Order Broker: Integration with the Routing Engine module in Order Broker supports fulfilling orders across the enterprise.

Use the Order Broker integration for the following:

• brokered backorders: Automatically send backordered lines to the Routing Engine module in Order Broker, so the orders can be assigned to locations for fulfillment.

• If the Use OROB for Fulfillment Assignment (M31) system control value is selected, the system bypasses reservation in order to send all eligible items to Order Broker for fulfillment assignment, even if the item is available in the warehouse. In this situation, the fulfilling location may be a store location or an Order Management System warehouse.

• If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS, the system bypasses reservation in order to send eligible items on a ship-for-pickup order to Order Broker for fulfillment assignment. In this situation, the fulfilling location may be a store location or an Order Management System warehouse.

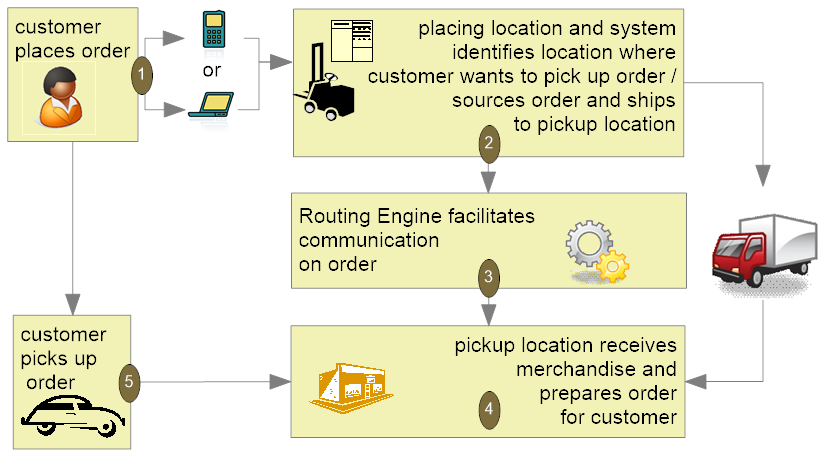

• receive retail pickup (including ship-for-pickup) or delivery orders from Order Broker: Receive and fulfill orders in Order Management System. If the order is a retail pickup order, Order Management System sends the merchandise to the customer’s selected store for pickup. If the order is a delivery order, Order Management System ships the merchandise to the customer’s ship-to address. Typically, retail pickup and delivery orders originated in an external retail location. In addition:

• If the Use OROB for Fulfillment Assignment (M31) system control value is selected, Order Broker may send a delivery order to Order Management System that originated as a brokered backorder in Order Management System. In this situation, Order Broker determined that an Order Management System warehouse was the best location to fulfill the order.

• If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS, Order Broker may send a retail pickup order to Order Management System that originated as a ship-for-pickup order in Order Management System. In this situation, Order Broker determined that an Order Management System warehouse was the best location to fulfill the order.

• send ship-for-pickup orders during pick slip generation/drop ship processing to Order Broker: If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER, ship orders to an external retail location for customer pickup if the merchandise is not already available at that location.

• send store pickup orders to Order Broker: Notify an external retail location that has inventory available that a customer will pick up an order.

Version compatibility: Fulfillment assignment and ship-for-pickup functionality is available in release 16.0 or higher of Order Management System and release 16.0 or higher of Order Broker. Also, in order to use ship-for-pickup processing, you must select the Enable Ship For Pickup option on the Organization window in Order Broker. Once you enable ship for pickup, the Organization window in Order Broker displays the Ship for Pickup Enabled Date, and you cannot deselect this option.

An OROB_MESSAGE_VERSION of 16.0 or higher is required to use the Ship-for-Pickup Orders integration with Order Broker.

For more information: See:

• Order Broker Integration Overview for general background on integration between Order Broker and Order Management System.

• Order Broker Configuration for required setup in Order Management System.

• the Order Broker Operations Guide for details on each request and response message, as well as details on logging and troubleshooting in Order Broker.

• the Order Broker online help for step-by-step instructions on populating the Order Broker database and on scheduling item and inventory imports.

For information on Order Broker processing in Order Management System, see:

• Retail Pickup (including Ship-for-Pickup) or Delivery Orders

• Troubleshooting the Order Broker Integration

• Sample Order Broker Messages

• Order Broker Status Summary Table

• Order Broker Originating Location, Fulfilling Location, and Pickup Location

• Working with Order Broker (WOBR)

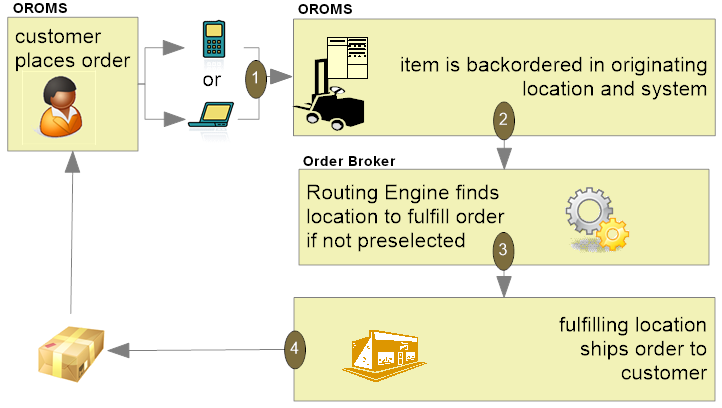

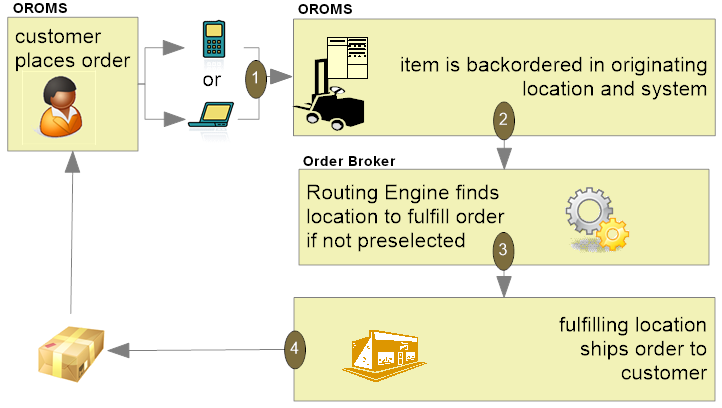

Purpose: If the Send B/O to OROB (K08) system control value is selected, you can use the Order Broker Integration to send backordered order lines to Order Broker for fulfillment.

• If the Use OROB for Fulfillment Assignment (M31) system control value is unselected, the system sends eligible backordered items to Order Broker for fulfillment. Order Broker will choose the best store location to fulfill and ship the item to the customer. Items that are in stock follow normal reservation and fulfillment processing.

• If the Use OROB for Fulfillment Assignment (M31) system control value is selected, the system bypasses reservation and places all eligible items on backorder, even if the item is available in an Order Management System warehouse. Order Broker will choose the best store location or Order Management System location to fulfill and ship the item to the customer.

• If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS, the system bypasses reservation in order to send eligible items on a ship-for-pickup order to Order Broker for fulfillment assignment. In this situation, the fulfilling location may be a store location or an Order Management System warehouse and the merchandise is shipped to the customer’s selected store for pickup. See Creating a Ship-for-Pickup Order in Order Management System for more information on how to create a ship-for-pickup order.

Note: If the item is flagged as a active PO item the system does not submit it to Order Broker for fulfillment using the standard process described here; instead, it uses the process described under Enterprise Order Integration (Future Receipts and Active PO/Pre-Order Processing).

When using Order Broker for fulfillment assignment, the fulfilling location can be a store location or an OROMS warehouse location. In addition, for ship-for-pickup orders, the fulfilling location ships the order to the customer’s selected store for pickup.

In this topic:

• Brokered Backorder Processing Overview

• Brokered Backorder Fulfillment: Initial Order Creation

• Fulfillment Process: After Order Creation and Status Updates

• Rules for Submitting Backorders to Order Broker

• Brokering Items with Soldout Control Codes

• Things to Note About Brokered Backorders

Brokered Backorder Processing Overview

Order Broker assignment: Assigning a backordered item to Order Broker can occur through:

• order entry or order API: When you create an order that includes a backordered line, Order Management System assigns the line, if eligible, to Order Broker for fulfillment, and withholds it from normal fulfillment processing within Order Management System.

Note:

• If the Use OROB for Fulfillment Assignment (M31) system control value is selected, the system bypasses reservation for all eligible items on an order and places them on backorder so that Order Broker can determine the fulfilling location.

• If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS, the system bypasses reservation for all eligible items on a ship-for-pickup order and places them on backorder so that Order Broker can determine the fulfilling location.

• batch process: A periodic function finds eligible backordered lines and assigns them to Order Broker.

Eligibility rules: Order Management System determines whether an order line is eligible for Order Broker fulfillment based on certain basic criteria, such as whether it is fully backordered and authorized; also, you can use related system control values to further restrict Order Broker assignment based on your business rules, such as omitting items you are due to receive soon on open purchase orders. Also, the item must be flagged as OROB eligible. See Rules for Submitting Backorders to Order Broker for details.

If the authorization for the order line has expired, the system obtains a new authorization.

Does each line create a separate order in Order Broker? Each eligible backordered line on an order is sent to Order Broker:

• as a separate order if the Use Split Order (L56) system control value is unselected. In this case, the fulfillment of each line is tracked individually. Order Broker does not attempt to assign multiple order lines from the same fulfilling location.

• as part of a single order if the Use Split Order (L56) system control value is selected. In this case, Order Broker attempts to assign all lines on the same order to the same fulfilling location; however, it notifies Order Management System about multiple assigned fulfilling locations if the order or lines are split. If a single backordered item is unfulfillable through Order Broker, that line returns to standard backorder processing, but additional lines on the order can still be fulfilled through Order Broker.

What information is sent to Order Broker? Order Management System sends the following information to Order Broker:

• sold-to and ship-to customers’ names and addresses.

• details on the requested item.

It does not send payment information, although only fully paid and authorized items are eligible for Order Broker fulfillment. If the Payment at POS for Ship for Pickup Orders (L60) system control value is selected, ship-for-pickup orders are authorized for verification only and payment is collected when the customer picks up the items at the store.

If the authorization for an order line has expired, the system obtains a new authorization.

For more information on the information sent to Order Broker, see Sample Order Broker Messages.

Brokered Backorder Fulfillment: Initial Order Creation

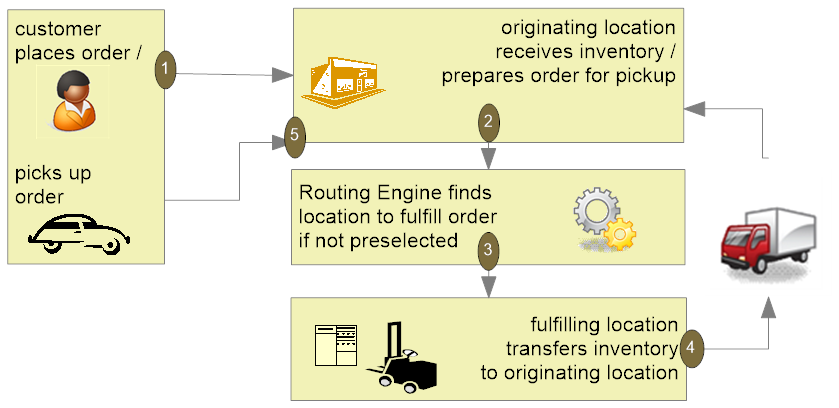

1. |

The process begins when you create an order in Order Management System. If the Send B/O to OROB (K08) system control value is selected, the system sends eligible backordered items to Order Broker to determine the fulfilling location. In addition: • If the Use OROB for Fulfillment Assignment (M31) system control value is selected, the system bypasses reservation and places all eligible items on backorder, even if the item is available in an Order Management System warehouse, in order to have Order Broker determine the fulfilling location. • If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS, the system bypasses reservation and places all eligible items on a ship-for-pickup order on backorder, even if the item is available in an Order Management System warehouse, in order to have Order Broker determine the fulfilling location. The order creation can occur through interactive order entry, batch order entry, or the order API. You can also use the BROKER periodic function to submit existing backordered lines to the Order Broker for fulfillment; see Additional Order Broker Setup in Order Management System for more information. |

2. |

If the order line meets the Rules for Submitting Backorders to Order Broker, the BROKER_ORD process in Order Management System generates a request message to Order Broker and creates an Order Broker record. Note: Order lines that meet the Rules for Submitting Backorders to Order Broker do not sell out initially, even if the items are flagged with soldout control codes. See Brokering Items with Soldout Control Codes for more information. If the order includes multiple backordered lines and the Use Split Order (L56) system control value is selected, the request message includes all eligible backordered lines; otherwise, each backordered item is submitted as a separate order. Each Order Broker record has a status of R (ready) at creation. Also, the order line is updated to restrict it from standard backorder processing in Order Management System: • the Drop ship flag is set to D. • the Printed quantity is updated to the ordered quantity. • An order line that is assigned to Order Broker for fulfillment displays a status of OBR in standard order inquiry. • the quantity to be brokered does not update the Backordered quantity for the Item Warehouse. • if the Use OROB for Fulfillment Assignment (M31) system control value is selected, the Bypass reservation flag is selected with a Backorder reason of Reservation bypassed indicating the brokered backorder was created for fulfillment assignment. • if the order is a ship-for-pickup order sent for fulfillment assignment, the Bypass reservation flag is selected with a Backorder reason of Reservation bypassed indicating the brokered backorder was created for fulfillment assignment. Note: Order Broker status is not displayed in Streamlined Order Inquiry (DORI). |

3. |

If the BROKER_ORD process in Working with Integration Layer Processes (IJCT) is active, it immediately generates the submit order request message to Order Broker to request order creation and assignment in Order Broker. At this time, it also changes each Order Broker record’s status to W (waiting) and creates an Order Broker History record for each line to track the order submission (A - Send Order Request). See the Brokered Backorder (Delivery or ShipForPickup) Submit Order Request Message Sample. Note: Although the BROKER_ORD process generates the submit order requests (and cancellation requests, if needed), the BROKER process handles other requests to Order Broker. |

4. |

The Routing Engine module in Order Broker receives the submit order message. If Order Management System sent each line separately, Order Broker creates each order line as a separate order in its database; otherwise, if you use the split order option, Order Broker creates a single order including all of the order lines that were eligible for submission as brokered backorders. Order Broker assigns each order or line to a location for fulfillment based on inventory availability and the business rules you have defined in Order Broker. At this point, the order status in the Order Broker database is new_order. |

5. |

Order Broker sends a response message to Order Management System indicating each assigned fulfilling location and the unique request ID it uses to identify each order. See the Submit Order Response Message Sample. Note: The message version is specified in the Order Broker Properties; this property must be set to 16.0 or higher in order to use brokered backorders for fulfillment assignment and to use ship-for-pickup processing. |

6. |

If Order Broker successfully created an order and assigned it to one or more fulfilling locations, Order Management System: • updates each Order Broker record with: • the fulfilling location, using the description set up through the Work with Store Cross Reference (WSCR) option. • the request ID. • a status of A (acknowledged). • writes an Order Transaction History message indicating that the order line was acknowledged by Order Broker (for example, Ln#: 2 Acknowledged by Broker). • creates an Order Broker History record (B - Receive Order Response). |

Split line? If the Allow Split Line? preference in Order Broker is selected, Order Broker might split the quantity of a single brokered backorder line across more than one fulfilling location. For example, you create an order for item AB100 with a quantity of 10. There is no single location that has a quantity of 10 available. Order Broker assigns 8 units to location 100, and 2 units to location 200.

Order Broker splits order lines or line quantities only if you have selected the Allow Split Order? and Allow Split Line? preferences in Order Broker, and if there is not a single location that can fulfill the entire order or line quantity. See the Use Split Order (L56) system control value for examples, and see the Order Broker Operations Guide or online help for background.

If Order Management System is the fulfilling location: If the Use OROB for Fulfillment Assignment (M31) system control value is selected or the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS, Order Broker may determine that a warehouse in Order Management System is the best location to fulfill the order, or some portion of the order. In this situation:

• Order Broker assigns the Order Management System location to the order in Order Broker as the Fulfilling location.

• At defined intervals, the BROKER process in Work with Integration Layer Processes (IJCT) periodically sends a fulfillments request message to Order Broker to poll for newly assigned orders (those whose Fulfilling location is an Order Management System location).

• When the BROKER process receives the order in the fulfillments response message:

• If the original order is not a ship-for-pickup order, it creates a new delivery order and assigns the order type defined in the Order Type for Delivery Orders Originating in OROMS (M33) system control value to the order.

• If the original order is a ship-for-pickup order, it creates a new retail pickup order and assigns the order type defined in the Order Type for Retail Pickup Orders Originating in OROMS (M35) system control value to the order.

• In order to tie the originating order (the original order sent to Order Broker for fulfillment assignment) with the new fulfilling order (the delivery or retail pickup order created to fulfill the original order), Order Management System:

• stores the originating order number in the E-commerce order number field in the Order Header Extended table for the newly created sourcing order. For example, the system updates the E-commerce order number with ORIG#: 9999-001, where ORIG#: indicates the order has been created as a result of OROB fulfillment assignment, 9999 is the order number, and 001 is the ship-to number.

• assigns the Request ID defined for the originating order to the newly created sourcing order.

See Retail Pickup (including Ship-for-Pickup) or Delivery Orders for more information on how Order Management System processes a delivery or retail pickup order.

If the assigned fulfilling location rejects the order: The location assigned to fulfill an order or line can reject it if, for example, it does not have sufficient inventory. In this situation, Order Broker uses the rules set up at the Preferences screen in Order Broker to select another location to fulfill the order. If the location where the order is currently assigned changes, Order Management System updates this information the next time it sends a status inquiry to Order Broker, typically through pick slip generation, and receives the new information in the response.

Note: An order normally remains in Rejected status in Order Broker only for a moment. If for any reason Order Broker receives a status inquiry request when the order’s status is Rejected, Order Management System does not update the order until the next time it sends a periodic status inquiry.

What if Order Broker cannot find a location to fulfill the order or line? In some cases, Order Broker cannot assign an order to a location because there are no locations with sufficient inventory that are eligible based on the business rules set up in Order Broker at the Preferences screen. In this situation, Order Broker assigns the order to the Default Unfulfillable Location specified in Order Broker, which should match the setting of the OROB Default Location Code for Unfulfillable Orders (K56) system control value. When Order Management System receives a response message indicating that the order was assigned to the unfulfillable location and has a status of Unfulfillable, it:

• Clears the Drop ship flag and the Printed quantity on the Order Detail line.

• If the Use OROB for Fulfillment Assignment (M31) system control value is selected or the original order is a ship-for-pickup order, unselects the Bypass reservation flag and updates the Backorder reason to Not enough avail in whse.

• Changes the status of the Order Broker record to U (unfulfillable).

• Writes an Order Transaction History record (for example, Ln#: 2 Unfulfillable by Broker).

• Returns the line to standard backorder or soldout processing, including updating the Backorder quantity for the Item Warehouse and updating the PO Layering record.

An order might be flagged as unfulfillable when Order Broker first receives the request message, or after one or more locations have rejected the order for fulfillment; in this case, Order Management System receives notification the next time it sends a periodic status inquiry, as described below.

Notifying the customer of fulfillment assignment through Order Broker: The order confirmation email indicate a status of Store Ship for order lines assigned to Order Broker. See the Order Confirmation Email Sample and Contents for more information.

Fulfillment Process: After Order Creation and Status Updates

Status list inquiry request and response process: The BROKER process in Working with Integration Layer Processes (IJCT) sends periodic status list inquiry requests to Order Broker. You use the Order Broker Status Update Interval (K10) system control value to define how many minutes Order Management System should wait before sending status inquiry requests.

If status has not changed: Once the order line is in Accepted status, Order Management System does not write a history record for the status list inquiry response as long as the record remains in this status.

Activity |

Status in OROB |

Status in OROMS |

Updates to Order Broker and Order Transaction History |

|---|---|---|---|

Order Management System sends the submit order message to Order Broker and restricts the order line from standard processing in Order Management System by setting the Drop ship flag and the Printed quantity. |

not yet created |

Waiting (W) |

• creates an Order Broker History record to track the order submission (A - Send Order Request) |

Order Management System receives the submit order response from Order Broker |

new_order |

Acknowledged (K) |

If there is a single fulfilling location: • creates an Order Broker History record to track the response (B - Receive Order Response) • updates the Order Broker record with the assigned fulfilling location • writes an Order Transaction History message (for example, Ln#: 1 Acknowledged by Broker) Otherwise, if there are multiple fulfilling locations, Order Management System sends a status inquiry request to Order Broker and performs the above activities when it receives the response. |

Polling: Each fulfilling location is responsible for polling Order Broker periodically to check for new orders. Once Order Broker receives a polling request from a location, it sends a polling response, listing the details of all new orders assigned to the location for fulfillment. |

polled |

Polled (P) (after receiving status inquiry response) |

• creates an Order Broker History record (D - Receive Status Response) • writes an Order Transaction History message (for example, Ln#: 1 Polled by Broker) |

Order accepted? If the assigned location can fulfill the order or line, it sends a status update message accepting the order or line to Order Broker. |

accepted |

Accepted (A) (after receiving status inquiry response) |

• creates an Order Broker History record (D - Receive Status Response) • writes an Order Transaction History message (for example, Ln#: 1 Accepted by Broker) Note: Once the order line is in Accepted status, Order Management System does not write a history record for the status inquiry response as long as the record remains in this status. |

Order rejected? If the assigned fulfilling or sourcing location cannot fulfill the order or line, or the pickup location for a ship-for-pickup order indicates that the inventory for the item was not received or was damaged in transit, it sends a status update rejecting the order or line to Order Broker. Order Broker then: |

|

|

|

• Attempts to find another location, subject to the rules you have set up in Order Broker. If it finds another location, Order Broker updates the record in its database and changes the order status back to new_order. Then the process begins again as Order Broker waits until the newly-assigned location polls for orders. |

new_order |

Acknowledged (K) (after receiving status inquiry response) |

• creates an Order Broker History record (D - Receive Status Response) • writes an Order Transaction History message (for example, Ln#: 1 Acknowledged by Broker) |

• If Order Broker does not find another fulfilling location, it flags the order or line as unfulfillable by assigning it to the Default Unfulfillable Location you have set up in Order Broker (matching the OROB Default Location Code for Unfulfillable Orders (K56) in Order Management System). When Order Management System receives the status inquiry update indicating a fulfilling location that matches the OROB Default Location Code for Unfulfillable Orders (K56), it flags the order or line as unfulfillable and returns the line to standard backorder or soldout processing, clearing the Drop ship flag and the Printed quantity for the order line. |

new_order |

unfulfillable (U) (after receiving status inquiry response) |

• creates an Order Broker History record (D - Receive Status Response) • writes an Order Transaction History message (for example, Ln#: 5 Unfulfillable by Broker) |

In Transit (ship-for-pickup, retail pickup): The location assigned to fulfill a ship-for-pickup order has sent the inventory to the location where the customer will pick up the order. Once the fulfilling location has shipped the order or line, it sends a status update message to Order Broker, providing the ship via and tracking number if available. Order Broker changes the status to In Transit and stores the ship via and tracking number so that it can send this information to Order Management System. The tracking number is not available as a live link on screens. |

In Transit |

intransit |

• creates an Order Broker History record (D - Receive Status Response) • writes Order Transaction History messages indicating the ship via and the tracking number passed from Order Broker (for example, ----VIA: UPS and ----TRK#: ABCDEFG1234567890). If there is not tracking information available, writes an Order Transaction History message such as Ln#: 1 Store Shipped Order Create invoice? If the Invoice Ship For Pickup Order Once Intransit (M73) system control value is selected, Order Management System may create the invoice for the originating order when it receives a status inquiry response from Order Broker indicating that order lines on a ship-for-pickup order are now in transit. See that system control value for more information. |

Intransit Polled (ship-for-pickup): The pickup location for a ship-for-pickup order: • has received the order in the intransit response message, if the system is not flagged to Require Status Update; or • has sent a status update request changing the status to intransit polled |

In Transit Polled |

intransit polled |

• creates an Order Broker History record (D - Receive Status Response) • writes an Order Transaction History message (for example, Ln#: 1 Intransit Polled by Broker) Create invoice? If the Invoice Ship For Pickup Order Once Intransit (M73) system control value is selected, Order Management System may create the invoice for the originating order when it receives a status inquiry response from Order Broker indicating that order lines on a ship-for-pickup order are now in transit polled, if the invoice was not already created. See that system control value for more information. |

Received (ship-for-pickup, retail pickup): The transferred inventory has been received at the location where the customer is picking up a ship-for-pickup order. |

Received |

received |

• creates an Order Broker History record (D - Receive Status Response) • writes an Order Transaction History message (for example, Ln#: 1 Store Received) Create invoice? If the Invoice Ship For Pickup Order Once Intransit (M73) system control value is selected, Order Management System may create the invoice for the originating order when it receives a status inquiry response from Order Broker indicating that order lines on a ship-for-pickup order are now received, if the invoice was not already created. See that system control value for more information. |

Order shipped (delivery) or picked up (ship-for-pickup, retail pickup): Once the fulfilling location has shipped the order or line (delivery) or the customer has picked up the merchandise at the store location (ship-for--pickup), it sends a status update message to Order Broker. For delivery orders, the update message also provides the ship via and tracking number if available. Order Broker changes the status to fulfilled and stores the ship via and tracking number so that it can send this information to Order Management System. When Order Management System receives notification, it clears the Drop ship flag and the Printed quantity, and submits the order line to billing. If Order Broker provides a valid ship via code and a tracking number, the tracking number is a live link in the shipment confirmation email, although not on screens. See the OrderShipmentLineDetail in the outbound email message for details. |

fulfilled |

completed (X) (after receiving status inquiry or inquiry list response) |

• writes an Order Transaction History message (for example, Ln#: 2 Store Shipped Order) • writes Order Transaction History messages indicating the ship via and the tracking number passed, if any, from Order Broker (for example, ----VIA: UPS and ----TRK#: ABCDEFG1234567890) Billing the order: When processing status update responses for the same order, if the status of an order line changes to fulfilled, the BROKER job: • Changes the status to fulfilled for each order line if that status is indicated in the response message; • Identifies the order lines that were previously in the same status, such as accepted, and are now in fulfilled status; • Submits these order lines to billing as a single billing header record. Example: • An order previously had two lines in accepted status and one line in acknowledged status. • The response message indicates that all three lines are now in fulfilled status. • The two order lines whose status changed from accepted to fulfilled are submitted to billing under a single billing header record, creating a single invoice. • The one order line whose status changed from acknowledged to fulfilled are submitted to billing as a separate billing header record, creating a separate invoice. |

|

|

|

Note: Generating a single invoice takes place regardless of whether the fulfilled order lines have different Order Broker request IDs, provided the updates take place as described above. Note: The billing async job does not complete billing the order until one of the following occurs: • The BROKER job ends, or • Another brokered order is submitted to the billing data queue, or • All the current status inquiry responses are processed for the company. If a large number of orders were submitted in the status list request, there could be a delay of several minutes before the order is billed. Note: If there are multiple order lines confirmed as fulfilled on a single order, but for different ship-tos, this generates separate billing header records and invoice ship-tos. Multiple invoices are created for a single order if not all order lines are included in the same status list response message. |

Order status changes? If the Send Held Orders to OROB (M18) system control value is selected, Order Management System sends held brokered backorders to Order Broker, but with the Under Review flag set to Y; also, Order Management System sends an order update to Order Broker if the order’s status changes from held to open, or vice versa. |

no change |

no change |

• when the change occurs after initial order creation and submission, writes an Order Transaction History message (for example, Request ID: 78390 Under Review: N) |

Picked? If the assigned fulfilling location reports that a brokered backorder is in Picked status, the Working with Order Broker (WOBR) option indicates a status of Accepted.

Canceling a brokered backorder: See Canceling a Brokered Backorder Request for a discussion of the updates that take place when you cancel an Order Broker request at the Work with Order Broker Screen or in order maintenance.

Reviewing brokered backorders in order inquiry: You can use the Brokered Backorder Summary Screen to review the current status of all brokered backordered lines on a single order. Also, you can select D/S Status for a single brokered backorder line at the Order Inquiry Detail Screen to advance to the Display Order Broker Details Screen, where you can review a single brokered backorder line on the order.

Quantity not indicated in order transaction history messages: The order transaction history messages do not specify the quantity affected by the update; however, if you split orders and lines, the quantity affected may be less than the total order line quantity. For example, if Order Broker splits an order line across two locations for fulfillment, and one of the locations fulfills its assigned quantity, the order transaction history message of Ln#: 2 Store Shipped Order does not indicate the fulfilled quantity.

Rules for Submitting Backorders to Order Broker

To be eligible for submission to Order Broker, the backordered item must have the OROB eligible flag selected. Also, the order line must be:

• fully backordered

• in open status

In addition, if the Use OROB for Fulfillment Assignment (M31) system control value is selected or the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS and the original order is a ship-for-pickup order, the order or order line can include the following; otherwise, the order or order line cannot include the following.

• be gift wrapped

• have any special handling (Note: only custom special handling instructions are sent to Order Broker in the submit order request; however, the system does not prevent items with standard special handling from being sent to Order Broker)

• have a future arrival date or be flagged as a future order

• be for a customer flagged to bypass reservation

If the Use OROB for Fulfillment Assignment (M31) system control value is set to ALWAYS, the originating location passed to Order Broker on a delivery order is the location defined in the Originating Location to Pass to OROB (M32) system control value.

Also, if the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS, the order line can be on a ship-for-pickup order; otherwise, if this system control value is set to NEVER or blank, order lines on a ship-for-pickup order are not eligible for submission to Order Broker to determine fulfillment assignment and instead are sent to Order Broker during pick slip generation and drop ship order processing time; see Ship-for-Pickup Orders.

Regardless of the settings of the Use OROB for Fulfillment Assignment (M31) and Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control values, the order line must not be:

• Flagged as a drop ship item

• A retail pickup or delivery order received from Order Broker

• A main set item or a set component

• A membership item

• A stored value card item

• A non-inventory item

Order Management System does not consider the item’s Projected returns quantity, if any, when determining whether the item is eligible for fulfillment through Order Broker.

Also, the order must be:

• Open, if the Send Held Orders to OROB (M18) system control value is unselected; otherwise, the order can be held. In this case, the order’s Under Review flag is selected. See the system control value for more information.

• Fully paid and authorized. If the Payment at POS for Ship for Pickup Orders (L60) system control value is selected, ship-for-pickup orders are authorized for verification only and payment is collected when the customer picks up the items at the store.

System control values: If the Use OROB for Fulfillment Assignment (M31) system control value is selected or if the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS and the original order is a ship-for-pickup order, regardless of the setting of the following system control values, the system sends items to Order Broker for fulfillment assignment. Otherwise, the following system control values also determine whether an order line is eligible to send to Order Broker for fulfillment:

• Order Broker Due Date Threshold (K11): the system does not send an item to Order Broker if the item is expected on an open purchase order line for the related warehouse with a due date within the threshold defined in this system control value.

• Order Broker Include Ship Complete Orders (K12): if this system control value is unselected, the system does not send items to Order Broker that are on an order flagged to ship complete.

• Order Broker Include Coordinate Grouped Orders (K13): if this system control value is unselected, the system does not send items to Order Broker that are coordinate grouped with other items.

• Order Broker Include Gift Orders (K14): if this system control value is unselected, the system does not send items to Order Broker that are on a gift order.

Sellout prevented: If an order line meets all of the criteria, it is brokered even if the item is flagged with a soldout control code. See Brokering Items with Soldout Control Codes for a discussion.

The BROKER periodic function submits orders to Order Broker if they were not eligible for submission when they were created. For example, the periodic function submits order lines if:

• Your company was not configured to send brokered backorders to Order Broker when the order was created.

• The order was in held status at initial creation and was subsequently released from hold, and the Send Held Orders to OROB (M18) system control value is unselected.

• The order previously included an active PO item (see About Active PO Items for background).

• The order line was partially reserved, but then the reserved quantity was shipped and there is still a backordered quantity remaining on the order line. The order line is not eligible to be submitted to Order Broker until any reserved quantity is printed and shipped. Note: This situation occurs only if the Use OROB for Fulfillment Assignment (M31) system control value is unselected; also, this situation does not apply to ship-for-pickup orders sent to Order Broker for fulfillment assignment.

Note: When the periodic function submits an order line as a brokered backorder, the function performs all the updates described under Brokered Backorder Fulfillment: Initial Order Creation, but also decreases the Backorder quantity for the Item Warehouse record, since this quantity had been increased when the line was created.

If an authorization is required, the BROKER function obtains an authorization for the entire order.

See Additional Order Broker Setup in Order Management System for background on setting up the BROKER periodic function.

Brokering Items with Soldout Control Codes

Items that are OROB eligible and flagged with a S/O control code are still eligible for brokering rather than selling out, provided they meet the Rules for Submitting Backorders to Order Broker.

In addition, the following applies if the Use OROB for Fulfillment Assignment (M31) system control value is unselected and the order is not a ship-for-pickup order.

If the soldout control status is:

• sell out immediately: the item is eligible for brokering even if there is an available quantity in an allocatable warehouse.

• include on-order: the item is eligible for brokering if it is backordered. There cannot be an open purchase order that could fulfill the order that is due within the Order Broker Due Date Threshold (K11), if specified. If no Order Broker Due Date Threshold (K11) is specified, the item is eligible for brokering regardless of open purchase orders. The Projected returns quantity, if any, for the item is not evaluated; see Projected Returns for background on how you can use the Projected returns quantity to prevent selling out items in certain situations.

• exclude on-order: the item is eligible for brokering if it is backordered, regardless of whether there are any open purchase orders.

If the item is unfulfillable: If Order Broker is unable to fulfill an order line, the line returns to standard backorder or soldout processing. The process flow is:

• An item is assigned a soldout control value and would be sold out on the order if the item were not OROB eligible. Order Management System submits the order line to Order Broker, but there is no store location that can fulfill the item, so Order Broker returns a status of Unfulfillable.

• When Order Management System receives the status update from Order Broker, it changes the order line status to sold out (S) if the order line is currently eligible to sell out based on the soldout control value and availability.

• The next time you use the Processing Auto Soldout Cancellations (MASO) option, the soldout line is listed on the Auto Soldout Register, even though it did not sell out through Process Auto Soldouts and even if it is not assigned a soldout control status of 1 (sell out immediately).

• The next time you use the Generating Soldout Notifications (MSON) option, Order Management System generates a soldout notification.

The same processing occurs if Order Broker returns an error for the brokered order line.

Gift wrap or special handling: Based on the Rules for Submitting Backorders to Order Broker, if the Use OROB for Fulfillment Assignment (M31) system control value is unselected or the order is not a ship-for-pickup order, an order line is not eligible for brokering if it is flagged for gift wrap or special handling. If gift wrap or special handling applies to the item:

• When the order line is initially created, then the line does not broker; instead, it sells out or remains backordered, as if it were not flagged as OROB eligible. This is the case when the order API or ecommerce interface creates the order.

• After the order line is initially created (for example, by selecting Special Handling for the line in order entry), then if the soldout control status is:

• sell out immediately: the line sells out the next time you use Processing Auto Soldout Cancellations (MASO).

• include on-order quantity or exclude on-order quantity: the line does not sell out automatically.

You can use a backorder report to identify order lines that could not be brokered because of gift wrap or special handling, and that did not sell out automatically. See Order Status and Activity Reports for more information.

Future orders: If the Use OROB for Fulfillment Assignment (M31) system control value is unselected or the order is not a ship-for-pickup order, future orders are not eligible to be brokered; in this situation, items flagged OROB eligible and assigned soldout control values sell out automatically on future orders, just as they would if they were not flagged OROB eligible. Once an order is no longer considered a future order, OROB eligible items on the order can be brokered through the BROKER periodic function if they meet the Rules for Submitting Backorders to Order Broker.

If reserving against a non-allocatable warehouse: Based on the Reserve from Non-Allocatable Warehouse (J25) and Disregard Soldout Controls for Non-Allocatable Warehouses (J27) system control values, you can reserve inventory against a non-allocatable (retail) warehouse for a retail order, and disregard an item’s soldout control assignment. In this case, even if the item’s OROB eligible field is selected, the item reserves against the non-allocatable (retail) warehouse if the order type is associated with that warehouse and there is inventory in that warehouse.

Things to Note About Brokered Backorders

Canceling order lines: It is important to confirm that the remote store location assigned to fulfill the order line has not begun the shipment process before you cancel an order line or Order Broker request in Order Management System. Depending on the Order Broker Status Update Interval (K10), the most current information about the Order Broker request in Order Management System might be out of date.

Freight charges included? Freight charges for the order are included in the SubmitOrder message only if the Use Split Order (L56) system control value is selected.

Customer address updates: If you change the customer’s name or address in Order Management System after generating the initial Order Broker request, the Order Broker integration does not send this updated information to the assigned fulfilling location. For ship-for-pickup orders, the system does not allow you to change the store location defined as the one-time ship-to address on the order once the order is accepted.

Held orders submitted? When the Send Held Orders to OROB (M18) system control value is unselected, if an order is initially created in held status and then released from hold, Order Management System does not automatically submit the order to Order Broker. To submit the order, you can run the BROKER Periodic Function (program PFR0083). See Order Broker Configuration for background.

Order lines not resubmitted: If an order line has previously been submitted to Order Broker and the Order Broker request was flagged as unfulfillable or put in error status, the BROKER periodic function does not resubmit the order line to Order Broker for fulfillment.

Reserve quantity limit: If an order line exceeds the Reserve qty (Reserve quantity limit) specified for an item, Order Management System still submits the order line to Order Broker for fulfillment, provided the line is eligible based on the Rules for Submitting Backorders to Order Broker.

Inventory transaction history: If the Create Item Transaction History for Non-Inventory Items (E39) system control value is selected, Order Management System writes a NONINVISSU transaction record when the BROKER process receives a status update indicating that the assigned location has shipped the order or line. See that system control value for more information.

Backorder notices: The Generate Backorder Notices (GBOC) option does not generate backorder notices for an order line when it has an Order Broker request in process; however, if the status of the Order Broker request changes to unfulfillable (U) or error (E), or if you cancel the Order Broker request (Z) without canceling the order line itself, the order line returns to standard backorder processing and is eligible to have backorder notices generated.

Tracking numbers in shipment confirmation email: If the fulfilling location supplies information on the shipping agent and a tracking number, Order Broker passes this information to Order Management System. If the shipping agent matches a valid ship via code in Order Management System, the shipment confirmation email lists the description of the ship via and the tracking number as a live link. Otherwise, if the shipping agent does not match a ship via set up in Order Management System, then the shipment confirmation lists the shipping agent as it was passed from Order Broker, and the tracking number is plain text.

Note: If a brokered backorder ships on the same day as a warehouse shipment, the shipment confirmation email includes just the tracking number for the brokered backorder. This occurs regardless of whether you consolidate invoices.

See the Shipment Confirmation Email Sample and Contents for more information, and see the OrderShipmentLineDetail for detailed mapping.

Important: In Order Management System 21.0 or higher, you cannot select the Consolidated Invoice system control value if it is not already selected. If the system control value is currently selected (set to Y) and you deselect it (change it to N or blank), you cannot then change it back to selected. The option to consolidate invoices will be removed at a later date.

Tracking numbers in customer history API: If Order Broker passes the shipping agent and a tracking number, the Detailed Order Inquiry Response XML Message (CWORDEROUT) includes this information provided Order Management System can link the line number, shipping agent, and tracking number from the Order Transaction History messages to the invoice based on date.

Example: |

The fulfilling location supplies information on the shipping agent and the tracking number to Order Broker, and Order Broker passes this information to Order Management System. Order Management System writes Order Transaction History records such as: SHIPMENT Ln#: 5 Store Shipped Order SHIPMENT ----VIA: ABC SHIPMENT ----TRK#: ABI123 The Order Transaction History records have the same date as the invoice. The CWORDEROUT message passed through the customer history API includes the tracking information, for example: <Shipment invoice_nbr="123456" invoice_ship_quantity="1" invoice_ship_date="11292011" invoice_tracking_nbr="ABI123" invoice_ship_via_desc="ABC"/> |

Note:

• If Order Management System writes the Order Transaction History for the shipment of a brokered backorder on a date that differs from the invoice date, then no tracking information is included in the customer history response. This situation might occur if, for example, Order Management System receives the status update of the shipment before midnight, but the billing async job does not create the invoice until after the job is automatically stopped and restarted, so that the next date is assigned to the invoice.

• The tracking information from Order Brokeris not available as a live link on screens.

Other Order Broker orders not eligible: Order Management System does not submit a backordered delivery or retail pickup order to Order Broker for fulfillment. In addition, if the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER or blank, Order Management System does not submit a backordered ship-for-pickup order to Order Broker for fulfillment.

Line_locate_eligible flag in the CWORDEROUT message: If the Send B/O to OROB (K08) system control value is selected, the Detailed Order XML Response (CWORDEROUT) message used in the generic order API includes a flag for each order line to indicate whether the order line meets the Rules for Submitting Backorders to Order Broker. Even if this flag is set to Y, it is possible that the line cannot be fulfilled as a brokered backorder if, for example, Order Broker does not find a location that has the item available.

The Generic Customer History API also uses the CWORDEROUT message. The message includes the line_locate_eligible flag if the order line is still open. In the case of the generic customer history API, the line_locate_eligible flag might be set to Y even if, for example, the line was already submitted to Order Broker, and then returned to normal backorder processing because Order Broker did not find a location to fulfill it.

Order Broker requires postal code: If the shipping address on a brokered backorder does not include a postal code, the Order Broker Order Broker rejects it. The Require postal code? flag for the country determines whether a postal code is required. See Setting Up the Country Table (WCTY) for background.

Reviewing brokered backorders in order inquiry: You can use the Brokered Backorder Summary Screen to review the current status of all brokered backordered lines on a single order. Also, you can select D/S Status for a single brokered backorder line at the Order Inquiry Detail Screen to advance to the Display Order Broker Details Screen, where you can review a single brokered backorder line on the order.

The OBR status remains on each order line that is fully or partially fulfilled through Order Broker as a brokered backorder. This status is displayed on the Order Inquiry Detail Screen.

The original backorder reason remains on the order line after fulfillment through Order Broker as a brokered backorder. This reason is displayed on the Display Order Detail Screen (Reviewing Order Line Detail). Typically, the backorder warehouse also remains on the order line as well, and is displayed on the Display Order Detail Screen (Reviewing Order Line Detail); however, if a shipment from the warehouse follows the fulfillment through Order Broker, the backorder warehouse field is cleared.

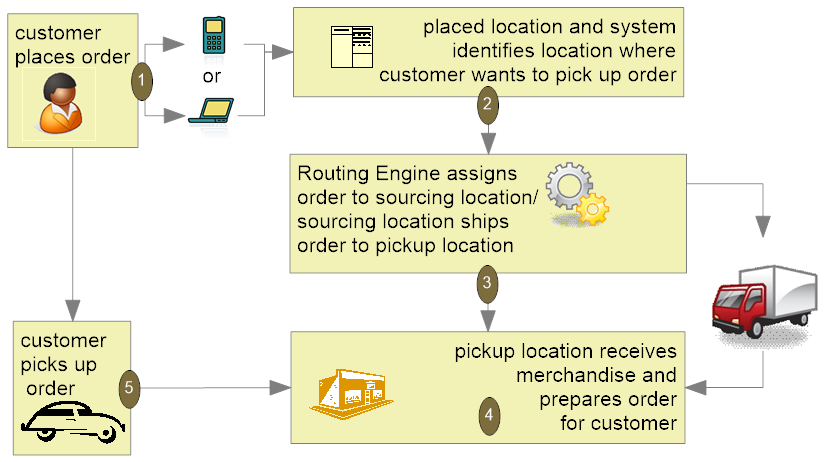

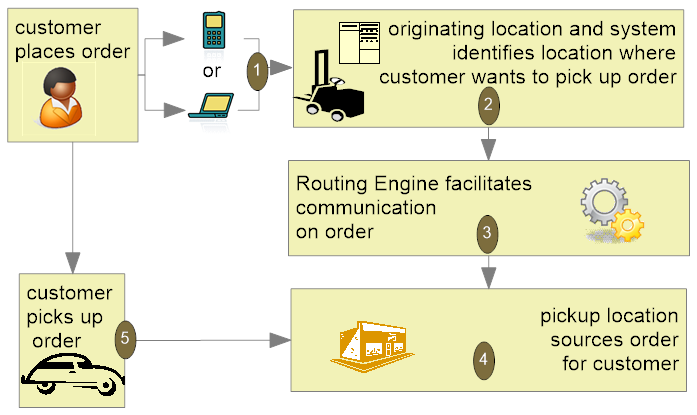

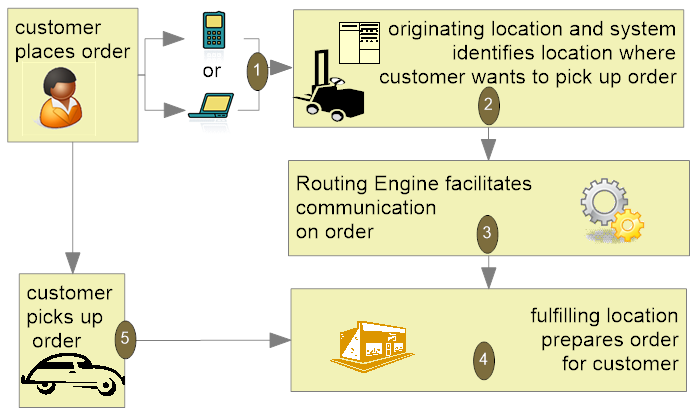

Overview: You can use the ship-for-pickup option in the Order Broker Integration to send the merchandise for an order to a designated store, where the customer can pick it up. The Order Broker integration facilitates communication between Order Management System and the designated store location, so the store receives notification that the order is in transit, and sends notification back to Order Management System after the merchandise is received and when the customer picks up the order.

The items on the order do not need to be stocked in the store. In addition, the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value controls whether Order Management System fulfills the order or whether the order is sent to Order Broker for fulfillment assignment.

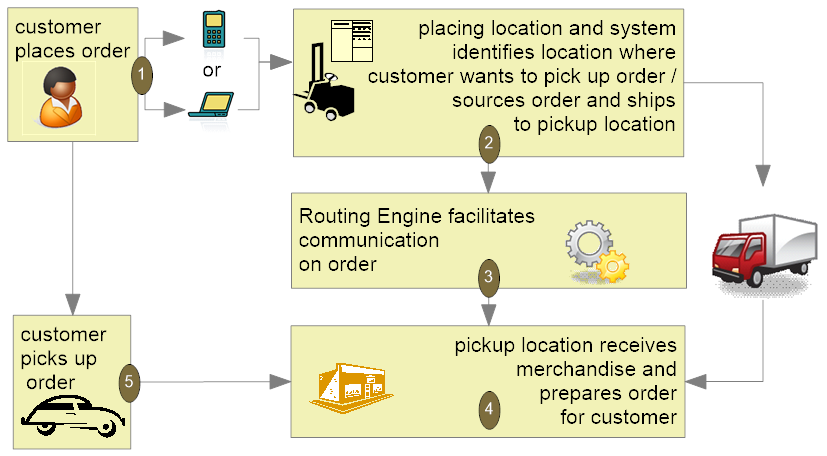

• If this system control value is set to NEVER, Order Management System fulfills the order and sends the items on the order to the store selected for customer pick up. In this situation, if an item on the order is not in stock, the item is placed on backorder until it can be fulfilled by Order Management System. The order can include up to two locations for processing:

• The originating, or placed, location that creates the order. For ship-for-pickup orders, the originating location is always an Order Management System warehouse.

• The fulfilling, or sourcing, location that provides the inventory for the order. If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER, this is always an Order Management System warehouse.

• The pickup location where the customer picks up the items on the order. For ship-for-pickup orders, this is always the store location the customer selected for pickup.

• If this system control value is set to ALWAYS, the system sends the order to Order Broker for fulfillment assignment. In this situation, Order Broker determines the best location to fulfill the order and the order can include up to three locations for processing:

• The originating, or placed, location that creates the order. For ship-for-pickup orders, the originating location is always an Order Management System warehouse.

• The fulfilling, or sourcing, location that provides the inventory for the order. If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS, this is the location Order Broker selected for fulfillment of the order. This location can be a store location or an Order Management System warehouse.

• The pickup location where the customer picks up the items on the order. For ship-for-pickup orders, this is always the store location the customer selected for pickup.

If Order Broker determines that Order Management System is the best location to fulfill the order, the system creates a new retail pickup order in Order Management System to fulfill the ship-for-pickup order; see Retail Pickup (including Ship-for-Pickup) or Delivery Orders.

Important: Regardless of when you send ship-for-pickup orders to Order Broker, in order to use ship-for-pickup processing, you must select the Enable Ship For Pickup option on the Organization window in Order Broker. Once you enable ship for pickup, the Ship for Pickup Enabled Date displays on the Organization window and this option cannot be changed.

Examples: Examples of ship-for-pickup include:

Example 1 (three different locations): |

The customer places an order on the web site (originating location A, Order Management System) and wants to pick the order up at store location B. Order Broker selects store location C as the fulfilling, or sourcing, location. Store location C ships the inventory to store location B, where the customer can pick it up. |

Example 2 (fulfilling location and pickup location are the same): |

The customer places an order on the web site (originating location A, Order Management System) and wants to pick the order up at store location B. Order Broker selects store location B as the fulfilling, or sourcing, location. Once the order is ready at store location B, the customer can pick it up. |

Example 3 (originating location and fulfilling location are the same): |

The customer places an order on the web site (originating location A, Order Management System) and wants to pick the order up at store location B. Order Broker selects warehouse location A, Order Management System, as the fulfilling, or sourcing, location. Order Management System ships the items on the order to store location B. Once the order is ready at store location B, the customer can pick it up. |

Example 4 (originating location and fulfillment location are the same; items on the order are shipped to the store during pick slip generation/drop ship processing): |

The customer places an order on the web site (originating location A, Order Management System) and wants to pick the order up at store location B. Order Management System fulfills the items on the order and during pick slip generation, ships the items on the order to store location B. Order Broker manages communication between Order Management System and store location B. Once the order is ready at store location B, the customer can pick it up. |

Version compatibility: Fulfillment assignment and ship-for-pickup functionality is available in release 16.0 or higher of Order Management System and release 16.0 or higher of Order Broker. Also, in order to use ship-for-pickup processing, you must select the Enable Ship For Pickup option on the Organization window in Order Broker. Once you enable ship for pickup, the Ship for Pickup Enabled Date displays on the Organization window and you cannot deselect this option.

An OROB_MESSAGE_VERSION of 16.0 or higher is required to use the Ship-for-Pickup Orders integration with Order Broker.

In this topic:

• Creating a Ship-for-Pickup Order in Order Management System

• Communicating with Order Broker about a Ship-for-Pickup Order

• Special Ship-for-Pickup Orders

• Collect Payment for a Ship-for-Pickup Order at the Store?

• Updates to a Ship-for-Pickup Order in Order Management System

• Ship-for-Pickup Order Processing on or after Shipment

• Reviewing a Ship-for-Pickup Order in Order Inquiry

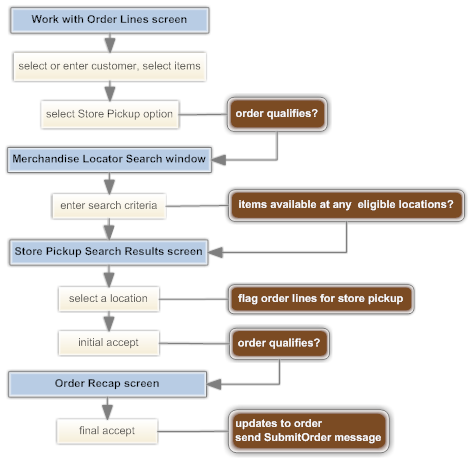

Creating a Ship-for-Pickup Order in Order Management System

You can create a ship-for-pickup order through interactive order entry, or through the order API.

Note: A ship-for-pickup order should have a single ship-to.

Creating a Ship-for-Pickup Order in Order Entry

Ship-for-pickup orders originate in Order Management System, either through order entry or through the generic order API. The order creation process is similar to that of a regular order, except that a ship-for-pickup order includes a one-time ship-to address representing the store location.

To select the store location in order entry:

1. Select the One Time Ship To option.

2. At the Create One Time Ship To Address Screen, select Store.

3. Select a store at the Store Location Screen. This screen displays each store location set up through Work with Store Cross Reference (WSCR) whose Ship for Pickup flag is selected. The description and address set up for the Store Cross Reference default to the Create One Time Ship To Address screen.

4. Complete entry of the order.

• If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER, the system uses existing logic to reserve items in order to fulfill the ship-for-pickup order from an Order Management System warehouse. See Sending a Ship-for-Pickup Order to Order Broker during Pick Slip Generation and Drop Ship Order Processing.

• If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS and the Send B/O to OROB (K08) system control value is selected, the system bypasses reservation and places all eligible items on backorder, even if the item is available in an Order Management System warehouse, in order to send all eligible items to Order Broker for fulfillment assignment; see Rules for Submitting Backorders to Order Broker. Order Broker will choose the best store location or Order Management System location to fulfill and ship the item to the store location selected by the customer for store pickup. See Brokered Backorders for processing details.

Note: To avoid shipment problems, once you accept a ship-for-pickup order, the system does not allow you to change the store selected as the one-time ship-to address; in order to change the pickup store location, you must cancel the order and create a new ship-for-pickup order.

Ship-alone items on ship-for-pickup orders: If an item is flagged as Ship alone, Order Management System does not let you enter an order line on a ship-for-pickup order with a quantity greater than one. If the customer wants more than one unit, enter a separate order line for each unit. This restriction applies even if the item is not flagged as OROB eligible.

Creating a Ship-for-Pickup Order through the Generic Order API

In the Inbound Order XML Message (CWORDERIN):

• use the store_code attribute to specify the store location code. This needs to be a store location set up through Work with Store Cross Reference (WSCR), as described above for order entry.

• specify a delivery_type of S

• use the ShipTo element in the Inbound Order XML Message (CWORDERIN) to specify the shipping address of the store, or leave the shipping name and address attributes blank in order to use the information set up in the Store Cross Reference record.

Name and address for ship-for-pickup order: If the ship-to name and address fields are passed for a ship-for-pickup order, these fields should indicate the shipping address of the store selected for pickup; otherwise, if no ship-to name and address is passed, the information defaults from the Store Cross Reference record.

Partial ship-to address? The name or address fields from the Store Cross Reference record default for any fields not passed in the message.

Example: If the CWOrderIn message indicates the ship-to customer’s first and last name, this information defaults to the order, in addition to the company name and address from the Store Cross Reference record.

Communicating with Order Broker about a Ship-for-Pickup Order

Submitting the order to Order Broker: The setting of the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value controls when the order is submitted to Order Broker.

The system submits a ship-for-pickup order to Order Broker for fulfillment assignment when the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS and the Send B/O to OROB (K08) system control value is selected, and:

• You create an order that contains an eligible item in interactive order entry or through the generic order interface (Order API).

• You run the BROKER Periodic Function to find eligible items to send to Order Broker.

See Brokered Backorders for processing details.

The system submits a ship-for-pickup order to Order Broker during pick slip generation or drop ship purchase order processing in the following scenarios.

• When the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER or blank, or

• When the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS but the Send B/O to OROB (K08) system control value is unselected.

See Sending a Ship-for-Pickup Order to Order Broker during Pick Slip Generation and Drop Ship Order Processing for processing details.

Sending a Ship-for-Pickup Order to Order Broker during Pick Slip Generation and Drop Ship Order Processing

Submitting the order to Order Broker: The system submits a ship-for-pickup order to Order Broker when you generate the pick slip or drop ship purchase order in the following scenarios.

• When the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER or blank.

• When the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS but the Send B/O to OROB (K08) system control value is unselected.

At this time, the system also creates the Order Broker record displayed at the Work with Order Broker Screen.

Which items are included in the Submit Order message? Only items that are flagged as OROB eligible are included in the message to Order Broker. However, all items that print on the pick slip or purchase order can be included in the shipment to the store location.

Note: It is important to confirm that including additional items on the pick slip or purchase order and in the shipment will not present a problem to the store receiving the ship-for-pickup order.

No items OROB eligible? If you create a ship-for-pickup that does not include any OROB eligible items, Order Management System does not submit the order to Order Broker or create an Order Broker record; however, you can still generate the pick slip or drop ship purchase order and ship the order to the store location for customer pickup. It is important to note that, in this case, the selected store does not receive advance notification of the order.

For more information on the contents of the message, see the Ship-for-Pickup (during Pick Generation/Drop Ship Processing) Submit Order Request Message Sample.

Submit separate orders for each order line? If the Create Separate Picks for Ship for Pickup Orders (L89) system control value is selected, Order Management System generates a separate pick slip or drop ship purchase order for each item, and as a result, submits each order line as a separate order to Order Broker. Creating separate orders in Order Broker can prevent confusion about order status if, for example, a single order line is canceled or fulfilled. See the Create Separate Picks for Ship for Pickup Orders (L89) system control value for more information.

What if Order Broker is unavailable? If Order Broker does not respond to the submit order request during pick slip or drop ship purchase order generation, Order Management System does not print the pick slip or purchase order. Instead, it writes an order transaction history message: Submit Order Failed - OROB Unavailable. The order is eligible for selection the next time you generate pick slips or drop ship purchase orders.

Creating the Order Broker record: When the job generates the Submit Order request, it initially creates the Order Broker record in In Process status.

Message response: The Submit Order response message indicates whether Order Broker was able to create the order:

• Order rejected? If Order Broker returns an error in the response message, Order Management System puts the order on hold using the Hold Reason for Errored Ship for Pickup Orders (L10). Order Broker might return an error if, for example, the order includes an item that does not exist in Order Broker or in the point-of-sale system associated with the store location. In this case, the Order Broker record in Order Management System is deleted and Order Transaction History indicates:

Submit Order Rejected/Order Held

Rsn:PRODUCT NOT STOCKED IN REQUESTED LOC

ATION.

• Order accepted? If Order Broker accepts the order, the generation process sends a status update indicating a status of Picked. The process finishes and the Order Broker record remains in Picking status until you confirm shipment of the pick slip or purchase order.

Note: The designated store location cannot reject a ship-for-pickup order.

Sample message: See Ship-for-Pickup (during Pick Generation/Drop Ship Processing) Submit Order Request Message Sample for a sample message and more information.

Fulfilling location in Order Management System vs. Order Broker:

• When order submitted to Order Broker:

• originating / placed location = the OROMS warehouse shipping the merchandise to the store location.

• fulfilling / sourced location = the OROMS warehouse shipping the merchandise to the store location.

• pickup location = the store location the customer selected for store pickup.

• When store receives the merchandise or customer picks up the order: Once Order Management System receives a status inquiry response indicating that the store location has received the merchandise on the order, or that the customer has picked the order up, the store location is identified as the fulfilling location.

• originating / placed location = the OROMS warehouse shipping the merchandise to the store location.

• fulfilling / sourced location = the OROMS warehouse shipping the merchandise to the store location.

• pickup location = the store location the customer selected for store pickup.

Excluded from brokered backorder processing: If the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to NEVER, backordered items on ship-for-pickup orders are not eligible for processing through the brokered backorder integration with Order Broker.

Creating ship-for-pickup orders for drop ship items: When you create a ship-for-pickup order for a drop ship item, Order Management System submits the order to Order Broker when you use Selecting Vendors for Drop Ship Processing (MDSP).

Note: There is no warehouse associated with a drop ship item, so in this case Order Management System designates the OROB Default Location (K51) as the requesting location. If you are generating ship-for-pickup orders for drop ship items, you need to specify a valid Order Broker location in this system control value; otherwise, Order Broker returns an error indicating that the requesting location is invalid.

Documents for store receiving: In order to support store receiving, you can generate the Pick Message from Order Management System (CWPickOut) or the PO Download XML Message (CWPurchaseOrderOut). Each of these messages includes details on the order submitted to Order Broker, including the Order Broker request ID, the order number in the originating system, and the delivery type. See the Generic Pick Out API and the Generic Outbound Purchase Order API for more information.

Special Ship-for-Pickup Orders

In order to support processing special ship-for-pickup orders that originated in a retail location and then sent to Order Management System through the order API:

• If the order type matches the Order Type for Special Orders (L15), the Submit Order message specifies the e-commerce order number, rather than the Order Management System order number, as the order_id, so that the originating location can more easily identify and track the order.

• If the pay type matches the Pay Type for Special Orders (L16), the balance_due specified in the Submit Order message is the order total, indicating that the customer needs to pay for the order when picking it up. Otherwise, if the pay type on the order does not match this system control value, the Submit Order message does not specify a balance due, even if the order type matches the Order Type for Special Orders (L15).

See the Order Type for Special Orders (L15) and Pay Type for Special Orders (L16) system control values for more information.

If you use the Generic Pick In API (Shipments, Voids, and Backorders) to void a pick slip for a special ship-for-pickup order and the Cancel Reason (Pick In) (L86) system control value specifies a cancel reason code, or a backorder cancel reason is specified in the CWPickIn XML Message, Order Management System cancels the order using the specified cancel reason and sends a status update to Order Broker canceling the order.

Important: To prevent inconsistent updates to Order Broker for special ship-for-pickup orders, do not process partial backorders for these orders through the Generic Pick In API (Shipments, Voids, and Backorders); confirm or void the entire pick slip.

Collect Payment for a Ship-for-Pickup Order at the Store?

You can use the Payment at POS for Ship for Pickup Orders (L60) system control value to indicate that the customer pays for a ship-for-pickup order when picking up the order at the store, rather than billing the order when you ship it to the store from the warehouse. In this case:

• The order must include only credit card payment methods; also, each pay type’s Card type must be set to Credit. No other card types, such as stored value cards, can be included.

• The payment method’s Suppress deposit and Suppress refund flags are set to Y.

• The payment method is authorized for $1.00 only during online authorization.

• Authorization is suppressed during pick slip generation.

• Order Management System sends the order total to Order Broker as the balance_due in the Submit Order message.

Note: The above restrictions do not apply to ship-for-pickup orders whose order type matches the Order Type for Special Orders (L15).

Returns suppressed: Selecting the Payment at POS for Ship for Pickup Orders (L60) system control value suppresses most options for creating a return authorization, processing a return, and creating a refund. See that system control value for details.

Updates to a Ship-for-Pickup Order in Order Management System

Add an item? If you add an item to a ship-for-pickup order, or are able to ship a backordered item once you have generated the pick slip and created the ship-for-pickup order in Order Broker, the new item is not added to the original Order Broker record or to the order in Order Broker. Printing the pick slip for the new order line creates a new Order Broker record and a new order in Order Broker.

Voiding or reprinting a pick slip: Order Management System sends a status update to Order Broker if you void a pick slip for an order line on an existing ship-for-pickup order:

• Special ship-for-pickup orders: If the Cancel Reason (Pick In) (L86) system control value specifies a cancel reason or if a backorder cancellation reason code is specified in the CWPickIn XML Message, and you void the pick slip for a special ship-for-pickup order through the generic pick in API, Order Management System cancels the order or line and sends a cancellation to Order Broker, including the cancel reason from the system control value. See Special Ship-for-Pickup Orders for background on these orders.

• Regular ship-for-pickup orders: If the Create Separate Picks for Ship for Pickup Orders (L89) system control value is selected and you void the pick slip for a regular (not special) ship-for-pickup order, Order Management System does not cancel the order or line, but it does send a cancellation to Order Broker. No cancel reason is included in this case. This status update occurs regardless of whether you use the generic pick in API to void the pick slip, or void it at a Order Management System screen.

If you then reprint the pick slip for a regular ship-for-pickup order in this situation, Order Management System submits a new order to Order Broker; however, if you cancel the order after voiding the pick slip, no update is sent to Order Broker.

Aside from the two scenarios described above, Order Management System does not send a status update to Order Broker when you void or reprint a pick slip.

Canceling a ship-for-pickup order: Aside from the two scenarios, described above, which generate status updates for voided pick slips, Order Management System sends a status update to Order Broker when you cancel the order or item. In most cases, this status update includes the cancel reason you enter:

• Cancel after voiding pick slip: If you cancel an item or the entire ship-for-pickup order in order maintenance after voiding the pick slip, and Order Management System has not already sent a status update when the pick slip was voided, it sends a status update that includes the cancel reason you enter. This situation can occur if, for example, you void a ship-for-pickup order through the Void/Reprint Picks menu option, or if you void a regular ship-for-pickup order with the Create Separate Picks for Ship for Pickup Orders (L89) system control value unselected.

• Cancel drop ship purchase order in purchase order maintenance: If you cancel a drop ship purchase order in purchase order maintenance, Order Management System sends a status update that includes the Auto Soldout Cancel Reason (C20), since you do not have an opportunity to enter a cancel reason in this case.

• Cancel drop ship purchase order sent to vendor through drop ship integration: To cancel items fulfilled through the drop ship integration, you need to use the Display P/O Drop Ship Screen in order inquiry. If you cancel a drop ship purchase order at this screen, and the purchase order is successfully canceled through the drop ship integration, it sends a status update that includes the cancel reason you enter.

Note:

• Canceling single item cancels entire order in Order Broker: If you do not split orders and the pick slip creating the order in Order Broker included multiple items, canceling a single item in Order Management System results in canceling the entire order in Order Broker. This situation might occur if the Create Separate Picks for Ship for Pickup Orders (L89) system control value is not selected.

• Canceling before order created in Order Broker: If you cancel the order before pick slip generation or drop ship purchase order generation, there is no need to notify Order Broker, since the order was never sent.