Use this screen to work with values that control the integration between Order Management System and Order Broker’s Order Broker and merchandise locator function. You can use this integration to:

• search for inventory across the enterprise

• automatically have backorders originating in Order Management System fulfilled in an external system, such as Xstore, and prevent selling out backorders unnecessarily

• use Order Management System to fulfill orders originating in a point of sale system, such as Xstore

• send orders from your Order Management System warehouse to a retail store location, where the customer can pick it up

Supplier Direct Fulfillment integration: The integration with Order Broker’s Supplier Direct Fulfillment module uses the OROB System (K50) and OROB Default Location (K51), but none of the other system control values on this screen.

For more information: See:

• the Order Broker Integration Overview for a a high-level discussion of the integration

• the Order Broker Integration for detailed information on integration with the Order Broker

• the Merchandise Locator API for detailed information on searching for items across the enterprise

• Order Broker Configuration for additional setup requirements

Additional system control values related to the Order Broker: See Order Broker Configuration for information on additional system control values that are not included on this screen.

Order Broker values:

• Use Merchandise Locator (I38)

• Merchandise Locator Distance Measurement (I39)

• Default Search Within Radius (I40)

• Order Broker Status Update Interval (K10)

• Order Broker Include Ship Complete Orders (K12)

• Order Broker Due Date Threshold (K11)

• Order Broker Include Coordinate Grouped Orders (K13)

• Order Broker Include Gift Orders (K14)

• OROB Default Location Code for Unfulfillable Orders (K56)

• Send Inventory by Warehouse to OROB (L06)

• Name in OROB for Point of Sale (L09)

• Send Held Orders to OROB (M18)

• Retain Backordered Lines Brokered to OROMS (K89)

• Order Type for Orders Brokered for Delivery (K91)

• Order Broker Error Batch Number (K90)

• Sold to Email Update for Orders Brokered to OROMS (K96)

• Order Type for Retail Pickup Orders Brokered to OROMS (K92)

• Order Broker Hold Reason (Cancel) (L02)

• Sold to Address Update for Orders Brokered to OROMS (K97)

• Order Broker Source Code (K93)

• Hold Reason for Errored Ship for Pickup Orders (L10)

• Ship Complete for Orders Brokered to OROMS (L01)

• Order Broker Payment Type (K98)

• Order Broker Price Override (K95)

• Gift Flag for Orders Brokered to OROMS (L03)

• Calculate Freight for Store Pickup Orders (L32)

• Re-Polling for Orders Brokered to OROMS (L04)

• Store Pickup Order Type (L33)

• Cancel Reason (Rejected Store Pickup Orders) (G11)

• Payment at POS for Ship for Pickup Orders (L60)

• Create Separate Picks for Ship for Pickup Orders (L89)

• Cancel Reason (Pick In) (L86)

• Payment at POS for Store Pickup (M16)

• Suppress Returns for Retail Pickup/Delivery (L88)

• OROB Item Category Value (M54)

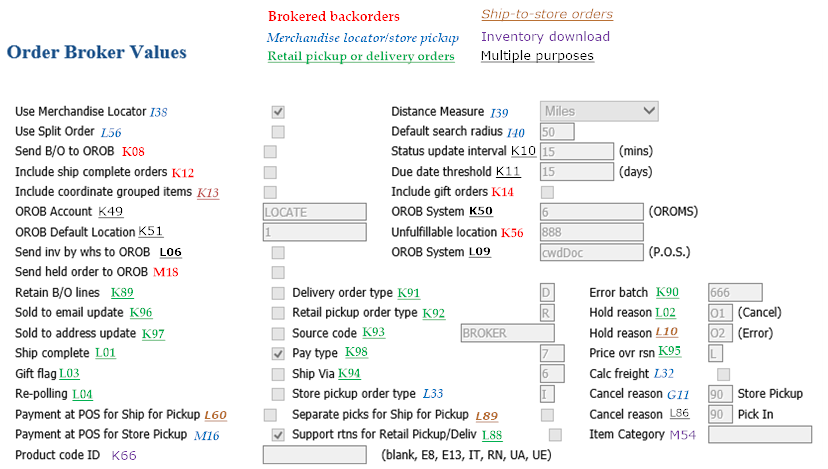

Sample screen:

Order Broker Fulfillment values:

Select Order Broker Fulfillment on the Order Broker Values screen to display the system control values related to using Order Broker for fulfillment assignment.

• Use OROB for Fulfillment Assignment (M31)

• Use OROB for Ship for Pickup Fulfillment Assignment (M34)

• Originating Location to Pass to OROB (M32)

• Order Type for Delivery Orders Originating in OROMS (M33)

• Order Type for Retail Pickup Orders Originating in OROMS (M35)

Select this field to have the:

• Merch locator option available to advance to the Merchandise Locator Search Window (Searching for an Item). You can use this window to research an item’s availability in locations where the customer might be able to pick up the item.

• Store Pickup option available to advance to the Merchandise Locator Search Window (Store Pickup) if the Store Pickup Order Type (L33) specifies an order type. You can use this window to find a store location where the customer can pick up the items on the order. If you select a store location, the system converts the order to a store pickup order and sends it to Order Broker in order to notify the store location.

Leave this field unselected if you do not use the merchandise locator or store pickup options.

Merchandise Locator Distance Measurement (I39)

Defines the default unit of measurement for merchandise locator and store pickup searches. Set this field to:

• M = the distances entered at the Merchandise Locator Search Window (Searching for an Item) and Merchandise Locator Search Window (Store Pickup) are in miles

• K = the distances entered at the Merchandise Locator Search Window (Searching for an Item) and Merchandise Locator Search Window (Store Pickup)are in kilometers

The distances displayed at the Merchandise Locator Search Results Screen and the Store Pickup Search Results Screen also use this unit of measure.

Leave this field blank to have the distance of measure default to M (miles), or if you do not use the merchandise locator or store pickup options.

Select this system control value to have Order Management System send all brokered backorders on an order to Order Broker in a single SubmitOrder message.

Leave this field blank to send each backordered line separately.

Note:

• If this system control value is not selected:

- Order Management System does not support canceling individual lines on a store pickup order if, for example, the customer picks up one item on the order but declines to pick up another. See Receiving a Store Pickup Cancellation from Order Broker for a discussion.

- No freight charges are included in the SubmitOrder message to Order Broker.

• This system control value should not be selected if the Create Separate Picks for Ship for Pickup Orders (L89) system control value is selected.

About splitting orders:

• Required Setup for Splitting Orders

• Splitting Brokered Backorders but not Lines

• Splitting Brokered Backorder Lines

• If the Order or Line Splits After Initial Creation in Order Broker

• Status Updates to Order Broker

Required Setup for Splitting Orders

At the Preferences screen in Order Broker, set the Allow Split Order flag consistently with this system control value. Optionally, if you select the Allow Split Order flag in Order Broker, you can also select the Allow Split Line flag. See below for a discussion.

Splitting Brokered Backorders but not Lines

When Order Management System sends one or more brokered backorder lines to the Order Broker and the Allow Split Order flag is selected in Order Broker, but the Allow Split Line flag is not selected:

1. The Order Broker first looks for a single location that can fulfill the complete requested quantity of all submitted lines on the order.

2. If the Order Broker cannot find a single location that can fulfill the complete requested quantity of all lines, it looks for two or more locations that can each fulfill the complete requested quantity of the lines separately.

3. If it is not possible to assign all the order lines to fulfilling locations even by splitting the order and assigning the lines separately, the Order Broker assigns lines when possible to fulfilling locations and assigns each unfulfillable line to the unfulfillable location. In this situation, the unfulfillable order line returns to standard backorder processing in Order Management System.

Scenario |

Example |

Order with multiple items assigned to a single fulfilling location |

Order includes: • AB100: 1 unit • CD200: 2 units Possible locations that support shipment and are not excluded based on probability rules or distance: • store 10: - 2 units AB100 - 2 units CD200 • store 20: - 100 units AB100 - 1 unit CD200 Store 10 has sufficient inventory of both items, so the Order Broker assigns the entire order to this location. |

Order with multiple items assigned to multiple fulfilling locations |

Order includes: • EF300: 1 unit • GH400: 2 units Possible locations that support shipment and are not excluded based on probability rules or distance: • store 10: - 3 units EF300 - 1 unit GH400 • store 20: - 5 units GH400 (EF300 not stocked) Since there is no single location that has sufficient inventory of both items, the Order Broker assigns the first item (EF300) to store 10 and the second item (GH400) to store 20. |

One or more items on an order can be assigned to fulfilling location(s), but an item is unfulfillable |

Order includes: • IJ500: 1 unit • KL600: 3 units Possible locations that support shipment and are not excluded based on probability rules or distance: • store 10: - 50 units IJ500 - 1 unit KL600 • store 20: - 2 units IJ500 - 1 unit KL600 The Order Broker assigns the first item (IJ500) to location 10. Since there is no location that has sufficient inventory for KL600, the Order Broker assigns the item to the unfulfillable location; as a result, Order Management System returns the item to standard backorder processing. |

Splitting Brokered Backorder Lines

When Order Management System sends one or more brokered backorder lines to the Order Broker, and both the Allow Split Order flag and the Allow Split Line flag are selected in Order Broker:

1. The Order Broker first looks for a single location that can fulfill the complete requested quantity of all submitted lines on the order.

2. If the Order Broker cannot find a single location that can fulfill the complete requested quantity of all lines, it looks for two or more locations that can each fulfill the complete requested quantity of the lines separately.

3. If it is not possible to assign all the order lines to fulfilling locations even by splitting the order and assigning the lines separately, the Order Broker assigns lines when possible to fulfilling locations and looks for two or more locations that, among them, can fulfill the complete requested quantity of each line that cannot be completely assigned to a single location.

4. If it is not possible to completely assign an order line even by splitting the line across multiple locations, the Order Broker assigns each unfulfillable line to the unfulfillable location. In this situation, the unfulfillable order line returns to standard backorder processing in Order Management System.

Note: If a possible location supports backorders and stocks the item, the Order Broker assigns the entire quantity of the order line to that location rather than splitting the line.

Scenario |

Example |

An order line on a multi-line order can be fulfilled only by splitting |

An order includes 3 units of item AB100. Possible locations that support shipment, are not excluded based on probability rules or distance, but do not support backorders: • store 10: 2 units • store 20: 2 units The Order Broker assigns 2 units to location 10 and 1 unit to location 20. |

An order line on a multi-line order cannot be completely fulfilled even by splitting |

An order includes 5 units of item CD200. Possible locations that support shipment, are not excluded based on probability rules or distance, but do not support backorders: • store 10: 1 units • store 20: 3 units Since it is not possible to assign all 5 units even by splitting the line across locations, the Order Broker assigns the entire order line to the unfulfillable location; as a result, Order Management System returns the item to standard backorder processing. |

If the Order or Line Splits After Initial Creation in Order Broker

It is possible for a selected fulfilling location to reject an assigned order or order line if, for example, the available inventory for the item was overstated in Order Broker. In this situation, the Order Broker “reshops” the rejected order or line, attempting to find one or more possible fulfilling location(s).

Settings |

Example |

The Allow Split Order is selected, the Allow Split Line flag is not selected |

Single line rejected: An order is assigned to location 10: • AB100: 2 units • CD200: 1 unit Store 10 accepts the line for AB100, but rejects the line for CD200 because the item is not actually available. The Order Broker then assigns the line for CD200 to store 20, where 3 units are available. In this situation, Order Management System has two Order Broker records, both for store 10, when Order Broker initially accepts the order. After it receives a status inquiry response with the updated information, it updates the second Order Broker record with the new assignment of store 20. |

Both the Allow Split Order and Allow Split Line flags are selected |

Splitting the line after initial order creation: An order for 3 units of EF200 is assigned to store 20, but the location rejects the order because the requested quantity of the item is not actually available. The Order Broker next assigns the order line across: • store 30: 1 unit • store 40: 2 units In this situation, Order Management System has a single Order Broker record for store 20 and a quantity of 3 when Order Broker initially accepts the order. After it receives a status inquiry response with the updated information, Order Management System: • updates the first Order Broker record with a quantity of 1 and store 30 • creates a new Order Broker record with a quantity of 2 and store 40 A partial line quantity is unfulfillable after initial order creation: An order for 3 units of GH300 is initially assigned to: • store 60: 2 units • store 70: 1 unit Order Management System initially creates an Order Broker record for the 2 units in store 60 and the 1 unit in store 70. Store 70 rejects the order for 1 unit, and there are no additional locations that might fulfill this order line. The Order Broker assigns the 1 unit to the unfulfillable location. When Order Management System receives this update, it changes the status of the Order Broker record for the 1 unit to unfulfillable status and changes the location to the unfulfillable location. The single unit then returns to standard backorder processing once store 60 ships the 2 assigned units. |

Quantity not indicated in order transaction history messages: The order transaction history messages do not specify the quantity affected by the update; however, if you split orders and lines, the quantity affected may be less than the total order line quantity. For example, if the Order Broker splits an order line across two locations for fulfillment, and one of the locations fulfills its assigned quantity, the order transaction history message of Ln#: 2 Shipped by Broker does not indicate the fulfilled quantity.

For more information: See the overview in the Order Broker Operations Guide or online help for background on how the Order Broker assigns orders based on whether you use the option to split orders or lines.

Status Updates to Order Broker

When you select the split order setting, all status updates to Order Broker specify the line number to update. The message specifies the new status to apply, plus any other information such as the ship via and tracking number or cancel reason code and description, at the line level.

When you leave the split order setting unselected, all status updates to Order Broker specify information at the request ID level in Order Broker.

See the Order Status Update Cancel Request Message Sample (Brokered Backorder or Store Pickup) and the Order Status Update Sample (Retail Pickup, Delivery, or Ship-for-Pickup Orders) for examples and details.

Default Search Within Radius (I40)

Enter the number of miles or kilometers, depending on the Merchandise Locator Distance Measurement, to default at the Merchandise Locator Search Window (Searching for an Item) and Merchandise Locator Search Window (Store Pickup). This field indicates the distance from the customer’s location to search for item availability in stores and warehouses. You can override this default at the search window.

Leave this field blank if you do not want a value to default at the search window or if you do not use the merchandise locator or store pickup options.

Yes/no field: Select this field to have Order Management System submit backordered lines to the Order Broker for fulfillment (brokered backorders), and prevent backordered lines from selling out unnecessarily.

Important: This system control value must be selected if the Use OROB for Fulfillment Assignment (M31) system control value is selected or the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS.

BROKER process: The BROKER process in Working with Integration Layer Processes (IJCT) generates order, status inquiry, and status update request messages to the Order Broker, and receives the response messages.

Leave this field unselected if you are not using the Order Broker to fulfill backordered lines.

See Brokered Backorders for background.

Order Broker Status Update Interval (K10)

Number field: Enter the number of minutes that the BROKER process in Working with Integration Layer Processes (IJCT) should wait between sending status inquiry or update request messages to the Order Broker for an individual order. Typically, you would set this field to a short interval when you are first implementing the Order Broker integration, then to a longer interval for production purposes. The default interval is 60 minutes.

The BROKER process “wakes up” to begin the process of evaluating each order or order line periodically based on the Outbound delay time specified through Working with Integration Layer Processes (IJCT). For example, if the Outbound delay time is set to 600 seconds (10 minutes), the BROKER process waits 10 minutes after finishing its evaluation before it starts the evaluation process again and determines whether to send a status inquiry request for each individual order. In evaluating each order, it checks the latest time when it sent a status inquiry for that order and determines whether the Order Broker Status Update Interval (K10) has elapsed since then.

Example:

• The Outbound delay time for the BROKER process is set to 600 seconds (10 minutes).

• The Order Broker Status Update Interval (K10) is set to 60 minutes.

• The last time the BROKER process received a status update on an order was 8:02.

• You start the BROKER process at 8:50. It evaluates the order and determines that it is not yet eligible for a status inquiry, since less than 60 minutes have elapsed since its last inquiry.

• The BROKER process finishes evaluating orders at 8:55 and “wakes up” again at 9:05 based on the Outbound delay time of 10 minutes.

• This time, the order is eligible for a status inquiry, since it has been more than 60 minutes since the last inquiry.

Brokered backorder lines evaluated independently: The BROKER process evaluates each order line on a brokered backorder independently to determine when to send an inquiry request. For example, if one order broker line was last updated at 4:17, and another was last updated at 4:56, the process submits an inquiry request for the first line at 5:17 and the second at 5:56 based on a 60-minute status update interval.

This field does not control when the BROKER process sends:

• submit order requests for brokered backorders or store pickup orders, or status update requests when you cancel or sell out an item or order; there is no built-in delay for sending these requests.

• status inquiry requests for Order Broker records whose current status is In Transit, Intransit Polled, Received by Store, or Partial Fulfill; it sends these requests once a day based on the OROB_LIMITED_STATUS_BEG_TIME and OROB_LIMITED_STATUS_END_TIME properties in Working with Customer Properties (PROP) and the setting of the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value; see Setting the Daily Status Inquiry Time Window (all versions).

• fulfillment requests; it sends these messages periodically based on the Outbound delay time specified through Working with Integration Layer Processes (IJCT).

• status update requests: it sends these messages when the BROKER process “wakes up” after the Outbound delay time.

Leave this field blank if you are not using the Order Broker, or if you want to check for status updates every 60 minutes.

See the Order Broker Integration for background.

Order Broker Include Ship Complete Orders (K12)

Yes/no field: Select this field to have orders that are flagged to ship complete be eligible for submission to the Order Broker as brokered backorders if they meet all the other Rules for Submitting Backorders to the Order Broker.

You can review an order’s Ship complete setting at the Display Order Properties Screen.

Leave this field unselected if you want to exclude ship-complete orders from submission to the Order Broker.

See Brokered Backorders for background.

Order Broker Due Date Threshold (K11)

Number field: Enter the number of days you want to wait for receipt of a purchase order rather than using the Order Broker integration for:

• Brokered backorders: If there is an open purchase order that could fulfill the backordered item, and the purchase order is due within the number of days specified here or sooner, then the BROKER process does not send the submit order request message for the brokered backorder. See Brokering Items with Soldout Control Codes for a discussion on how this threshold applies to items flagged with soldout control codes.

• Retail pickup or delivery orders: If the Retain Backordered Lines Brokered to OROMS (K89) system control value is unselected, and you receive a retail pickup or delivery order request that includes a backordered item that is not expected within the number of days specified here, then the BROKER process sends a status update request message to the Order Broker rejecting the order.

Example: |

The Due Date Threshold system control value is set to 5 and: 1. There is an open purchase order for the backordered item due in 4 days. Result: • Outbound (brokered backorder) order: Order Management System does not submit the order line to the Order Broker. • Inbound (retail pickup or delivery) order: Order Management System accepts the order. 2. There is an open purchase order for the backordered item due in 6 days. Result: • Outbound (brokered backorder) order: Order Management System submits the order line to the Order Broker. • Inbound (retail pickup or delivery) order: Order Management System rejects the order. 3. There are 2 open purchase orders for the backordered item. One is due in 4 days, and the other is due in 10 days. After you run PO Layering, the full quantity of the first purchase order is accounted for on earlier orders. Result: • Outbound (brokered backorder) order: Order Management System submits the order line to the Order Broker, because based on PO layering, you do not expect receipt of an eligible purchase order for 10 days. • Inbound (retail pickup or delivery) order: Order Management System rejects the order. |

Leave this field set to zero if you are not using the Order Broker or if you would always like to send backordered order lines to the Order Broker for fulfillment (outbound orders) or accept retail pickup or delivery orders from the Order Broker (inbound orders), regardless of when you are expecting receipt of any purchase orders that might be able to fulfill them.

Note: Regardless of the setting of this system control value, drop ship items are always eligible to be retained for fulfillment through Order Management System.

See the Order Broker Integration for background.

Order Broker Include Coordinate Grouped Orders (K13)

Yes/no field: Select this field to have order lines assigned a Coordinate group code be eligible for submission to the Order Broker as brokered backorders if they meet all the other Rules for Submitting Backorders to the Order Broker.

You can use coordinate group codes to ensure that certain groups of items, such as set components, ship together.

Leave this field unselected if you want to exclude coordinate-grouped order lines from submission to the Order Broker.

Note: The setting of this system control value is ignored if the Use OROB for Fulfillment Assignment (M31) system control value is selected.

See Brokered Backorders for background.

Order Broker Include Gift Orders (K14)

Yes/no field: Select this field to have gift orders be eligible for submission to the Order Broker as brokered backorders if they meet all the other Rules for Submitting Backorders to the Order Broker.

You can review an order’s Gift flag at the Display Order Properties Screen. Flagging an order as a gift order prevents item prices from printing on the pick slip, and generates a gift acknowledgement to the customer sold-to. These options might not be supported when fulfilling the order through the Order Broker.

Leave this field blank if you want to exclude gift orders from submission to the Order Broker.

Note: The setting of this system control value is ignored if the Use OROB for Fulfillment Assignment (M31) system control value is selected.

See Brokered Backorders for background.

System name field: Use this field to specify the name of the Order Broker database, as specified in the account setting at the Order Broker Tenant screen. This account name is passed as the destination in Order Broker requests, Merchandise Locator Searching, and in Supplier Direct Fulfillment Processing.

This field is typically set to LOCATE. Although the account setting at the Tenant screen might be lowercase, the account entry here is not case-sensitive; LOCATE is the same as locate.

Note: This setting is at the Tenant screen in version 5.1 or later of Order Broker. Order Broker versions 4.0 through 5.0 use a setting in the locate-config.properties file on the Order Broker server, and prior versions of Order Broker determine the account setting from an entry in the rms_admin database.

Leave this field blank if you do not use the Order Broker Integration or Merchandise Locator Searching.

System name field: Use this field to specify the system code identifying your company in Order Broker for Order Broker requests and for Merchandise Locator Searching. The system code must be the same as your Order Management System company number.

This system code is passed as the system_cd in request messages to the Order Broker module, and in the LocateItems request message for Merchandise Locator Searching. For example, if your Order Management System company number is 2, you set this field to 2 (not 002; omit padding zeroes unless that is how you created the system code in Order Broker).

Order Broker uses this code not only to identify the requesting system, but also to identify the system product code for the item that is passed in the request message. This identification is important if the system product codes for an item vary in different systems that integrate with Order Broker, such as when you use a different item/SKU code in Order Management System than you use in CWStore.

Example: You call an item AB100 BLUE LRGE in Order Management System, and call the same item 6033 in CWStore. If the OROB System indicated here matches the system code identifying Order Management System in Order Broker, the Order Broker looks for a system product called AB100 BLUE LRGE. Then, if the Order Broker assigns the order to a CWStore location for fulfillment, it sends a notification to the store indicating that item 6033 is required.

Also used for the Supplier Direct Fulfillment integration: The integration with Order Broker’s Supplier Direct Fulfillment module also uses this system control value to determine the requesting_system_cd. See the Drop Ship Integration Values (H20).

Leave this field blank if you do not integrate with Order Broker.

System name field: Use this field to specify the location for:

• Periodic inventory updates and interactive item availability responses to Order Broker: If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this code is used as the location representing the Order Management System warehouse in Order Broker when creating or update a product location with current inventory information. When other external systems submit a merchandise locator request or order to Order Broker, the response message indicates that the product is stocked in this location.

• Brokered backorder requests to Order Broker: This code is passed as the originating location in the Order Broker request message for brokered backorders if the Use OROB for Fulfillment Assignment (M31) system control value is unselected, regardless of the setting of the Send Inventory by Warehouse to OROB (L06) system control value. If the Use OROB for Fulfillment Assignment (M31) system control value is selected, the system passes the location in the Originating Location to Pass to OROB (M32) system control value to Order Broker.

Order Broker uses this code to track history for the Order Broker request, and to avoid assigning an Order Broker order to the requesting location, even if Order Broker’s most current inventory information indicates that the requesting location has the requested item in stock. This code is passed as the requesting location_cd in the SubmitOrder request message.

• Store pickup requests to Order Broker: This code is passed as the originating location in the Order Broker request message for store pickup orders regardless of the setting of the Send Inventory by Warehouse to OROB (L06) system control value. Order Broker uses this code to track history for the Order Broker request. This code is passed as the requesting location_cd in the SubmitOrder request message.

• Merchandise locator requests to Order Broker: This code is passed as the requesting location_cd in the LocateItems request regardless of the setting of the Send Inventory by Warehouse to OROB (L06) system control value. See Merchandise Locator API for an overview.

• Fulfillment request to Order Broker: If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this code is passed as the requesting location_cd in the fulfillment request for newly assigned retail pickup or delivery orders assigned to Order Management System for fulfillment. See Order Broker Integration for an overview.

• Status update and inquiry requests to Order Broker: If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this code is passed as the requesting location_cd in the status inquiry and update requests for retail pickup, delivery, or ship-for-pickup orders. See Order Broker Integration for an overview.

• Ship-for-pickup requests to Order Broker:

- If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this code is passed as the requesting location_cd in the submit order request for ship-for-pickup orders.

- This code is always passed as the location_cd when submitting a ship-for-pickup order for a drop ship item. See Order Broker Integration for an overview.

Note: If you are generating ship-for-pickup orders for drop ship items, you need to specify a valid Order Broker location in this system control value; otherwise, Order Broker returns an error indicating that the requesting location is invalid.

Using a default requesting location relieves you of the requirement of setting up all of your allocatable warehouses as locations in Order Broker, even if you ordinarily ship merchandise from multiple warehouses.

For example, you might use Order Management System’s warehouse list functionality to reserve and ship orders from five warehouses; however, you can set this field to 1 in order to always specify a location_cd of 1 in a request message, so that you do not need to set up the additional four warehouses as locations in Order Broker.

The location code you enter here must be a valid location code in Order Broker in the system indicated in the OROB System (K50) system control value, and should be uppercase if it is not numeric. If you use Order Broker’s Product, Product Location, and Incremental Inventory Import Process, the process creates a product location record for each item in this location, provided the item is flagged as OROB eligible in Order Management System.

Also used for the Supplier Direct Fulfillment integration: The integration with Order Broker’s Supplier Direct Fulfillment module also uses this system control value to determine the requesting_location_cd for the CreateDSOrder message to send a drop ship purchase order to Order Broker. See the Drop Ship Integration Values (H20).

Leave this field blank if:

• you do not integrate Order Management System with Order Broker, or

• if you do not integrate with Order Broker’s Supplier Direct Fulfillment module, if you have the Send Inventory by Warehouse to OROB (L06) system control value selected, and if you:

- do not use the merchandise locator search, store pickup, or brokered backorder options in Order Management System, and

- have specified a OROB location for each warehouse that maps to a location in Order Broker

See the Order Broker Integration for background.

OROB Default Location Code for Unfulfillable Orders (K56)

System name field: Use this field to identify the Default Unfulfillable Location set up in Order Broker. Your entry here must match the Default Unfulfillable Location you have set up in Order Broker, which is where the Order Broker assigns order lines it cannot fulfill. When Order Management System receives a response from the Order Broker indicating that a brokered backorder is assigned to this location, it indicates that the Order Broker is unable to fulfill the order. In this case, Order Management System returns the order line to standard backorder and fulfillment processing.

Note: Prior to Order Broker 5.3, the Default Unfulfillable Location is labeled the Default Shipping Location at the Preferences screen.

Leave this field blank if you do not send brokered backorders to the Order Broker.

See Brokered Backorders for background.

Send Inventory by Warehouse to OROB (L06)

Yes/no field: Indicates whether:

• Order Broker’s Product, Product Location, and Incremental Inventory Import Process and Item Availability Updates should separate inventory information by warehouse, or aggregate information across warehouses and use the OROB Default Location (K51) as the location representing the distribution center in Order Management System.

• When polling for newly assigned retail pickup or delivery orders, to send a separate fulfillment request message to the Order Broker by warehouse, or to send a single request for the OROB Default Location (K51).

Note: The BROKER process polls for retail pickup or delivery orders only if you specify an order type in the Order Type for Orders Brokered for Delivery (K91) or in the Order Type for Retail Pickup Orders Brokered to OROMS (K92) system control value.

• When sending a status update or inquiry request, whether the requesting location is the OROB location for the warehouse shipping the order, or to specify the OROB Default Location (K51).

If this value is:

Selected = Order Management System sends:

• product location information for each OROB eligible item in each warehouse that has an OROB location specified.

• a separate fulfillment request message for each warehouse that has a OROB location specified. The requesting location code is the OROB location.

• a status update or inquiry request message identifying the warehouse’s OROB location as the requesting location.

Unselected = Order Management System sends:

• product location information for the OROB Default Location (K51), summing up information across all allocatable warehouses.

• a single fulfillment request message, using the OROB Default Location (K51) as the requesting location.

• a status update or inquiry request message identifying the OROB Default Location (K51) as the requesting location.

See Order Broker’s Product, Product Location, and Incremental Inventory Import Process and Retail Pickup (including Ship-for-Pickup) or Delivery Orders for more information and examples.

Name in OROB for Point of Sale (L09)

Code field: Use this code to identify the code representing your default point of sale system in Order Broker for ship-for-pickup or store pickup orders.

Important: Your entry here must be a valid system code in Order Broker and the case must match exactly.

Override: You can use the System Code specified for a Store Cross Reference to override the default system name. For example, if you use the Store Connect module for pickup orders in some store locations, but use a point-of-sale system for other locations that support ship-for-pickup orders, you might set this system control value to the code identifying your point-of-sale system, and enter the code for your Store Connect system for the Store Cross Reference records used for Store Connect locations. When submitting a store pickup or ship-for-pickup order to Order Broker, Order Management System uses the System Code, if any, from the Store Cross Reference record; otherwise, it uses the system code from this system control value.

Ship-for-pickup orders: If you specify a code here, the Store option is available at the Create One Time Ship To Address Screen in order entry, so that you can select the store where the customer wants to pick up a ship-for-pickup order. Otherwise, if this field is blank, you cannot create ship-for-pickup orders in order entry.

Store pickup orders: If you do not specify a code here or for the Store Cross Reference record, Order Management System cannot successfully submit a store pickup order to Order Broker.

Leave this field blank if you do not submit ship-for-pickup or store pickup orders to Order Broker.

See Ship-for-Pickup Orders and Store Pickup Orders for background.

Send Held Orders to OROB (M18)

Yes/no field: Indicates whether to submit backordered items to Order Broker for reservation and preliminary processing even if the order is held.

Important: If the Use OROB for Fulfillment Assignment (M31) system control value is selected or the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS, the recommended setting for this system control value is unselected.

Select this field to have Order Management System submit backordered items to Order Broker even if the order is still held, provided it is otherwise eligible based on the Rules for Submitting Backorders to the Order Broker. The SubmitOrder message to Order Broker indicates that the order is Under Review, and should not be shipped until the order’s Under Review flag is cleared.

You might use this setting to provide the location that fulfills a brokered backorder with the opportunity to reserve stock and begin order processing before the order is removed from hold.

Notifying Order Broker of a change: If this system control value is selected, Order Management System sends an order update to Order Broker whenever an order that includes a brokered backorder item changes from held to open, or vice versa:

• held order in Order Management System = Under Review flag selected in Order Broker

• open order in Order Management System = Under Review flag unselected in Order Broker

Important:

- Order Broker does not prevent an integrated system from fulfilling an order flagged as Under Review. The integrated system needs to check the setting of the Under Review flag to determine whether an order is eligible for fulfillment.

- If you select the Use OROB for Fulfillment Assignment (M31) system control value or set the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value to ALWAYS, it is recommended that you unselect the Send Held Orders to OROB (M18) system control value.

Tracking changes: Updates to the Under Review flag are not tracked through Working with Order Broker (WOBR) or at the Display Order Broker Details Screen; however, a message is displayed at the Display Order History Screen, and the initial setting and any changes are tracked in Order Broker under order status history. This information is displayed at the Order screen in Order Broker, under the History tab.

Preorders: This system control value also controls whether the PREORDER periodic function includes held orders. See Releasing Eligible Orders to Order Broker and Submitting the Pre-Order (Backorder Quantity Update) Notification (PREORDER Periodic Function) for more information.

Leave this field unselected if you do not want Order Management System to submit backordered items to Order Broker unless the order status is open:

• Order Management System does not submit brokered backorders to Order Broker if the order is created in held status.

Note: To prevent sending orders to Order Broker if they have failed authorization, you need to specify a hold reason code for each declined response code. See Defining Vendor Response Codes for more information.

• If you release an order from hold after initial creation, the order is not submitted to Order Broker unless you run the BROKER Periodic Function.

• Order Management System does not submit updates based on changes to the order’s status.

• If an order is held after initial creation of the order and of the Order Broker record, Order Management System does not send an order update message to Order Broker; the order is still eligible for fulfillment by the assigned fulfilling location unless you cancel the order, update the order in Order Broker, or notify the location.

Note: This setting applies to Brokered Backorders only. If the Payment at POS for Store Pickup (M16) system control value is unselected, similar rules apply to store pickup orders. See that system control value for more information.

Hold reason requirement: The system puts an order on hold for a declined authorization based on the hold reason code, if any, defined for the vendor response. If no hold reason is defined, the order does not go on hold and can be eligible to send to Order Broker even if this system control value is unselected. See Defining Vendor Response Codes for more information.

Retain Backordered Lines Brokered to OROMS (K89)

Yes/no field: Indicates whether to accept retail pickup or delivery orders assigned by the Order Broker even if any of the items are currently on backorder. If this value is:

Selected = Order Management System accepts retail pickup or delivery orders regardless of whether any of the items are fully or partially backordered.

Unselected = Order Management System accepts a retail pickup or delivery order that includes a backordered item only if the item is expected on a purchase order due within the Order Broker Due Date Threshold (K11).

Note: Regardless of the setting of this system control value, drop ship items are always eligible to be retained for fulfillment through Order Management System.

See the Order Broker Due Date Threshold (K11) system control value for a discussion and examples.

Order Type for Orders Brokered for Delivery (K91)

Code field: Use this field to indicate the order type to assign to orders received from the Order Broker with a delivery type of Delivery. These are orders that originated in an external system, such as Xstore, and were assigned to Order Management System through the Order Broker integration in order to ship them directly to the customer. Your entry must be a valid order type, as specified through Establishing Order Types (WOTY).

If you specify an order type both here and in the Order Type for Retail Pickup Orders Brokered to OROMS (K92), the BROKER process sends fulfillment request messages to Order Broker periodically to poll for newly assigned orders. Both order types must be specified, even if you fulfill only one type of these types of orders.

Note: This system control value is also used when notifying Order Broker to set the status of a ship-for-pickup order to intransit, so it must be populated if you process ship-for-pickup orders even if you do not process delivery orders.

Leave this field blank only if you do not process delivery, retail pickup, or ship-for-pickup orders with the Order Broker.

See Retail Pickup (including Ship-for-Pickup) or Delivery Orders for background.

Order Broker Error Batch Number (K90)

Number field: Use this field to indicate the batch number to assign to delivery or retail pickup orders received from the Order Broker if they are in error for any reason. If an order is in error and you do not specify a batch number here, the system assigns the order to the Default Batch for E-Commerce Orders in Error (G41).

Leave this field set to zero if you do not receive delivery or retail pickup orders from the Order Broker, or if you want to assign the orders to the Default Batch for E-Commerce Orders in Error (G41) if they are in error.

See Retail Pickup (including Ship-for-Pickup) or Delivery Orders for background.

Sold to Email Update for Orders Brokered to OROMS (K96)

Yes/no field: Use this field to indicate whether to update a customer’s email address based on the information received from the Order Broker for a delivery or retail pickup order:

Selected = Update an existing customer's email address at the customer sold-to level, and primary email address in the Customer Sold To Email table.

Unselected = Do not update an existing customer’s email address.

See Working with Customer Email Addresses for an overview on email addresses, and see Retail Pickup (including Ship-for-Pickup) or Delivery Orders for a process overview.

Note: Regardless of the setting of this system control value, email updates you receive in Order Management System on a retail pickup or delivery order do not update the associated customer record in Oracle Retail Customer Engagement when you use the Customer Engagement Customer Integration. As a result, the customer’s primary email address is overwritten if you retrieve the customer information from Oracle Retail Customer Engagement.

Order Type for Retail Pickup Orders Brokered to OROMS (K92)

Code field: Use this field to indicate the order type to assign to orders received from the Order Broker with a delivery type of Retail pickup. These are orders that originated in an external system, such as Xstore, and were assigned to Order Management System through the Order Broker integration in order to ship the merchandise to the originating store location. Your entry must be a valid order type, as specified through Establishing Order Types (WOTY).

If you specify an order type both here and in the Order Type for Orders Brokered for Delivery (K91), the BROKER process sends fulfillment request messages to Order Broker periodically to poll for newly assigned orders. Both order types must be specified, even if you fulfill only one type of these types of orders.

Note: This system control value is also used when notifying Order Broker to set the status of a ship-for-pickup order to intransit, so it must be populated if you process ship-for-pickup orders even if you do not process retail pickup orders.

Leave this field blank only if you do not process delivery, retail pickup, or ship-for-pickup orders with the Order Broker.

See Retail Pickup (including Ship-for-Pickup) or Delivery Orders for background.

Order Broker Hold Reason (Cancel) (L02)

Code field: Use this field to specify the hold reason code to apply when pick slip generation sends a status list or status inquiry request to the Order Broker to check the status of a retail pickup or delivery order, and the Order Broker indicates that the order has been canceled. In this situation, you also need to cancel the order in Order Management System.

Your entry must be a valid hold reason code, as specified through Establishing Order Hold Reason Codes (WOHR).

Leave this field blank if you do not receive retail pickup or delivery orders from the Order Broker.

Note: If you leave this field blank and Order Broker indicates that a retail pickup or delivery order is canceled in response to the status inquiry during pick slip generation, the system does not put the order on hold, and the pick slip generation job will continue to evaluate the order and submit status inquiry requests to Order Broker.

When you subsequently cancel the order line in Order Management System, no update is generated to Order Broker.

See Retail Pickup (including Ship-for-Pickup) or Delivery Orders for background.

Sold to Address Update for Orders Brokered to OROMS (K97)

Yes/no field: Use this field to indicate whether to update a customer’s name and address based on the information received from the Order Broker for a delivery or retail pickup order:

Selected = Update an existing customer's name and address at the customer sold-to level.

Unselected = Do not update an existing customer’s name and address.

Regardless of the setting of this system control value, the system always updates the customer’s day and evening phone numbers if they are provided in the fulfillment response message from the Order Broker.

See Retail Pickup (including Ship-for-Pickup) or Delivery Orders for background.

Note: Regardless of the setting of this system control value, name and address updates you receive in Order Management System on a retail pickup or delivery order do not update the associated customer record in Oracle Retail Customer Engagement when you use the Customer Engagement Customer Integration. As a result, the customer’s name and address are overwritten if you retrieve the customer information from Oracle Retail Customer Engagement.

Order Broker Source Code (K93)

Code field: Use this field to indicate the default source code to assign to retail pickup or delivery orders received from the Order Broker for fulfillment. The system uses the following hierarchy to determine the source code for these orders:

1. Use the source code, if any, passed in the fulfillment response message from the Order Broker; otherwise,

2. Use the Source code specified for the store location through Work with Store Cross Reference (WSCR); otherwise,

3. Use the source code specified in this system control value.

Your entry must be a valid source code. Typically, you would create a source code that is not eligible for free gifts, promotions, or other updates that could apply at order creation, and is not associated with an offer that could add any accompanying items. Also, you should confirm that your entry is not a restricted source code and is associated with a current offer. See Working with Source Codes (WSRC) for more information on setting up source codes.

Leave this field blank if you do not receive retail pickup or delivery orders from the Order Broker.

See Retail Pickup (including Ship-for-Pickup) or Delivery Orders for background.

Hold Reason for Errored Ship for Pickup Orders (L10)

Code field: Use this field to indicate the hold reason code to apply to a ship-for-pickup order if the Order Broker responds with an error when pick slip generation attempts to submit the order.

Your entry must be a valid hold reason code, as specified through Establishing Order Hold Reason Codes (WOHR).

Leave this field blank if you do not send ship-for-pickup orders to the Order Broker during pick slip generation.

The system submits a ship-for-pickup order to Order Broker during pick slip generation or drop ship purchase order processing in the following scenarios.

• When the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER, or

• When the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS but the Send B/O to OROB (K08) system control value is unselected.

See Ship-for-Pickup Orders for background.

Ship Complete for Orders Brokered to OROMS (L01)

Yes/no field: Use this field to indicate whether to have the system flag retail pickup or delivery orders sent from the Order Broker as Ship complete.

Selected (default) = Select the Ship complete flag when creating a retail pickup or delivery order from the Order Broker. The order is not eligible to have a pick slip printed until all items are reserved, resulting in a single shipment.

Unselected = Leave the Ship complete flag unselected when creating a retail pickup or delivery order. The order is eligible to have a pick slip printed as items on the order become reserved, possibly resulting in multiple shipments.

Note: This system control value is not currently implemented. When the message version is set to 5.0 or higher, the ship_complete setting passed in the fulfillments response message applies.

Selecting this field can help eliminate confusion for the system originating the order, since Order Management System does not send a status update message indicating that the order has been shipped until the entire order is shipped.

See Retail Pickup (including Ship-for-Pickup) or Delivery Orders for background.

Order Broker Payment Type (K98)

Number field: Use this field to specify the pay type to apply to retail pickup or delivery orders sent from the Order Broker.

Setup: This pay type is typically a “dummy” payment method, since the order is typically paid for at the originating store location. To simplify the order creation and fulfillment process, you can set up a payment method as a credit card that is not associated with an authorization or deposit service and has no other validation or requirements, such as leading digits, length, modulus check, and start or expiration date.

The pay type you enter here must be a valid pay type, as set up through Working with Pay Types (WPAY).

Order creation: When the system creates the retail pickup or delivery order in Order Management System, it uses the Description of this pay type as the Credit card # for the payment method on the order.

Restrictions: You cannot apply this pay type to an order in order entry or order maintenance; however, there is no restriction against applying this pay type through the generic order API.

Note: To avoid an error in order entry, do not set the Default Previous Pay Type in Order Entry (D64) system control value to ALL; otherwise, this pay type might default in order entry, although you cannot apply it to the order.

Leave this field blank if you do not receive retail pickup or delivery orders from the Order Broker.

See Retail Pickup (including Ship-for-Pickup) or Delivery Orders for background.

Order Broker Price Override (K95)

Code field: Use this field to specify the price override reason code to apply to order lines on retail pickup or delivery orders sent from the Order Broker.

A price override reason code is required in order to preserve the pricing passed from the Order Broker in the fulfillment response message and prevent Order Management System from repricing the order.

The price override reason code you enter here must be a valid code, as set up through Establishing Price Override Reason Codes (WPOR).

Leave this field blank if you do not receive retail pickup or delivery orders from the Order Broker.

See Retail Pickup (including Ship-for-Pickup) or Delivery Orders for background.

Gift Flag for Orders Brokered to OROMS (L03)

Yes/no field: Use this field to indicate whether to have the system flag retail pickup or delivery orders sent from the Order Broker as Gift orders.

Selected = Select the Gift flag when creating a retail pickup or delivery order from the Order Broker. Prices and dollar totals do not print on the pick slip. You might use this setting to eliminate confusion about possible discrepancies between the totals in Order Management System and in the originating system.

Unselected = Leave the Gift flag unselected when creating a retail pickup or delivery order.

Note: This system control value overrides the setting, if any, passed in the fulfillment response message.

See Retail Pickup (including Ship-for-Pickup) or Delivery Orders for background.

Number field: Use this field to indicate the default ship via code to apply to retail pickup or delivery orders sent from the Order Broker. The system applies this ship via to the order if no ship via code was passed in the fulfillment response message received from the Order Broker.

The ship via code you enter here must be a valid code, as set up through Working with Ship Via Codes (WVIA). Typically, you would select a ship via that does not add any additional freight charges to the order.

Leave this field blank if you do not receive retail pickup or delivery orders from the Order Broker.

If this system control value is blank, the Default Ship Via (A77) applies.

See Retail Pickup (including Ship-for-Pickup) or Delivery Orders for background.

Calculate Freight for Store Pickup Orders (L32)

Yes/no field: Indicates whether to calculate freight for store pickup orders you create in interactive order entry.

Select this field to have order entry use standard freight calculation based on the source code for store pickup orders.

Leave this field unselected to set the Calculate freight flag to N for store pickup orders, so that no freight applies.

Note:

• Additional freight: Regardless of the setting of this field, additional freight charges still apply if specified for the ship via.

• Order API: This field does not affect store pickup orders you receive through the order API. Even if this field is unselected, the order API still uses the regular freight calculation unless a freight amount is passed in the CWOrderIn message, or the calc_frt tag in the message is set to N.

Re-Polling for Orders Brokered to OROMS (L04)

Yes/no field: Indicates whether to send a status of polled to the Order Broker when a retail pickup or delivery order received in the fulfillment response message is in error.

Background: In Order Broker, the Require status update flag for a system (such as Order Management System) indicates:

• require a status update: the Order Broker continues to send retail pickup or delivery orders in the fulfillment response message until the system sends a status update of polled or accepted

• do not require status update: the Order Broker includes each new retail pickup or delivery order just once in the fulfillment response message

The setting of this system control value must match the setting of the Require status update flag in Order Broker:

Require status update flag in Order Broker |

Re-Polling for Orders Brokered to OROMS (L04) |

selected: the Order Broker continues to send a delivery or retail pickup order until it receives a status update of polled or accepted. |

selected: If a retail pickup or delivery order is in error, Order Management System sends a status update of polled; otherwise, if the order is created without error, Order Management System sends a status update of accepted. Either status update prevents the Order Broker from sending the same order again. |

unselected: the Order Broker sends a delivery or retail pickup order just once. |

unselected: Order Management System sends a status update of accepted only when the order is created without error. It does not send a status update of polled for orders that are initially in error. |

Important: If the Require status update flag is selected in Order Broker but this system control value is unselected, then the Order Broker would continue sending an order if there was an error in creating it in Order Management System, so the order could be created multiple times in Order Management System.

See Retail Pickup (including Ship-for-Pickup) or Delivery Orders for background.

Code field: Use this field to indicate the order type to apply to store pickup orders. If you enter a valid order type code and the Use Merchandise Locator (I38) system control value is also selected:

• the Store Pickup option is available at the Order Detail screen in order entry, enabling you to create store pickup orders

• the system assigns this order type to an order when it is flagged for store pickup, regardless of the order type entered or defaulted in order entry, or passed in the order_type attribute in the CWOrderIn message

• The BROKER process sends status inquiry messages for store pickup orders

Note: The system does not prevent you from assigning this order type to orders that do not specify a store location for store pickup.

Typically, the order type you specify here should not be flagged for online authorization. You can also use the order type to control the email notifications you send to the customer.

Your entry must be a valid order type, as specified through Establishing Order Types (WOTY).

Note: This order type must be flagged for Email notification so that the system generates the store pickup notification email. See Store Pickup Notifications for more information.

Leave this field blank if you are not creating store pickup orders.

Cancel Reason (Rejected Store Pickup Orders) (G11)

Code field: Use this field to indicate the cancel reason to use if:

• the assigned store location for a store pickup order rejects the order, or

• the Order Broker cannot create a store pickup order (for example, if the selected store location specified in the SubmitOrder request message is not a valid location in the Name in OROB for Point of Sale (L09))

• the customer cancels the order at a retail location, and the system receives the status update when it sends a periodic status inquiry request

Leave this field blank if you are not creating store pickup orders.

Note:

• If you leave this field blank when you use store pickup orders, any orders rejected by the selected location or by Order Broker will remain in open status.

• The Order Broker actually returns a status of unfulfillable when the order is rejected; however, the Order Broker status in Order Management System is rejected.

Cancel reason codes are defined in and validated against the Cancel Reason table. See Establishing Cancel Reason Codes (WCNR) for more information.

Payment at POS for Ship for Pickup Orders (L60)

Yes/no field: Select this field if the customer needs to pay for a ship-for-pickup order at the store. When this field is selected, the following rules apply to ship-for-pickup orders:

• The order must include only credit card payment methods; also, each pay type’s Card type must be set to Credit. No other card types, such as stored value cards, can be included. Otherwise:

- Order entry: you cannot complete entry of the order; instead, the screen displays the error Invalid pay type for ship for pickup order and you cannot complete creation of the order without correcting the payment method(s).

- Order API: the order is in error with an error reason of Non-CC on Ship for Pickup (error code SA).

• The payment method’s Suppress deposit and Suppress refund flags are set to Y.

• The payment method is authorized for $1.00 only during online authorization.

• Authorization is suppressed during pick slip generation.

• Order Management System sends the pick slip total to the Order Broker as the balance_due in the Submit Order message.

• Returns and refunds are restricted against ship-for-pickup orders, so that you cannot:

- process a return against an entire ship-for-pickup order or a line on a ship-for-pickup order in order maintenance, through the Work with Return Authorizations menu option or the CWRETURNIN message

- create a return authorization for a ship-for-pickup order through the Work with Return Authorizations menu option or the CWReturn message

- enter a negative additional charge against a ship-for-pickup order in order maintenance

- enter a line with a negative quantity on a ship-for-pickup order in order entry or order maintenance

- apply a discount to a closed order line on a ship-for-pickup order in order maintenance

Do restrictions apply to special orders? For the most part, the above restrictions do not apply to ship-for-pickup orders whose order type matches the Order Type for Special Orders (L15); however, the returns and refunds restrictions listed above apply to all ship-for-pickup orders, including special orders.

Leave this field unselected if you do not create ship-for-pickup orders, or if you do not collect payment for ship-for-pickup orders at the store.

Create Separate Picks for Ship for Pickup Orders (L89)

Purpose: Use this field to indicate whether to submit each item on a ship-for-pickup order separately to Order Broker when sending a ship-for-pickup order to Order Broker during pick slip generation or drop ship purchase order processing.

Yes/No field: Select this field to create a separate pick slip or drop ship purchase order for each line on a ship-for-pickup order. When Order Management System submits a ship-for-pickup order to Order Broker during pick slip generation or drop ship purchase order processing, splitting the picking documents by line creates a separate order in Order Broker for each line.

When are ship-for-pickup order sent to OROB during pick slip generation/drop ship purchase order creation? The system submits a ship-for-pickup order to Order Broker during pick slip generation or drop ship purchase order processing in the following scenarios.

• When the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER, or

• When the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS but the Send B/O to OROB (K08) system control value is unselected.

Why create separate orders in Oracle Retail Order Broker? Creating a separate order in Order Broker for each order line can prevent issues related to updating status at the line level if not all integrating systems can support line-level updates. For example, updates can be complicated if a customer picks up one item on the order and cancels the other item, or if staff discover, after pick slips are generated, that one of the items on the order is not available in the warehouse for shipment to the designated store.

Ship-for-pickup orders only: This system control value applies to all ship-for-pickup orders, regardless of whether the order type matches the Order Type for Special Orders (L15); however, it does not apply to any other order types fulfilled through the Order Broker integration.

Set items: Regardless of whether this system control value is selected, if the ship-for-pickup order includes a set item, the set master item is included on the same pick slip as one of the component items. See Entering Set Information (WSET) for background on sets.

Items OROB eligible? Splitting the pick slip or purchase order applies to items on ship-for-pickup orders regardless of whether the items are flagged as OROB eligible; however, Order Management System submits items to Order Broker only if the items are flagged as OROB eligible. Although the non-eligible items can still ship to the store, they are not tracked with the order in Order Broker.

If a single line splits across warehouses: It is possible for a single line to reserve and ship from more than warehouse if, for example, a partial quantity is available in two warehouses that are both in the same warehouse list. If it is a ship-for-pickup order, the pick slip for each warehouse generates a separate order in Order Broker, regardless of whether this system control value is selected.

Line number submitted to Order Broker: When this system control value is selected:

• For a warehouse shipment, the requesting system line number submitted to Order Broker (the line_item_no in the SubmitOrder message) consists of the warehouse code concatenated with the order detail sequence number. For example, if line 3 ships from warehouse 2, the requesting system line number is 2003. The locate_line_number in the CWPickOut message is the same as the requesting system line number, so that the fulfilling location can match the line numbers.

• For a drop shipment, the requesting system line number (the line_item_no in the SubmitOrder message) is from the order detail sequence number, and does not include the warehouse code. The locate_line_nbr in the CWPurchaseOrderOut message is also the order detail sequence number.

Voiding pick slips for ship-for-pickup orders: If this system control value is selected, then when you void pick slips for:

• Special ship-for-pickup orders through the Generic Pick In API (Shipments, Voids, and Backorders), the order is canceled in Order Management System, and Order Management System sends a status update to Order Broker indicating to cancel the order, specifying the Cancel Reason (Pick In) (L86).

• Regular ship-for-pickup orders through either the Generic Pick In API (Shipments, Voids, and Backorders) or through Reprinting and Voiding Pick Slips (WVRP or WSVP), the order is not canceled in Order Management System; however, Order Management System sends a status update to Order Broker indicating to cancel the order, without specifying a cancel reason. If you then reprint the pick slip, Order Management System submits a new order to Order Broker.

• Otherwise:

- If you void a special ship-for-pickup order through any other means than the generic pick in API, no update is sent to Order Broker.

- Similarly, if you void a regular ship -to-store order and this system control value is not selected, no update is sent.

- If, after voiding the pick slip, you then cancel the item or order, Order Management System sends an update to Order Broker indicating to cancel the order, specifying the cancel reason you enter.

Note: Order Management System needs to communicate with Order Broker when you void a pick slip for a ship-for-pickup order if this system control value is selected, so an error occurs if communication is down or Order Broker is unavailable. For example, if Order Management System cannot communicate with Order Broker when you attempt to void a pick slip through Reprinting and Voiding Pick Slips (WVRP or WSVP), the screen displays a message: Cannot void pick - OROB unavailable.

Important: When this system control value is selected, the Use Split Order (L56) system control value must be unselected; otherwise, you will be unable to send status updates from Order Management System to Order Broker.

Leave this field unselected if you want to submit a single order to Order Broker for each pick slip or drop ship purchase order, even if the picking document has multiple lines.

For more information: See Ship-for-Pickup Orders for background.

Code field: Use this field to specify the cancel reason code to use when you void a pick slip for a retail pickup, delivery, or special ship-for-pickup order through the generic pick in API.

Voiding a pick slip: If you enter a cancel reason in this field, when the Generic Pick In API (Shipments, Voids, and Backorders) processes a void or void/unreserve for a ship-for-pickup order whose order type matches the Order Type for Special Orders (L15) or for a retail pickup or delivery order, the system cancels the order line using the cancel reason specified here. If this is the only line on the order, then the entire order is canceled using this cancel reason.

The transaction_type in the CWPickIn XML Message indicates whether to process a void (V) or a void/unreserve (U). See Sample Pick In XML Messages for examples. Since both a void and a void/unreserve result in canceling the order line based on this system control value, there is no functional difference between the two transaction types.

Partial backorder? This system control value does not enable you to process a partial backorder through the generic pick in API. The only way that this system control value applies when the CWPickIn message has a transaction_type of B is if all pick detail lines are included in the CWPickIn message with a shipped quantity of zero; so, in this case, a partial backorder is the same as a void, because the total quantities of all pick detail lines are voided and the order lines canceled. See Sample Pick In XML Messages for an example of a partial backorder message.

Updated status sent to Order Broker: Depending on the type of order:

• special ship-for-pickup: Order Management System sends a status update indicating that the order is canceled.

• retail pickup or delivery: Unless Order Broker indicates that the order is already canceled, Order Management System sends a status update indicating that the order is rejected. In this case:

- if Order Broker is configured to “reshop” the order and there are any other possible fulfilling locations, the Order Broker reassigns the order to the next possible location based on the fulfillment rules set up in Order Broker, and the order returns to new order status.

- if Order Broker is not configured to “reshop” the order, or if there are no other possible fulfilling locations, the order is assigned to the OROB Default Location Code for Unfulfillable Orders (K56), and the order status is unfulfillable.

The cancel reason code and description are included in the status update message.

If you use order maintenance: If you cancel a retail pickup or delivery order in order maintenance, it sends Order Broker a status update rejecting the order as described above; however, the status update includes the cancel reason entered in order maintenance.

Void/reprint menu option: This system control value does not apply when you void pick slips through the Reprinting and Voiding Pick Slips (WVRP or WSVP) menu options. Retail pickup, delivery, and special ship-for-pickup orders are automatically canceled only when you use the Generic Pick In API (Shipments, Voids, and Backorders).

Voiding pick slips for regular ship-for-pickup orders: If the Create Separate Picks for Ship for Pickup Orders (L89) system control value is selected, then when you void pick slips for regular (not special) ship-for-pickup orders, the system sends a status update to cancel the Order Broker order for each order line, while the order remains option in Order Management System. No cancel reason is sent. Then, if you generate any new pick slips for the ship-for-pickup order, these pick slips create new orders in Order Broker. This process occurs regardless of whether you void the pick slips through either the Generic Pick In API (Shipments, Voids, and Backorders) or through Reprinting and Voiding Pick Slips (WVRP or WSVP).

Other Order Broker delivery types? The cancel reason specified here does not apply to any other types of orders fulfilled through integration with the Order Broker, such as brokered backorders, store pickup orders, or ship-for-pickup orders that do not match the Order Type for Special Orders (L15).

Cancel reason codes are defined in and validated against the Cancel Reason table. See Establishing Cancel Reason Codes (WCNR) for more information.

Leave this field blank if you do not want to automatically cancel retail pickup, delivery, or special ship-for-pickup orders when you void their pick slips through the Generic Pick In API (Shipments, Voids, and Backorders). In this case, you need to use order maintenance if you need to cancel these orders.

Payment at POS for Store Pickup (M16)

Yes/No field:

• Select this field to authorize store pickup orders for verification only. WIth this setting:

- the payment method on a store pickup order is authorized for $1.00

- the Suppress deposit flag is set to Y, so that the deposit is not processed in Order Management System when the order is billed

- the balance_due specified in the SubmitOrder message is equal to the order total

• Leave this field unselected to authorize and bill store pickup orders in Order Management System. With this setting:

- the payment method on a store pickup order is authorized for the full amount

- the Suppress deposit flag is set to N, so that the deposit is processed in Order Management System when the order is billed

- the balance_due specified in the SubmitOrder message is zero

Note: For store pickup orders, this system control value overrides the settings of the Online Auth Verification Only (I96) and Authorize Full Amount During Order Entry (G99) system control values.

Under Review?

Order Management System submits a store pickup order to Order Broker regardless of whether the order is held; however, if the order is held and this system control value is unselected, Order Management System submits the order to Order Broker with the Under Review flag selected. This setting indicates that the order should not be picked up until the Under Review flag is cleared, because Order Management System needs to be able to collect payment, but enables the store associates with the opportunity to reserve the inventory and prepare the order in the meantime.

If the order is not held, or if this system control value is selected, Order Management System does not select the Under Review flag when submitting the order, so the order is eligible for pickup.

You might use this setting to provide the location that fulfills a store pickup order with the opportunity to reserve stock and begin order processing before the order is removed from hold.

Notifying Order Broker of a change: If this system control value is unselected, Order Management System sends an order update to Order Broker whenever a store pickup order changes from held to open, clearing the Under Review setting.

Important: Order Broker does not prevent an integrated system from letting a customer pick up an order that is flagged as Under Review. The integrated system needs to check the setting of the Under Review flag to determine whether an order is eligible for pickup.