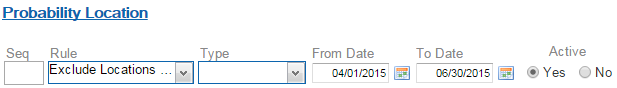

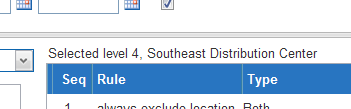

Probability Location: Available if Use Routing Engine is selected at the Tenant screen.

-

Probable Quantity Rules: Available if Use Routing Engine is selected at the Tenant screen.

-

Edit Probable Quantity Rule: Available if Use Routing Engine is selected at the Tenant screen.

-

-

Probable Quantity Location: Available if Use Routing Engine is selected at the Tenant screen.

Products

Purpose: Use the Products screen to review or work with products, or items, in the Order Broker database. Products in the database are visible in locate items searches conducted from an integrated system, such as Order Management System or Xstore.

Used for the Routing Engine module.

Product relationships: See Product, System Product and Product Location for an overview of the relationships among Order Broker elements, including products.

How to display this screen: Select Products from the Home Screen or from the Products Menu.

Note:

Only users with Products authority can display this screen. See the Role Wizard for more information.How are products created in the Order Broker database?

Typically, you create products through a product import integration with your external system of record. The process you use to download products from an integrated system varies based on the integration. See Importing Items/Products, Inventory, Barcodes, and Locations into the Database for an overview.

Important:

You should not normally create products by completing the entry fields at the top of the Products screen. Instead, you should always create and update product and related information through import from the external systems (such as Order Management System or Xstore. See Importing Items/Products, Inventory, Barcodes, and Locations into the Database for background.Options at this screen

| Option | Procedure |

|---|---|

| create a product Note: Normally, you should not create products using this method. By creating a product in Order Broker directly rather than using the process described under Importing Items/Products, Inventory, Barcodes, and Locations into the Database, you run the risk that product information will be inconsistent with that in the external systems, such as Order Management System or Xstore. |

Note: If you click Cancel after advancing to the New Product screen, the product is not created. |

| search for a product |

When you first advance to this screen, no products are displayed. The organization associated with your Default Shipping System is selected by default. Click Search to retrieve the first 50 products in your organization, or use any combination of the fields at the top of the screen to restrict the search results to matching products:

Case? All the enterable fields on this screen are case-insensitive for searching; for example, an entry of a or A matches a product code of ABC1234. |

| select a product for review or maintenance |

Click the edit icon ( Note: If the Edit Product screen is already open in another tab, you advance to that screen, with the previously-selected product displayed. |

| delete a product |

Click the delete icon ( Note: You can delete a product only if there is not an existing system product or product location for the product; however, if there are no system product or product location records, any existing product UPC codes or product attributes are deleted. You might need to delete a product if it was created inadvertently in the default system and later deleted there. For example, this situation can occur if you inadvertently generated extra SKU's of an item in Order Management System. In this situation, deleting the product in Order Broker is necessary because deleting the SKU in Order Management System does not automatically delete the product in Order Broker. |

| advance to the System Products screen |

Click the systems icon ( Note:If the System Products screen is already open in another tab, you advance to that screen, with the system products for the previously-selected product displayed. |

| advance to the Product Locations screen |

Click the locations icon ( Note: If the Product Locations screen is already open in another tab, you advance to that screen, with the product locations for the previously-selected product displayed. |

| advance to the Product Attributes screen |

Click the attributes icon ( Note: If the Product Attributes screen is already open in another tab, you advance to that screen, with the product attributes for the previously-selected product displayed. |

| advance to the UPC screen |

Click the UPC icon ( Note: If the UPC screen is already open in another tab, you advance to that screen, with the UPC barcodes for the previously-selected product displayed. |

Fields at this screen

| Field | Description |

|---|---|

| Search/new fields: | |

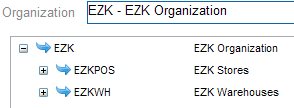

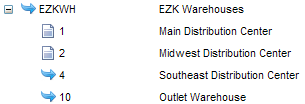

| Organization |

See organization. Defaults from the organization associated with the Default Shipping System from your user profile, but you can override this default. |

| Product |

See product. Product codes can be 1 to 35 positions in length. Enter a full or partial product code and select Search to display products whose codes start with your entry. Not case-sensitive for searching; an entry of A or a matches a product code of A12345. |

| System Product |

See system product. System product codes can be 1 to 35 positions in length. Enter a full or partial system product code and select Search to display products that have any system product codes that start with your entry. The system product code itself is not displayed with the search results. Not case-sensitive for searching; an entry of A or a matches a product code of A12345. |

| Name |

The Name of a product. Product names can be 1 to 40 positions in length. Enter a full or partial name and select Search to display products whose names start with your entry. Not case-sensitive for searching; an entry of A or a matches a product name of Arabica Coffee Beans. |

| Master Style |

See master style. Master styles can be 1 to 35 positions in length. Enter a full or partial master style and select Search to display products whose master styles start with your entry. Not case-sensitive for searching; an entry of A or a matches a master style of A12345. |

| Results fields: | |

| Organization |

See organization. |

| Product |

See product. |

| Name |

The Name of a product. |

| Master Style |

See master style. |

| Systems |

Select the systems icon ( Note: If the System Products screen is already open in another tab, you advance to that screen, with the system products for the previously-selected product displayed. |

| Locations |

Select the locations icon ( Note: If the Product Locations screen is already open in another tab, you advance to that screen, with the product locations for the previously-selected product displayed. |

| Attributes |

Select the attributes icon ( Note: If the Product Attributes screen is already open in another tab, you advance to that screen, with the product attributes for the previously-selected product displayed. |

| UPC |

Select the UPC icon ( Note: If the UPC screen is already open in another tab, you advance to that screen, with the UPC barcodes for the previously-selected product displayed. |

| Edit |

Select the edit icon ( Note: If the Edit Product screen is already open in another tab, you advance to that screen, with the previously-selected product displayed. |

| Delete |

Select the delete icon ( Note: You can delete a product only if there is not an existing system product or product location for the product; however, if there are no system product or product location records, any existing product UPC codes or product attributes are deleted. |

New Product

Purpose: Use the New Product screen to work with a product or review the date and time when it was last updated.

Used for the Routing Engine module.

Product relationships: See Product, System Product and Product Location for an overview of the relationships among Order Broker elements, including products. Also, see the Products screen for more information on how products are created in Order Broker.

How to display this screen: Begin the entry of a new product at the Products screen and click New.

Note:

Only users with Products authority can display this screen. See the Role Wizard for more information.Completing entry of a product

Update any of the fields described below and click Save, or click Cancel to return to the Products screen without saving the new product. The Organization, Product, and Name fields are required.

Note:

Any changes you make at this screen can be overwritten the next time you import product information, as described in Importing Items/Products, Inventory, Barcodes, and Locations into the Database.Fields at this screen

| Field | Description |

|---|---|

| Organization |

See organization. The organization code is separated from the organization description by a hyphen (-). Required. |

| Product |

The product code can be 1 to 35 positions long, and must be unique in your organization. See product for more information. Required. |

| Product fields: | |

| Name |

The Name of a product. Product names can be 1 to 40 positions in length. Required. |

| Master Style |

See master style. Optional. Note: Normally, you would never change the master style for a product in Order Broker. |

| Image URL |

The URL of the product image to display in Store Connect. Up to 255 positions. Optional. Must be a validly formatted URL, such as https://www.example.com/folder/image.png, where:

The screen does not validate that an image is found at the specified URL. |

| Classification fields: | |

| Department |

The description of the product’s department. The department description can be 1 to 40 positions in length, and is informational only. Optional. Order Management System integration: If your default system is an Order Management System company, this field is the description of the item/SKU’s Long SKU Department. Long SKU departments are used to identify items within a retail hierarchy. |

| Class |

The description of the product’s class. The class description can be 1 to 40 positions in length, and is informational only. Optional. Order Management System integration: If your default system is an Order Management System company, this field is the description of the item/SKU’s Long SKU Class. Taken from the base item rather than the SKU if this is a SKU’d item. Long SKU classes can be used together with long SKU departments to identify items within a retail hierarchy. |

| Category |

The description of the product’s category. The Category description can be 1 to 40 positions in length, and is informational only. Optional. Order Management System integration: If your default system is an Order Management System company, this field is the description of the item/SKU’s Long SKU Division. Long SKU divisions can be used together with long SKU departments and classes to identify items within a retail hierarchy. |

Edit Product

Purpose: Use the Edit Product screen to work with an existing product or review the date and time when it was last updated.

Used for the Routing Engine module.

Product relationships: See Product, System Product and Product Location for an overview of the relationships among Order Broker elements, including products. Also, see the Products screen for more information on how products are created in Order Broker.

How to display this screen: Click the edit icon (![]() ) for an

existing product at the Products screen.

) for an

existing product at the Products screen.

Only users with Products authority can display this screen. See the Role Wizard for more information.

If the Edit Product screen was already open in another tab when you clicked the edit icon, you advance to this screen with the previously-selected product displayed.

Updating a product: Update any of the fields described below and click Save, or click Cancel to return to the Products screen without making any changes.

Note:

Any changes you make at this screen can be overwritten the next time you import product information, as described in Importing Items/Products, Inventory, Barcodes, Images, and Locations into the Database.Fields at this screen

| Field | Description |

|---|---|

| Organization |

See organization. |

| Product |

See product. |

| Product fields: | |

| Name |

The Name of a product. Product names can be 1 to 40 positions in length. Required. |

| Master Style |

See master style. Optional field. Note: Normally, you would never change the master style for a product in Order Broker. |

| Image URL |

The URL of the product image to display in Store Connect. Up to 255 positions. Optional. Must be a validly formatted URL, such as https://www.example.com/folder/image.png, where:

The screen does not validate that an image is found at the specified URL. |

| Classification fields: | |

| Department |

The description of the product’s department. The department description can be 1 to 40 positions in length, and is informational only. Optional. Order Management System integration: If your default system is an Order Management System company, this field is the description of the item/SKU’s Long SKU Department. Long SKU departments are used to identify items within a retail hierarchy. |

| Class |

The description of the product’s class. The class description can be 1 to 40 positions in length, and is informational only. Optional. Order Management System integration: If your default system is an Order Management System company, this field is the description of the item/SKU’s Long SKU Class. Taken from the base item rather than the SKU if this is a SKU’d item. Long SKU classes can be used together with long SKU departments to identify items within a retail hierarchy. |

| Category |

The description of the product’s category. The Category description can be 1 to 40 positions in length, and is informational only. Optional. Order Management System integration: If your default system is an Order Management System company, this field is the description of the item/SKU’s Long SKU Division. Long SKU divisions can be used together with long SKU departments and classes to identify items within a retail hierarchy. |

| Last updated fields: | |

| Date |

The last date and time when the product was updated, either through the product import process or interactively. Display-only. |

System Products

Purpose: Use the System Products screen to review or work with existing system products, or create a new one.

Used for the Routing Engine module.

What is a system product? A system product is an identification of a product within a particular system that integrates with Order Broker.

Created how? A system product is created for a product when you import items or products from an external system, such as OCDS or Merchandising Omni Services, Order Management System, or Xstore. See Importing Items/Products, Inventory, Barcodes, and Locations into the Database for an overview.

Product relationships: See Product, System Product and Product Location for an overview of the relationships among Order Broker elements, including system products.

How to display this screen: Click the system product icon

(![]() ) next to a product at the Products screen.

) next to a product at the Products screen.

Note:

-

Only users with Products authority can display this screen. See the Role Wizard for more information.

-

If the System Products screen was already open in another tab when you clicked the system product icon, you advance to this screen with the system products for the previously-selected product displayed.

Options at this screen

| Option | Procedure |

|---|---|

| create a system product Note: Normally, you should not create system products using this method. By creating a system product in Order Broker directly rather than using the process described under Importing Items/Products, Inventory, Barcodes, and Locations into the Database, you run the risk that system product information will be inconsistent with that in the external system, such as Order Management System or Xstore. |

|

| search for a system product |

Use any combination of the fields at the top of the screen to restrict the search results to matching products:

Case? Both the enterable fields on this screen are case-sensitive for searching; for example, an entry of a does not match a system product code of ABC123. |

| change the master style for a system

product Note: Normally, you should never need to change the master style for a system product. Doing so might make the information in Order Broker inconsistent with the related information in the remote system. |

Select the edit icon ( |

| delete a system product |

Select the delete icon ( You might need to delete a system product if it was created inadvertently in the system and later deleted there. In this situation, deleting the system product in Order Broker is necessary because deleting the product in the remote system does not automatically delete the system product in Order Broker. |

Fields at this screen

| Field | Description |

|---|---|

| Informational fields: | |

| Organization |

The organization code and name are separated by a hyphen (-). |

| Product |

The product code and name are separated by a hyphen (-). |

| Search/new fields: | |

| System |

Creating a system product: Select a system from the from the System drop-down box. Required to create a system product. Searching for a system product: Optionally, select a system from the from the System drop-down box to restrict your results to this system. Only systems within the product’s organization are available for selection. |

| System Product |

Creating a system product: Enter the system product code to create. Required to create a system product. The system product code can be from 1 to 35 positions long. Searching for a system product: Optionally, enter a full or partial system product code. Case-sensitive for searching; an entry of a does not match a system product code of A12345. |

| Master Style |

Creating a system product: Optionally, enter a master style. The master style can be from 1 to 35 positions long. Searching for a system product: Optionally, enter a full or partial master style. Case-sensitive for searching; an entry of a does not match a master style of A12345. |

| Results fields: | |

| System |

See system. |

| System Product |

See system product. |

| Master Style |

See master style. |

| Edit |

Select the edit icon ( |

| Delete |

Select the delete icon ( |

Edit System Product

Purpose: Use the Edit System Product window to change the master style of an existing system product.

Used for the Routing Engine module.

For more information: See the System Products screen.

How to display this window: Click the edit icon (![]() ) at the System Products screen.

) at the System Products screen.

Note:

Only users with Products authority can display this screen. See the Role Wizard for more information.Fields at this screen

| Field | Description |

|---|---|

| Informational fields: |

All the following fields except for the Master Style are display-only. |

| Organization |

The organization code and name are separated by a hyphen (-). |

| Product |

The product code and name are separated by a hyphen (-). |

| System |

The system code is displayed. |

| System Product |

The system product code is displayed. |

| Master Style |

Enter a new master style and click Save. The master style can be from 1 to 35 positions long. |

Product Locations

Purpose: Use the Product Locations screen to review or work with existing product locations, or create a new one.

Used for the Routing Engine module. Not used by the Supplier Direct Fulfillment module.

What is a product location? A product location is a record of a product at a location where it is stocked or sold. For example, an item warehouse record in your order management system corresponds to a product location. Order Broker keeps track of availability information for the product location, including the available quantity and the date and expected quantity of any open purchase orders. The availability information is displayed at the Edit Product Location screen.

Created how? Typically, you create product locations through an integration with an external system. For example, product locations are created as part of the product import process or based on the results of an inventory inquiry. You can also create product locations through the availability update request or product update request, as well as through OCDS or Merchandising Omni Services Imports.

Note:

A system product must first exist for the product and system owning the selected location before you can create a product location. For example, if product AB123 does not exist in system 10, then you cannot create a product location for AB123 in system 10’s warehouse 1.Available quantity updated when? For an offline system, the available quantity is updated only when you perform the product import process from the system, or through the availability update request or product update request. For an online system, Order Broker updates the available quantity for the product location when it receives a response to an inventory inquiry. Typically, inventory levels in the Order Broker database are updated daily, or whenever scheduled by your systems administrator.

The available quantity is also updated through the OCDS or Merchandising Omni Services Imports.

Product relationships: See Product, System Product and Product Location for an overview of the relationships among Order Broker elements, including product locations.

How to display this screen: Click the product location icon

(![]() ) next to a product at the Products screen.

) next to a product at the Products screen.

Note:

-

Only users with Products authority can display this screen. See the Role Wizard for more information.

-

If the Product Locations screen was already open in another tab when you clicked the product location icon, you advance to this screen with the product locations for the previously-selected product displayed.

Options at this screen

| Option | Procedure |

|---|---|

| create a product location Note: Normally, you should not create product locations using this method. By creating a product location in Order Broker directly rather than using the process described under Importing Items/Products, Inventory, Barcodes, Images, and Locations into the Database, you run the risk that product location information will be inconsistent with that in the external system, such as Order Management System or Xstore. |

Note: If you click Cancel at the New Product Location screen, the product location is not created. |

| search for a product location |

Use 1 or both of the fields at the top of the screen to restrict the search results to matching product locations:

|

| select a product location for review or maintenance of availability information |

Click the edit icon ( Note: If the Edit Product Location screen is already open in another tab, you advance to that screen, where the previously-selected product location is displayed. |

| delete a product location |

Select the delete icon ( You might need to delete a product location if it was deleted in the remote system. For example, if you transfer all the inventory for an item from one warehouse in Order Management System to another, this does not automatically delete the product location in Order Broker. Note: You cannot delete a product location unless the available quantity, reserved quantity, and fulfilled quantity are all zero. |

| browse product locations |

Double-click a product location to open the Browse Product Locations window, where you can review the availability information, attributes, and other information about a product location. |

Fields at this screen

| Field | Description |

|---|---|

| Informational fields: | |

| Organization |

See organization. The organization code is separated from the organization description by a hyphen (-). |

| Product |

See product. The product you selected at the Products screen. The product code is separated from the product name by a hyphen (-). |

| Type |

Optionally, select a location type from the Type drop-down box to restrict the list of locations to this type. Only location types that have been created in the product’s organization are available for selection. |

| Search/New fields: | |

| Location |

Searching for a location: enter a full or partial location in the Location field and click Search to display product locations that match your entry. Creating a location: enter a valid location in the Location field and click New to create the product location. As you enter characters in the Location field, it displays locations that match your entry, and you can select a location. Required when creating. See create a product location, above, for more information. See location for background. The location code and the location name are separated by a hyphen (-). |

| Search Results fields: | |

| Type |

See location type. |

| Location |

See location. The location code and the location name are separated by a hyphen (-). |

| System |

The system associated with the system product and location. |

| System Product |

The system product associated with the system and location. |

| Edit |

Select the edit icon ( Note: If the Edit Product Location screen is already open in another tab, you advance to that screen, where the previously-selected product location is displayed. |

| Delete |

Select the delete icon ( |

New Product Location

Purpose: Use the New Product Location screen to complete entry of a product location and to enter availability information.

Note:

Typically, you create product locations through integrations with external systems. For example, product locations might be created as part of the product import process or based on the results of an inventory inquiry.Used for the Routing Engine module.

How to display this screen: Select a location and click New at the Product Locations screen.

Note:

Only users with Products authority can display this screen. See the Role Wizard for more information.Completing the creation of a product location: Update any of the fields described below and click Save, or click Cancel to return to the Product Locations screen without creating the product location.

Note:

Any changes you make at this screen can be overwritten the next time you import product location information, as described in Importing Items/Products, Inventory, Barcodes, Images, and Locations into the Database.Fields at this screen

| Field | Description |

|---|---|

| Informational fields: | |

| Organization |

The organization code and name are separated by a hyphen (-). |

| System Product |

The system product code and name are separated by a hyphen (-). |

| Location |

The location code and name are separated by a hyphen (-). |

| Availability fields: |

Order Management System integration: The availability calculation in Order Management System is: On hand - Protected - Reserved - Reserve Transfer - Backordered = Quantity available Note: It is important to run the Batch Purchase Order Layering program (BPOL) in Order Management System before scheduling periodic import of inventory information into Order Broker.See the Order Management System online help for more information. |

| Available Quantity |

The quantity of the product available in this location. This information can by updated through integration with an external system, or by entry at this screen. Order Broker uses this quantity to calculate the Available to Promise if:

Note: The available quantity is a maximum of 6 positions, and can be a negative number. It cannot include decimals. For more information: See the Available to Promise field at the Edit Product Location screen for a discussion. |

| Reserved Quantity |

Not implemented at the New Product Location screen. See the Reserved Quantity at the Edit Product Location screen for a discussion. |

| Fulfilled Quantity |

Not implemented on this screen. See the Fulfilled Quantity at the Edit Product Location screen for a discussion. |

| Available to Promise |

The Available Quantity minus the Reserved Quantity and the Fulfilled Quantity, if any, for the product location. This field is not implemented at the New Product Location screen. See the Calculating the Available to Promise Quantity for a discussion. |

| Next PO Date |

The next date when a purchase order for this product is expected for delivery. Order Management System integration: The date is calculated using purchase order layering, in which the expected quantity on a purchase order may be “reserved” for older backorders. See the Order Management System online help for more information. |

| Next PO Quantity |

The number of units ordered on the next purchase order. This quantity can be up to 6 positions. It cannot include decimals. |

| Attributes |

The following product attributes are available to guide selection of fulfilling or sourcing locations for orders:

|

| Daily Sell Through Quantity |

Typically represents the average quantity of the product sold in this location on a daily basis. You might use this quantity as part of a probability rule that subtracts the daily sell-through quantity from the available quantity, especially if the location is in an offline system. This quantity can be up to 6 positions, and must be a whole number. It cannot be a negative number. |

| Status |

The status of the product in this location. You might use the status as part of a probability rule that excludes discontinued products. Possible statuses are:

Required. |

| Sell Quantity/Multiple |

Typically represents the selling multiple for a product; for example, you might sell tires in quantities of 4. You might use this quantity as part of a probability rule that indicates to exclude a product location, or display an available quantity of 0, if the available quantity is lower than the sell quantity/multiple. This quantity can be up to 6 positions, and must be a whole number. It cannot be a negative number. You might also use the Minimum Sell Quantity to fulfill the same function. |

| On Clearance |

Indicates whether the product is on clearance in this location:

You might use this setting as part of a probability rule that reduces the quantity that is expected to be available to fulfill orders. Used in LocateItems Sequence and Splitting Examples (Standard Brokering) calculation. If you use LocateItems Sequence and Splitting Examples (Standard Brokering) and this flag is selected, the Science Engine uses a selling price of .01 to calculate margin. |

| Minimum Sell Quantity |

See the Sell Quantity/Multiple, above. This quantity can be up to 6 positions, and must be a whole number. It cannot be a negative number. |

| Selling Price |

The single-unit selling price of the product in this location. Can be up to 19 positions with a 4-position decimal. It can also be 0, but cannot be a negative number, and should not include a currency symbol. Optional, but should be specified if Gross Margin is used in the LocateItems Sequence and Splitting Examples (Standard Brokering) calculation. You might use the selling price in a probability rule to exclude lower-priced items. |

| Shrink Rate % |

Typically represents the percentage loss experienced for the product in this location due to theft or breakage. You might use the shrink rate as part of a probability rule that reduces the available quantity by the shrink rate percentage. This percentage can be up to 2 positions, and must be a whole number. It cannot be a negative number. |

| Cost |

The single-unit cost of the product in this location. Can be up to 19 positions with a 4-position decimal. It can also be 0, but cannot be a negative number, and should not include a currency symbol. Optional, but should be specified if Gross Margin is used in the LocateItems Sequence and Splitting Examples (Standard Brokering) calculation. You might use the cost in a probability rule to exclude higher-cost items. |

| Sales Velocity |

A numeric ranking you can use to indicate how well a product sells in a particular location. You can use the sales velocity ranks assigned to product locations as part of the criteria for selecting fulfilling or sourcing locations for orders, either through standard or weighted brokering. Numeric; 2 positions with an optional 2-position decimal. Can be blank, or any number from 0 to 99.99. See the Standard Brokering or Weighted Brokering tabs at the Preferences screen for more information. |

| Margin |

The Selling Price minus the Cost. If no Cost is specified, the Margin is equal to the Selling Price. If a Cost is specified, but no Selling Price, the Margin is negative. If no Cost or Margin is specified or if you set them to 0, the Margin is blank or 0.0000. System-calculated when either the Selling Price or Cost is entered. Display-only. |

Browse Product Locations

Purpose: Use the Browse Product Locations window to review availability information for a product location, or to check the last time this information was updated.

Used for the Routing Engine module.

Product relationships: See Product, System Product and Product Location for an overview of the relationships among Order Broker elements, including product locations. Also, see the Product Locations screen for more information on how product locations are created in Order Broker.

Updated how? The availability information displayed at this screen can be updated by:

- a periodic refresh from an external system (such as product import processing from the order management system)

- entry at the Edit Product Location screen

- the Fulfilled Inventory Export

- the availability update request

- the product update request

- an on-demand refresh triggered by a locate items search or product availability search for an online system

- OCDS or Merchandising Omni Services Imports

Order Broker uses the availability information displayed here to select a fulfilling location, or sourcing location for a ship-for-pickup order, when:

- the location is in an offline system, or

- the location is in an online system, but the Order Broker cannot communicate with the system and the No Offline Response Action setting at the Preferences screen is Use offline

Systems that use purchase order layering: The Next PO date and quantity listed might not reflect the date and quantity on the next open purchase order for a product if you integrate with a system such as Order Management System, which uses purchase order layering. In purchase order layering, the system accounts for the total quantity backordered to determine which purchase order might be able to fulfill a new order for the product. For example, the backorder quantity for a product is 115. There are 2 open purchase orders for the item, each with an order quantity of 100. Purchase order layering uses the date of the second purchase order as the Next PO Date since the full order quantity of the first purchase order is already fully committed to prior backorders. Also, it reports that the Next PO Quantity is 85, since the first 15 on the second purchase order is also already committed.

Note:

It is important to run the Batch Purchase Order Layering program (BPOL) in Order Management System before importing inventory information into Order Broker.About attributes: The product attributes (Daily Sell Through Quantity, Sell Quantity/Multiple, Minimum Sell Quantity, Shrink Rate %, and Sales Velocity) are metrics that you can define for a product location in order to use them in probability rules. For example, you might want to display an available quantity of 0 if the actual available quantity is not more than the daily sell-through quantity for an off-line location. You can also have the Routing Engine use the Sales Velocity for product location ranking.

Additional attributes (Status, On Clearance, Selling Price, Cost, and Margin) can be used as part of LocateItems Sequence and Splitting Examples (Standard Brokering).

How to display this window: Click to highlight a product location at the Product Locations screen.

Note:

Only users with Products authority can display this screen. See the Role Wizard for more information.Options at this window

| Option | Procedure |

|---|---|

| review the next product location |

Click the next icon ( |

| review the previous product location |

Click the previous icon ( |

| edit the current product location |

Select Edit to advance to the Edit Product Location screen. |

Fields at this window

Note:

All fields at this window are display-only.| Field | Description |

|---|---|

| Informational fields: | |

| Location |

The location code and name are separated by a hyphen (-). |

| System Product |

The system product code. The name is not displayed. |

| Type |

The location type code. The name is not displayed. |

| System |

The system code and name are separated by a hyphen (-). |

| Availability fields | |

| Available Quantity |

The quantity of the product available in this location as of the most recent update, before subtracting the Reserved Quantity and any Fulfilled Quantity, or applying any probability rules. This information can by updated through:

See the discussion above under Browse Product Locations for more information. Up to 6 positions, and can be a negative number. Order Broker uses this quantity to calculate the Available to Promise unless it receives an update from an online system. Probability rules: Probability rules use the Available to Promise in tests, calculations, and results. See Probability Rule Wizard for background. |

| Reserved Quantity |

The quantity on all order lines assigned to this product location that are in a status indicating the inventory is reserved for existing orders. The reserved quantity and any fulfilled quantity are subtracted from the Available Quantity to determine the Available to Promise quantity. Up to 6 positions. You can use the System screen to select the statuses that indicate an order line is reserved. In the case of ship-for-pickup orders, the reserved quantity is updated at the sourcing location. The reserved quantity displayed here is 0 if there are no order lines in a selected status assigned to this product location. For more information: See the Reservation tab at the System screen for information on selecting reserved statuses, and see Calculating the Available to Promise Quantity for an overview. |

| Fulfilled Quantity |

The quantity that has been fulfilled on delivery or pickup orders, or put in transit for ship-for-pickup orders, since the last fulfilled quantity export to the system, or inventory import from the system. The reserved quantity and any fulfilled quantity are subtracted from the Available Quantity to determine the Available to Promise quantity. Up to 6 positions. In the case of ship-for-pickup orders, the fulfilled quantity is increased at the sourcing location when the pickup location changes the status to fulfilled. Tracked when? The Track Fulfilled Quantity field at the System screen controls whether to track the fulfilled quantity and, if so, when to reset it. For more information: See the Track Fulfilled Quantity field for a discussion of how the fulfilled quantity is tracked, and see Calculating the Available to Promise Quantity for an overview. |

| Available to Promise |

Used for: The quantity for the system to use when determining the available quantity to return in the LocateItems response and the product availability search, and to evaluate locations for order assignment. Up to 6 positions, and can be a negative number. Calculation: Calculated by subtracting the Reserved Quantity and any Fulfilled Quantity from the Available Quantity for the product location. When you update the Available Quantity at this screen and press the tab key, the screen updates the Available to Promise quantity based on your entry. Probability rules: If a probability rule applies to the product location, it is calculated based on this quantity. For more information: See Calculating the Available to Promise Quantity for an overview. |

| Next PO date |

The next date when a purchase order for this product is expected for delivery. Order Management System integration: The date is calculated using purchase order layering, in which the expected quantity on a purchase order may be “reserved” for older backorders. This information is not updated automatically from Order Management System each time you enter or maintain a purchase order. Some other activity, such as a change to the available quantity above or below the specified threshold, is required to trigger an update from Order Management System to Order Broker. See the Order Management System online help for more information. |

| Next PO Quantity |

The number of units ordered on the next purchase order. This quantity can be up to 6 positions. It cannot include decimals. Order Management System integration: This information is not updated automatically from Order Management System each time you enter or maintain a purchase order. Some other activity, such as a change to the available quantity above or below the specified threshold, is required to trigger an update from Order Management System to Order Broker. |

| Last Updated |

The last date and time when this product location was updated through the product and inventory import process, Fulfilled Inventory Export, inventory inquiry, or interactively at this screen. Up to 6 positions. Not updated when Order Broker updates the Reserved Quantity or the Fulfilled Quantity. |

| Attributes |

The following product attributes are available to guide selection of fulfilling or sourcing locations for orders:

Each of the product attributes are user-defined. |

| Daily Sell Through Quantity |

Typically represents the average quantity of the product sold in this location on a daily basis. You might use this quantity as part of a probability rule that subtracts the daily sell-through quantity from the available quantity, especially if the location is in an offline system. This quantity can be up to 6 positions, and must be a whole number. It cannot be a negative number. |

| Status |

The status of the product in this location. You might use the status as part of a probability rule that excludes discontinued products. Possible statuses are:

|

| Sell Quantity/Multiple |

Typically represents the selling multiple for a product; for example, you might sell tires in quantities of 4. You might use this quantity as part of a probability rule that indicates to exclude a product location, or display an available quantity of 0, if the available quantity is lower than the sell quantity/multiple. This quantity can be up to 6 positions, and must be a whole number. It cannot be a negative number. You might also use the Minimum Sell Quantity to fulfill the same function. |

| On Clearance |

Indicates whether the product is on clearance in this location:

You might use this setting as part of a probability rule that reduces the quantity that is expected to be available to fulfill orders. Used in LocateItems Sequence and Splitting Examples (Standard Brokering) calculation. If you use LocateItems Sequence and Splitting Examples (Standard Brokering) and this flag is selected, the Science Engine uses a selling price of .01 to calculate margin. |

| Minimum Sell Quantity |

See the Sell Quantity/Multiple, above. This quantity can be up to 6 positions, and must be a whole number. It cannot be a negative number. |

| Selling Price |

The single-unit selling price of the product in this location. Can be up to 19 positions with a 4-position decimal. It can also be 0, but cannot be a negative number, and should not include a currency symbol. Optional, but should be specified if Gross Margin is used in the LocateItems Sequence and Splitting Examples (Standard Brokering) calculation. You might use the selling price in a probability rule to exclude lower-priced items. |

| Shrink Rate % |

Typically represents the percentage loss experienced for the product in this location due to theft or breakage. You might use the shrink rate as part of a probability rule that reduces the available quantity by the shrink rate percentage. This percentage can be up to 2 positions, and must be a whole number. It cannot be a negative number. |

| Cost |

The single-unit cost of the product in this location. Can be up to 19 positions with a 4-position decimal. It can also be 0, but cannot be a negative number, and should not include a currency symbol. Optional, but should be specified if Gross Margin is used in the LocateItems Sequence and Splitting Examples (Standard Brokering) calculation. You might use the cost in a probability rule to exclude higher-cost items. |

| Sales Velocity |

A numeric ranking you can use to indicate how well a product sells in a particular location. You can use the sales velocity ranks assigned to product locations as part of the criteria for selecting fulfilling or sourcing locations for orders, either through standard or weighted brokering. Numeric; 2 positions with an optional 2-position decimal. Can be blank, or any number from 0 to 99.99. See the Standard Brokering or Weighted Brokering tabs at the Preferences screen for more information. |

| Margin |

The Selling Price minus the Cost. If no Cost is specified, the Margin is equal to the Selling Price. If a Cost is specified, but no Selling Price, the Margin is negative. If no Cost or Margin is specified or if you set them to 0, the Margin is blank or 0.0000. System-calculated when either the Selling Price or Cost is entered. Display-only. |

Edit Product Location

Purpose: Use the Edit Product Location screen to review or update availability information for a product location, or to check the last time this information was updated.

Used for the Routing Engine module.

Product relationships: See Product, System Product and Product Location for an overview of the relationships among Order Broker elements, including product locations. Also, see the Product Locations screen for more information on how product locations are created in Order Broker.

Updated how? The availability information displayed at this screen can be updated by:

- a periodic refresh from an external system (such as product import processing from the order management system)

- entry at the Edit Product Location screen

- the Fulfilled Inventory Export

- the availability update request

- the product update request

- an on-demand refresh triggered by a locate items search or product availability search for an online system

- OCDS or Merchandising Omni Services Imports

Order Broker uses the availability information displayed here to select a fulfilling location or a sourcing location for a ship-for-pickup order when:

- the location is in an offline system, or

- the location is in an online system, but the Order Broker cannot communicate with the system and the No Offline Response Action setting at the Preferences screen is Use offline

Order Broker uses the availability information displayed here in the locate items response when:

- the location is in an offline system, or

- the location is in an online system, but the Order Broker cannot communicate with the system and the No Offline Response Action setting at the Preferences screen is Use offline

Systems that use purchase order layering: The Next PO date and quantity listed might not reflect the date and quantity on the next open purchase order for a product if you integrate with a system such as Order Management System, which uses purchase order layering. In purchase order layering, the system accounts for the total quantity backordered to determine which purchase order might be able to fulfill a new order for the product. For example, the backorder quantity for a product is 115. There are 2 open purchase orders for the item, each with an order quantity of 100. Purchase order layering uses the date of the second purchase order as the Next PO Date since the full order quantity of the first purchase order is already fully committed to prior backorders. Also, it reports that the Next PO Quantity is 85, since the first 15 on the second purchase order is also already committed.

Note:

It is important to run the Batch Purchase Order Layering program (BPOL) in Order Management System before importing inventory information into Order Broker.About attributes: The product attributes (Daily Sell Through Quantity, Sell Quantity/Multiple, Minimum Sell Quantity, Shrink Rate %, and Sales Velocity) are metrics that you can define for a product location in order to use them in probability rules. For example, you might want to display an available quantity of 0 if the actual available quantity is not more than the daily sell-through quantity for an off-line location. You can also have the Routing Engine use the Sales Velocity for product location ranking.

Additional attributes (Status, On Clearance, Selling Price, Cost, and Margin) can be used as part of LocateItems Sequence and Splitting Examples (Standard Brokering).

How to display this screen:

- Click Edit for a product location at the Browse Product Locations window

- Select the edit icon (

) for a location at the Product Locations screen

) for a location at the Product Locations screen

- Only users with Products authority can display this screen. See the Role Wizard for more information.

- If the Edit Product Location screen was already open in another tab when you clicked the edit icon, you advance to this screen with the previously-selected product location displayed.

Updating a product location

Update any of the fields described below and click Save, or click Cancel to return to the Product Locations screen without making any changes.

Note:

Any changes you make at this screen can be overwritten the next time you import product location information, as described in Importing Items/Products, Inventory, Barcodes, Images, and Locations into the Database.Fields at this screen

| Field | Description |

|---|---|

| Informational fields: | |

| Organization |

The organization code and name are separated by a hyphen (-). |

| System Product |

The system product code and name are separated by a hyphen (-). |

| Location |

The location code and name are separated by a space. |

| Last Updated |

The last date and time when this product location was updated through the product and inventory import process, Fulfilled Inventory Export, inventory inquiry, or interactively at this screen. Up to 6 positions. Display-only. Not updated when Order Broker updates the Reserved Quantity or Fulfilled Quantity. |

| Availability fields: | |

| Available Quantity |

The quantity of the product available in this location as of the most recent update, before subtracting the Reserved Quantity and any Fulfilled Quantity, or applying any probability rules. This information can by updated through:

See the discussion above under Edit Product Location for more information. Order Broker uses this quantity to calculate the Available to Promise unless it receives an update from an online system. Note: The available quantity is a maximum of 6 positions, and can be a negative number. It cannot include decimals. Probability rules: Probability rules use the Available to Promise in tests, calculations, and results. See Probability Rule Wizard for background. |

| Reserved Quantity |

The quantity on all order lines assigned to this product location that are in a status indicating the inventory is reserved for existing orders. The reserved quantity and any fulfilled quantity are subtracted from the Available Quantity to determine the Available to Promise quantity. Up to 6 positions. In the case of ship-for-pickup orders, the reserved quantity is updated at the sourcing location. You can use the System screen to select the statuses that indicate an order line is reserved. The reserved quantity displayed here is 0 if there are no order lines in a —toselected status assigned to this product location. Display-only. For more information: See the Reservation tab at the System screen for information on selecting reserved statuses, and see Calculating the Available to Promise Quantity for an overview. |

| Fulfilled Quantity |

The quantity that has been fulfilled on delivery or pickup orders, or put in transit for ship-for-pickup orders, since the last fulfilled quantity export to the system, or inventory import from the system. The reserved quantity and any fulfilled quantity are subtracted from the Available Quantity to determine the Available to Promise quantity. Up to 6 positions. In the case of ship-for-pickup orders, the fulfilled quantity is increased at the sourcing location when the pickup location changes the status to fulfilled. Tracked when? The Track Fulfilled Quantity field at the System screen controls whether to track the fulfilled quantity and, if so, when to reset it. Display-only. For more information: See the Track Fulfilled Quantity field for a discussion of how the fulfilled quantity is updated, and see Calculating the Available to Promise Quantity for an overview. |

| Available to Promise |

Used for: The quantity for the system to use when determining the available quantity to return in the LocateItems response and the product availability search, and to evaluate locations for order assignment. Up to 6 positions, and can be a negative number. Display-only. Calculation: Calculated by subtracting the Reserved Quantity and any Fulfilled Quantity from the Available Quantity for the product location. When you update the Available Quantity at this screen and press the tab key, the screen updates the Available to Promise quantity based on your entry. Probability rules: If a probability rule applies to the product location, it is calculated based on this quantity. For more information: See Calculating the Available to Promise Quantity for an overview. |

| Next PO Date |

The next date when a purchase order for this product is expected for delivery. Order Management System integration: The date is calculated using purchase order layering, in which the expected quantity on a purchase order may be “reserved” for older backorders. This information is not updated automatically from Order Management System each time you enter or maintain a purchase order. Some other activity, such as a change to the available quantity above or below the specified threshold, is required to trigger an update from Order Management System to Order Broker.See the Order Management System online help for more information. |

| Next PO Quantity |

The number of units ordered on the next purchase order. This quantity can be up to 6 positions. It cannot include decimals. Order Management System integration: This information is not updated automatically from Order Management System each time you enter or maintain a purchase order. Some other activity, such as a change to the available quantity above or below the specified threshold, is required to trigger an update from Order Management System to Order Broker. |

| Attributes |

The following product attributes are available to guide selection of fulfilling or sourcing locations for orders:

Each of the product attributes are user-defined. |

| Daily Sell Through Quantity |

Typically represents the average quantity of the product sold in this location on a daily basis. You might use this quantity as part of a probability rule that subtracts the daily sell-through quantity from the available quantity, especially if the location is in an offline system. This quantity can be up to 6 positions, and must be a whole number. It cannot be a negative number. |

| Status |

The status of the product in this location. You might use the status as part of a probability rule that excludes discontinued products. Possible statuses are:

Required. |

| Sell Quantity/Multiple |

Typically represents the selling multiple for a product; for example, you might sell tires in quantities of 4. You might use this quantity as part of a probability rule that indicates to exclude a product location, or display an available quantity of 0, if the available quantity is lower than the sell quantity/multiple. This quantity can be up to 6 positions, and must be a whole number. It cannot be a negative number. You might also use the Minimum Sell Quantity to fulfill the same function. |

| On Clearance |

Indicates whether the product is on clearance in this location:

You might use this setting as part of a probability rule that reduces the quantity that is expected to be available to fulfill orders. Used in LocateItems Sequence and Splitting Examples (Standard Brokering) calculation. If you use LocateItems Sequence and Splitting Examples (Standard Brokering) and this flag is selected, the Science Engine uses a selling price of .01 to calculate margin. |

| Minimum Sell Quantity |

See the Sell Quantity/Multiple, above. This quantity can be up to 6 positions, and must be a whole number. It cannot be a negative number. |

| Selling Price |

The single-unit selling price of the product in this location. Can be up to 19 positions with a 4-position decimal. It can also be 0, but cannot be a negative number, and should not include a currency symbol. Optional, but should be specified if Gross Margin is used in the LocateItems Sequence and Splitting Examples (Standard Brokering) calculation. You might use the selling price in a probability rule to exclude lower-priced items. |

| Shrink Rate % |

Typically represents the percentage loss experienced for the product in this location due to theft or breakage. You might use the shrink rate as part of a probability rule that reduces the available quantity by the shrink rate percentage. This percentage can be up to 2 positions, and must be a whole number. It cannot be a negative number. |

| Cost |

The single-unit cost of the product in this location. Can be up to 19 positions with a 4-position decimal. It can also be 0, but cannot be a negative number, and should not include a currency symbol. Optional, but should be specified if Gross Margin is used in the LocateItems Sequence and Splitting Examples (Standard Brokering) calculation. You might use the cost in a probability rule to exclude higher-cost items. |

| Sales Velocity |

A numeric ranking you can use to indicate how well a product sells in a particular location. You can use the sales velocity ranks assigned to product locations as part of the criteria for selecting fulfilling or sourcing locations for orders, either through standard or weighted brokering. Numeric; 2 positions with an optional 2-position decimal. Can be blank, or any number from 0 to 99.99. See the Standard Brokering or Weighted Brokering tabs at the Preferences screen for more information. |

| Margin |

The Selling Price minus the Cost. If no Cost is specified, the Margin is equal to the Selling Price. If a Cost is specified, but no Selling Price, the Margin is negative. If no Cost or Margin is specified or if you set them to 0, the Margin is blank or 0.0000. System-calculated when either the Selling Price or Cost is entered. Display-only. |

UPC

Purpose: Use the UPC screen to review or work with existing UPC barcodes for a product, or create a new one.

What is a UPC barcode? A UPC barcode is an identification of a product by either a UPC-A or EAN-13 code.

Created how? You can create UPC barcodes for products when you download or export items or products from an external system, such as Order Management System or Xstore. See Importing Items/Products, Inventory, Barcodes, Images, and Locations into the Database for an overview, and see Importing UPC Barcodes through File Storage API for information specific to the barcode import.

Used how? You can use UPC barcodes in Store Connect to scan picked items on orders. See the Store Connect Preferences screen for more information.

Product relationships: See Product, System Product and Product Location for an overview of the relationships among Order Broker elements, including UPC barcodes.

How to display this screen: Click the UPC barcode icon (![]() )

next to a product at the Products screen.

)

next to a product at the Products screen.

Note:

- Only users with Products authority can display this screen. See the Role Wizard for more information.

- If the UPC screen was already open in another tab when you clicked the UPC barcode icon, you advance to this screen with the UPC barcodes for the previously-selected product displayed.

Options at this screen

| Option | Procedure |

|---|---|

| create a UPC barcode Note: Normally, you should not create UPC barcodes using this method. By creating a UPC barcodes in Order Broker directly rather than using the process described under Importing Items/Products, Inventory, Barcodes, Images, and Locations into the Database, you run the risk that UPC barcode information will be inconsistent with that in the external system, such as Order Management System or Xstore. |

Note: To reassign a barcode to a different product through the screens, you need to first delete the existing barcode record and then create the new barcode record for the other product. However, you can reassign a product barcode through the import process; see Importing UPC Barcodes through File Storage API for more information. |

| search for a UPC barcode |

Use 1 or both of the fields at the top of the screen to restrict the search results to matching UPC barcodes:

Case? The barcode is case-sensitive for searching; for example, an entry of a does not match a barcode of A12345. |

| select a UPC barcode to edit the code |

Click the edit icon ( |

| delete a UPC barcode |

Select the delete icon ( |

Fields at this screen

| Field | Description |

|---|---|

| Informational fields: | |

| Organization |

See organization. The organization code is separated from the organization description by a hyphen (-). Display-only. |

| Product |

See product. The product you selected at the Products screen. The product code is separated from the product name by a hyphen (-). Display-only. |

| Search/New fields: | |

| UPC |

The barcode identifying a product. Creating a UPC barcode: Enter a complete UPC-A or EAN-13 barcode identifying the product, select the UPC Type, and click New to create the barcode. A barcode can be assigned to a single product in an organization, but each product can have multiple UPC-A and EAN-13 barcodes. Required when creating. Up to 40 positions. Searching for a UPC barcode: Enter a full or partial barcode and click Search to display barcodes that match your entry. Case-sensitive for searching; for example, an entry of a does not match a UPC of A12345. |

| UPC Type |

Creating a UPC barcode: Enter the barcode in the UPC field, select a type from the UPC Type drop-down box, and click New to create the UPC barcode. Available types are UPC-A and EAN-13, and a product can have multiple barcodes of each type. Required when creating. Searching for a UPC barcode: Select a type from the UPC Type drop-down box and click Search to position to that product location. |

| Search Results fields: | |

| UPC |

The barcode identifying a product. Up to 40 positions. |

| UPC Type |

The barcode type. Possible types are UPC-A and EAN-13. |

| Edit |

Select the edit icon ( |

| Delete |

Select the delete icon ( |

Edit UPC

Purpose: Use the Edit UPC window to update a UPC barcode for a product.

Used for the Routing Engine module.

How to display this window: Select the edit icon (![]() ) for a

UPC barcode at the UPC screen.

) for a

UPC barcode at the UPC screen.

Note:

Only users with Products authority can display this screen. See the Role Wizard for more information.Updating the UPC barcode: Update the UPC number and click Save, or click Cancel to return to the UPC screen without making a change.

Fields at this window

| Field | Description |

|---|---|

| Organization |

See organization. The organization code is separated from the organization description by a hyphen (-). Display-only. |

| Product |

See product. The product you selected at the Products screen. The product code is separated from the product name by a hyphen (-). Display-only. |

| UPC Type |

The barcode type. Possible types are UPC-A and EAN-13. Display-only. |

| UPC |

The barcode number identifying a product. Up to 40 positions. Optionally, enter a new barcode and click Save to change the barcode. Each barcode must be assigned to only a single product in an organization. |

Product Attributes

Purpose: Use the Product Attributes screen to review or work with attributes that apply to a product.

Used when? When the Attribute Type specified for the attribute is Product and Location, the attribute can filter locations when routing orders for the product. However, when the Attribute Type is Product, the attribute assignment is informational only.

For more information: See Using Attribute Rules for Delivery and Pickup Orders and Using Attribute Rules for Ship-for-Pickup Orders for background, and see Attribute Definitions for information on creating and working with attribute definitions.

Used for the Routing Engine module.

How to display this screen: Select the attribute icon (![]() )

for a product at the Products screen.

)

for a product at the Products screen.

Options at this screen

| Option | Procedure |

|---|---|

| apply a new attribute to the product |

Click New to open the New Product Attribute window. |

| search for a product attributes |

Optionally, enter a full or partial attribute code in the Attribute Code field to restrict your results to attributes whose codes start with your entry. Optionally, select a Data Type to restrict your results to attributes whose Data Types match your entry. Click Search. |

| select a product attribute for maintenance and review |

Click the edit icon ( |

| delete an attribute |

Click the delete icon ( |

Fields at this screen

| Field | Description |

|---|---|

| Informational fields: | |

| Organization |

See organization. The organization code is separated from the organization description by a hyphen (-). |

| Product |

See product. The product you selected at the Products screen. The product code is separated from the product name by a hyphen (-). |

| Search fields: | |

| Attribute Code |

The Code identifying an attribute you can apply to products. Optionally, enter a full or partial attribute code and click Search to display product attributes that start with your entry. |

| Data Type |

Indicates the type of data that can be defined through the attribute. Available data types are:

Optionally, select a Data Type and click Search to display product attributes that match your selection. |

| Results fields: | |

| Attribute Code |

The Code identifying an attribute applied to the product. |

| Description |

The description of the attribute. Can be up to 100 positions. Truncated if it exceeds the allotted space. |

| Value |

The value of the product attribute. The value can be:

A text or list value can be up to 50 positions. Numbers can be up to 25 positions, including commas, decimal points, or minus signs. Truncated if it exceeds the allotted space. |

| Data Type |

Indicates the type of data that can be defined through the attribute. Available data types are:

|

| Edit |

Select the edit icon ( |

| Delete |

Select the delete icon ( |

New Product Attribute

Purpose: Use the New Product Attribute window to apply an attribute to a product.

Used for the Routing Engine module.

Used when? When the Attribute Type specified for the attribute is Product and Location, the attribute can filter locations when routing orders for the product. However, when the Attribute Type is Product, the attribute assignment is informational only.

For more information: See Using Attribute Rules for Delivery and Pickup Orders and Using Attribute Rules for Ship-for-Pickup Orders for background.

Assigning attributes to locations or products: Use the New Location Attribute and New Product Attribute screens to assign attributes.

How to open this window: Click New at the Product Attributes screen.

Fields at this window: Complete the fields described below and click Save, or click Cancel to return to the Product Attributes screen without creating the product attribute.

| Field | Description |

|---|---|

| Product |

See product. The product you selected at the Products screen. The product code is separated from the product name by a hyphen (-). Display-only. |

| Attribute Code |

Select the Code identifying an attribute you can apply to a product. All attribute definitions that could be applied to the selected product are available for selection. Attributes are eligible if:

Once you select an Attribute Code, the Description and Data Type are displayed above the Value field. Required. |

| Description |

The description of the selected attribute. Display-only. |

| Data Type |

Indicates the type of data that can be defined through the selected attribute. Possible data types are:

Display-only. |

| Value |

Use this field to enter or select the value for the product attribute. If the Data Type is:

Required, except that a Boolean defaults to selected and is display-only. |

Edit Product Attribute

Purpose: Use the Edit Product Attribute window to change the value for an attribute applied to a product.

Used for the Routing Engine module.

Used when? When the Attribute Type specified for the attribute is Product and Location, the attribute can filter locations when routing orders for the product. However, when the Attribute Type is Product, the attribute assignment is informational only.

For more information: See Using Attribute Rules for Delivery and Pickup Orders and Using Attribute Rules for Ship-for-Pickup Orders for background.

How to open this window: Click the edit icon (![]() ) at the Product Attributes screen.

) at the Product Attributes screen.

Fields at this window: Complete the fields described below and click Save, or click Cancel to return to the Product Attributes screen without updating the product attribute.

Note:

Boolean product attributes cannot be edited. You can delete the product attribute if it should not apply for routing purposes.| Field | Description |

|---|---|

| Product |

See product. The product you selected at the Products screen. The product code is separated from the product name by a hyphen (-). Display-only. |

| Attribute Code |

The Code identifying an attribute you can apply to a product. Display-only. |

| Description |

The description of the selected attribute. Display-only. |

| Data Type |

Indicates the type of data that can be defined through the selected attribute. Possible data types are:

Display-only. |

| Value |

Use this field to enter or select the value for the product attribute. If the Data Type is:

Required, except that a Boolean defaults to selected and is display-only. |

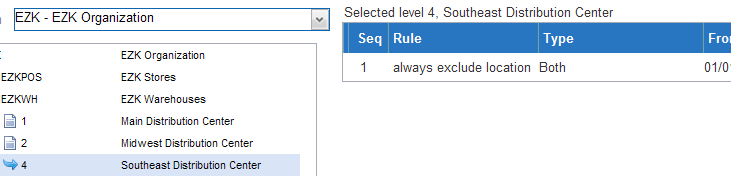

Probability Rules

Purpose: Use the Probability Rules screen to review or work with rules you can apply to the inventory information displayed in locate items search results or used for Routing Engine assignment, such as reducing the available quantity in a product location that has a high sell-through rate. From this screen, you can:

- review existing probability rules

- create a new rule

- select an existing rule to review the details on how it affects locate items results, or to change the rule

- delete a rule, provided it does not have existing details on how to affect locate items results

- advance to a window where you can review or work with calculations that you can include in probability rules

Used for the Routing Engine module.

How to assign rules? Use the Probability Location screen to assign probability rules and review the rules already assigned to locations.

Rules are not restricted to a single organization. You can assign rules to location types or locations in any organization.

Probable quantity rules: You use the Probable Quantity Rules screen rather than this screen to work with probable quantity rules, which update the probable quantity that a system, such as your ecommerce site, can use to estimate an item’s availability. For more information on probable quantity rules and calculation of the probable quantity, see:

- the Probable Quantity Rules screen

- the Probable Quantity Location screen

- the Inventory Quantity Export at the System screen

How to display this screen: Select Probability Rules from the Home Screen or from the Products Menu.

For more information: For a brief overview of probability rules, see Using Probability Rules; and for more details, see Probability Rule Overview.

Note:

Available if Use Routing Engine is selected at the Tenant screen. Only users with Probability Rules authority can display this screen. See the Role Wizard for more information.Options at this screen

| Option | Procedure |

|---|---|

| create a probability rule |

Enter a rule name in the Name field and click New to advance to the Probability Rule Wizard screen, where you can set up a rule. The name can be up to 40 positions, and can include spaces and special characters. For more information: See Probability Rule Wizard for instructions on setting up probability rules, including sample rules. |

| search for a probability rule |

Enter a full or partial rule name in the Name field at the top of the screen and click Search to restrict the search results to rules whose names contain your entry. Case? The rule name is case-sensitive for searching; for example, an entry of a does not match a rule that includes the word Add. |

| select a probability rule for maintenance |

Click the edit icon ( |

| review a probability rule |

Click a probability rule once to open the Browse Probability Rules window. |

| delete a probability rule |

Select the delete icon ( You can delete a rule only if there are no rule details and the rule has not been assigned to an organization, location type, or location. See the Probability Location screen for information on reviewing rule assignment. |

| review or work with calculations that can be included in probability rules |

Click Calc to advance to the Calculations window. |

Fields at this screen

| Field | Description |

|---|---|

| Name |

A description of the probability rule. The name can be up to 40 positions, and can include spaces and special characters. The rule name is case-sensitive for searching; for example, an entry of a does not match a rule that includes the word Add. |

| Results fields | |

| Name |

The description of an existing probability rule. |

| Edit |

Click the edit icon ( Note: If the Probability Rule Wizard screen is already open in another tab, you advance to that screen, where the previously-selected rule is displayed. |

| Delete |

Click the delete icon ( This option is available only if the rule has not been assigned to an organization, location type, or location. See the Probability Location screen for information on rule assignment. |

Calculations

Purpose: Use the Calculations window to review, create, or delete calculations that you can include in probability rules. Calculations allow you to add flexibility in how you present availability information in locate items search results or select a location for Routing Engine assignment. In order to include a calculation as part of a rule, you must first set it up at this window.