6 Fulfillment

Reserving Inventory and Generating Pick Slips

Topics in this part:

- Reviewing Reservation Types describes the three types of reservations: Immediate, Batch, and Interactive.

- Reviewing Other Reservation Conditions discusses other reservation conditions, such as: Coordinate grouping, drop ship reservations, special handling reservations, and reserving inventory for sets and variable sets.

- Working with Interactive Reservation (MIRV) discusses creating, changing, deleting, and displaying order information using this reservation type.

- Preparing Orders for Pick Slip Generation provides an overview on preparing an order for pick slip generation.

- Performing Pick Slip Generation includes locating the pick slip generation function, printing pick slips, performing cubing, selecting pick locations, replenishing stock, and using cart/bin picking.

- Selecting Vendors for Drop Ship Processing (MDSP) includes creating, changing, deleting, and displaying vendors for drop ship processing.

- Displaying Pick Slip Generation Inquiry (DPSI) describes this management tool.

- Working with Pick Slip Messages (WPSM) describes creating, changing, deleting, and displaying pick slip messages.

- Processing Drop Ship Orders by Batch (MDSB) describes how to generate drop ship picks by batch for selected vendors.

- Printing the Carryover Report (PCOR) describes how to generate the Carryover reports.

- Generic Pick Out API describes how to generate the outbound pick slip message for integration with another system.

- Pick Message from Order Management System (CWPickOut) describes

the Pick Message from the Order Management System.

For more information see the Web Services Guide on https://support.oracle.com My Oracle Support (ID 2149144.1).

- Streamlined Pick Slip Generation (WSPS) describes a streamlined version of the pick slip generation option.

- Pick Print Eligibility (WPPE) determines whether the system will include picks for a specified order in the next pick slip generation run for the selected pick slip generation template.

- Unlock Pick Slip (MUPI) allows you to unlock a pick slip.

Working with Interactive Reservation (MIRV)

Purpose: Use this option to reserve stock for specific orders, customer classes, or items via an interactive entry program. You can use interactive reservation in conjunction with Immediate Reservation. Interactive reservation enables you to selectively distribute stock over many orders, or to manually select preferred customers to receive inventory.

You can also use the interactive reservation program to reserve any backordered zone-reservation-coded items not reserved through the zone reservation process. Zone-reservation-coded items are excluded from normal backorder processing.

Quotes: Inventory on quotes is not eligible for interactive reservation; see Entering Pre-Order Quotes for an overview and required setup.

In this topic:

- Scanning for Orders

- Interactive Reservation Screen

- Work with Order Detail Reservations Screen

- Scan Orders by Customer Class Screen

- Work with Reservations by Item/SKU Screen

Scanning for Orders

Use the Interactive Reservation Screen to select an order number, customer class, or item/SKU for reservation.

- Order numbers are unique numbers assigned by the system to identify an order.

- Customer class codes are used to restrict certain customers who order in large quantities from immediate reservation in order entry.

- Item/SKU codes represent units of inventory.

When you enter information in any of these fields, you advance to the next screen based on the first field that has an entry. For example, if you enter an order number and a customer class, you first advance to the Work with Order Detail Reservations Screen, and then to the Scan Orders by Customer Class Screen.

Pick slip preparation: The system removes any pick slip preparation from an order when you:

- scan by order number.

- scan by customer class and select an order.

- scan by item/SKU and perform an action against an item on the order.

When you exit Interactive Reservation, the system determines if the order qualifies for pick slip preparation, and if so, applies it to the order. See Preparing Orders for Pick Slip Generation.

Interactive Reservation Screen

How to display this screen: Enter MIRV in the Fast path field at the top of any menu or select Interactive Reservation from a menu.

| Field | Description |

|---|---|

|

Order # |

A unique number assigned by the system to identify an order. Enter a valid order number to advance to the Work with Order Detail Reservations Screen. If you enter an invalid order number, you advance to the Scan by Order Number screen. Inventory on

quotes is not eligible for interactive reservation: Numeric, 8 positions; optional. |

|

Customer class |

A code to identify a group of customers. You can direct offers to specific classes of customers or generate lists by customer class code. Enter a valid code to advance to the Scan Orders by Customer Class Screen. Customer class codes are defined in and validated against the Customer Class table; see Setting Up the Customer Class Table (WCCL). Alphanumeric, 2 positions; optional. |

|

Item/SKU |

The code that represents the item/SKU. Enter a valid code (both item and SKU) to advance to the Work with Reservations by Item/SKU Screen. Item: alphanumeric, 12 positions; optional. SKU: alphanumeric, three 4-position fields; optional. |

Work with Order Detail Reservations Screen

Purpose: Use this screen to select items for review, or to work with reservations by warehouse.

How to display this screen: Complete the Order # field on the Interactive Reservation Screen.

| Field | Description |

|---|---|

|

Shp (Ship to number) |

A system-assigned number that represents the number of shipping addresses for the order. Numeric, 3 positions; display-only. |

|

Ln# (Line number) |

A system-assigned detail line number on the order. Numeric, 3 positions; display-only. |

|

Item |

A code used to identify a unit of inventory. Alphanumeric, 12 positions; display-only. |

|

COLR SIZE OTHR |

A code used to further define the item. Alphanumeric, three 4-position fields; display-only. |

|

Qty avail |

The quantity of the item that is available to sell in this warehouse. A negative number indicates the item is backordered. The calculation for availability is:

Takes into account only reservable locations. Numeric, 7 positions; display-only. |

|

Qty prot (Quantity protected) |

The quantity of the item that can be reserved only through Interactive Reservation where inventory is dispersed manually, as in the case of large wholesale orders or preferred mail order customers. The system uses this field to reserve the component items on a finished good work order if Use Work Order Processing (E37) is selected in the System Control table. See Finished Good Work Order Processing (WWOR) for more information on work orders. Numeric, 5 positions; display-only. |

|

Qty open (Quantity open) |

The total number of units that have not shipped. Numeric, 5 positions; optional. |

|

Qty rsrvd (Quantity reserved) |

The quantity of the item that is set aside for existing orders. Increases by immediate and interactive reservation and decreases by confirmation or pick void/reprint. Numeric, 5 positions; optional. |

|

Qty to reserve |

The number of units of the item that you want to reserve for this order. Numeric, 5 positions; required. |

| Screen Option | Procedure |

|---|---|

|

Display order details |

Select Order detail for an order detail line to advance to the Display Order Detail Reserve Information Screen. |

|

Display reserve by warehouse details |

Select Reserve by Warehouse for an order detail line to advance to the Work with Reservations by Warehouse Screen. |

|

Display reserved order lines |

Select Reserved Order Lines for an order detail line to advance to the Display Reserved Order Lines Screen. |

Display Order Detail Reserve Information Screen

Purpose: Use this screen to review reservation information for an order detail line.

How to display this screen: Select Order detail for an order detail line on the Work with Order Detail Reservations Screen.

| Field | Description |

|---|---|

|

Order |

A unique number assigned by the system to identify an order. Every order on the system is assigned an order number. Numeric, 8 positions; display-only. |

|

Ship-to number (Unlabeled field to the right of the order number) |

A hyphen (-) separates this field from the Order # field. Indicates the number of shipping addresses for the order. The system assigns a sequential ship-to number to every order. The first ship-to address is assigned the number 1. Numeric, 3 positions; display-only. |

|

Line number (Unlabeled field to the right of the ship-to number) |

A hyphen (-) separates this field from the Ship-to field. The line number on the order. Up to 999 detail lines may be entered on an order. Order lines are presented in descending sequence so that the most recent order line displays first. Numeric, 3 positions; display-only. |

|

Status |

The status of the order detail line. Valid values:

Alphanumeric, 1 position; display-only. |

|

Item |

A code and description of the unit of inventory on an order detail line. If a SKUed item is displayed, the SKU information will also appear. Alphanumeric, 12 positions; display-only. |

|

Override warehouse |

The code and description of the warehouse that supersedes the default warehouse, defined in the System Control table. Numeric, 3 positions; display-only. |

|

Backorder warehouse |

The code and description of the warehouse that the order detail line was backordered from. Numeric, 3 positions; display-only. |

|

Backorder date |

The date when the order detail line was printed on the backorder notification form. This form is sent to a customer when an order detail line is delayed in shipping. Numeric, 6 positions; display-only. |

|

Backorder reason |

The reason an order detail line was backordered. Alphanumeric, 25 positions; display-only. |

|

Bypass reservation |

A code which indicates whether the item is flagged to bypass reservation in order entry.

Note: If the Use OROB for Fulfillment Assignment (M31) system control value is selected, the system uses the Bypass reservation flag to send orders to Order Broker for fulfillment assignment. |

|

Drop ship flag |

Indicates whether this item is an item that you typically do not stock in inventory; drop ship items must be ordered and shipped from your supplier (vendor). These types of items are not generally available for Reservation. The system creates a separate pre-generated pick for drop ship items to print and forward to the vendor. Additionally, drop ship items must be billed via a special drop ship billing program (because the vendor must notify you when the items have shipped so that you do not bill the customer before the merchandise is received). Valid values:

Display-only. |

|

Future order |

Valid values:

How the system evaluates future orders: 1) The system adds today's date and the Reservation Lead Days (B27) and compares this value against the Arrival date on the order. If the result is greater than the Arrival Date, the system:

2) Typically, you run the Evaluate Future Orders program each evening to evaluate each order detail line marked as a “future order.” The system adds today's date to the Reservation Lead Days value and compares the result against the order's Arrival Date. This comparison determines when inventory can be reserved for a future order. When the result is less than or equal to the Arrival Date, the “future order” flag will be removed from each detail line on the order and each line will be eligible for reservation. |

|

Expected ship date |

The date on which a purchase order that can fulfill this order line is expected. This date takes into account PO layering, where previously-backordered items will be fulfilled from new PO receipts, prior to new backordered lines. This means that the next purchase order due to be received may not be the purchase order to fulfill this line. Numeric, 6 positions (in user date format); display-only. |

|

Reserve date/time |

The date and time that inventory was matched to this order detail line. Numeric, 6 positions (in user date format, HHMMSS format); display-only. |

|

Ordered |

The number of units of this item on the order detail line. Numeric, 5 positions; display-only. |

|

Reserved |

The number of units of the item reserved during the Reservation program. This program reserves stock for specific orders. Quantities may or may not have picks created for them. Numeric, 5 positions; display-only. |

|

Printed |

The number of units of the item, on this order detail line, for which pick slips have been printed. Numeric, 5 positions; display-only. |

|

Shipped |

The quantity on this order detail line that has been shipped. Numeric, 5 positions; display-only. |

|

Canceled |

The quantity on this order detail line that has been canceled. Numeric, 5 positions; display-only. |

|

Returned |

The quantity on this order detail line that has been returned. Numeric, 5 positions; display-only. |

|

Sold out |

The quantity on this order detail line that has been sold out. Numeric, 5 positions; display-only. |

Work with Reservations by Warehouse Screen

Purpose: Use this screen to review reservation information by warehouse. This information is listed according to the item's quantity available to sell, the item's quantity that cannot be reserved except through interactive reservation, and the number of units of this item that will be reserved.

How to display this screen: Select Reserve by Warehouse for a detail line on the Work with Order Detail Reservations Screen.

| Field | Description |

|---|---|

|

Order |

A unique number assigned by the system to identify an order. Every order on the system is assigned an order number. Numeric, 8 positions; display-only. |

|

Ship-to number (Unlabeled field to the right of the order number) |

A hyphen (-) separates this field from the Order # field. Indicates the number of shipping addresses for the order. The system assigns a sequential ship-to number to every order. The first ship-to address is assigned the number 1. Numeric, 3 positions; display-only. |

|

Line number (Unlabeled field to the right of the ship-to number) |

A hyphen (-) separates this field from the Ship-to number. The line number on the order. Up to 999 detail lines may be entered on an order. Order lines are presented in descending sequence so that the most recent order line displays first. Numeric, 3 positions; display-only. |

|

Qty open (Quantity open) |

The total number of units that have not been shipped. This includes quantity on backorder and quantity held. Future shipments and drop ships are not included in this number. Numeric, 5 positions; display-only. |

|

Qty rsrved (Quantity reserved) |

The quantity of the item that is set aside for existing orders. Increases by immediate and interactive reservation and decreases by confirmation or pick void/reprint. Numeric, 5 positions; display-only. |

|

Sold to |

The name of the customer who placed the order. Validated against the Customer Sold-to table. Alphanumeric, 15 positions (first name), 1 position (initial), 25 positions (last name); display-only. |

|

Item |

A code and description of the unit of inventory on an order detail line. If a SKUed item is displayed, the SKU information will also appear. Validated against the Item table. Alphanumeric, 12 positions; display-only. |

|

Whs (Warehouse) |

A code that represents the default warehouse. Warehouse codes are defined in and validated against the Warehouse table; see Creating and Maintaining Warehouses (WWHS). Numeric, 3 positions; optional. |

|

Warehouse name |

A description of the default warehouse. Alphanumeric, 12 positions; display-only. |

|

Quantity available |

The quantity of the item that is available to sell. A negative number indicates the item is backordered. Numeric, 7 positions; display-only. |

|

Quantity protected |

The quantity of the item that can be reserved only through Interactive Reservation where inventory is dispersed manually, as in the case of large wholesale orders or preferred mail order customers. The system uses this field to reserve the component items on a finished good work order if the Use Work Order Processing (E37) system control value is selected. See Finished Good Work Order Processing (WWOR). Numeric, 5 positions; display-only. |

|

Qty to reserve (Quantity to reserve) |

The number of units of this item to reserve for this order. Order Lines Flagged for Van Delivery If the ship via on the order line (or the ship via on the

order header if one is not defined for the order line) matches the

ship via defined in the Default Van Delivery Ship Via (L07) system

control value, the system prevents you from reserving against a warehouse

other than the reserve warehouse defined for the order line. In this

situation, if you try to enter a quantity to reserve against a warehouse

other than the one defined for the order line, the system displays

an error message: Numeric, 5 positions; required. |

| Screen Option | Procedure |

|---|---|

|

Display locations |

Select Display Locs for a warehouse to advance to the Display On Hand by Warehouse Screen. |

|

Review warehouse details |

Select Warehouse details for a warehouse to advance to the Display Item Warehouse Screen (Displaying Item Warehouse Details) |

|

Review order details |

Select Order Detail to advance to the Display Order Detail Reserve Information Screen. |

|

Review reserved lines |

Select Reserved Lines to advance to the Display Reserved Order Lines Screen. |

Display On Hand by Warehouse Screen

Purpose: This screen displays on-hand inventory for items in a particular warehouse location.

How to display this screen: At the Work with Reservations by Warehouse Screen, select Display Locs for the warehouse you want to view.

| Field | Description |

|---|---|

|

Warehouse |

A code that represents the default warehouse. Numeric, 3 positions; display-only. |

|

Item |

A code and description of the unit of inventory on the order detail line. If a SKUed item is displayed, the SKU information will also appear. Item: alphanumeric, 12 positions; display-only. SKU: alphanumeric, three 4-position fields; display-only. Description: Alphanumeric, 30 positions, display-only. |

|

Location |

A user-defined code that represents a warehouse location where merchandise is stored. The warehouse location code can consists of a zone/aisle/shelf/bin combination, or it can be any user-defined code. The location code prints on picks slips and reports. Example: The location A010201 indicates:

See Creating and Maintaining Locations (WLOC). Alphanumeric, 7 positions; display-only. |

|

On hand |

The actual on-hand quantity for the item in this warehouse location. Numeric, 7 positions; display-only. |

|

Printed |

The number of units currently “allocated” for this item in this warehouse location, determined by the number of picks generated for this location. When determining locations to reserve during Reservation, the system subtracts the printed quantity from the on-hand quantity in this location to determine the quantity available for Reservation. Numeric, 7 positions; display-only. |

Display Item Warehouse Screen (Displaying Item Warehouse Details)

Purpose: This screen displays detail information for items in a specified Item/SKU Warehouse.

How to display this screen: At the Work with Reservations by Warehouse Screen, select Warehouse details for the warehouse you want to view. All fields on this screen are display-only.

| Field | Description |

|---|---|

|

Item |

The item code. Alphanumeric, 12 positions; display-only. |

|

SKU |

A code that further identifies the item. Alphanumeric, three 4-position fields; display-only. |

|

Warehouse |

The code and description of the default warehouse. Numeric, 3 positions; display-only. |

|

Reservation freeze |

Indicates whether the item or SKU in this warehouse is frozen. Valid values are:

If an item or SKU warehouse is frozen:

|

|

Economic order qty |

The optimum ordering quantity for this item/SKU, based on a set of criteria such as: quantity, cost, etc. Used for inventory reporting purposes and by Purchasing. Numeric, 7 positions; display-only. |

|

Backorder qty |

The quantity of the item needed to fill existing orders, which must be fulfilled through PO receipts. Numeric, 7 positions; display-only. |

|

Protected qty |

The quantity of the item that can be reserved only through Interactive Reservation where inventory is dispersed manually, as in the case of large wholesale orders or preferred mail order customers. The system uses this field to reserve the component items on a finished good work order if Use Work Order Processing (E37) is selected in the System Control table. See Finished Good Work Order Processing (WWOR). Numeric, 5 positions; display-only. |

|

Min qty |

The minimum on-hand quantity for the item/SKU in this warehouse. Numeric, 7 positions; display-only. |

|

Reorder qty |

The quantity of the item that should be ordered when inventory reaches the minimum stock level (defined in the Min Qty field). Numeric, 7 positions; display-only. |

|

Max qty |

The maximum on-hand quantity for the item/SKU in this warehouse. Numeric, 7 positions; display-only. |

|

Reserve qty |

The quantity of the item/SKU that is set aside for existing orders. Increases by immediate, batch, or interactive reservation and decreases by confirmation or pick void/reprint. Numeric, 7 positions; display-only. |

|

On hand qty |

The actual on-hand quantity for the item in this warehouse location. Numeric, 7 positions; display-only. |

|

S/H reserve qty |

The quantity of this item in this warehouse that has been reserved and is undergoing some type of special handling, such as monogramming, hemming, etc. Increased by the Reservation program. Items that are flagged with a special handling code in Order Entry or Order Maintenance increment this field following reservation. Decreased by Confirmation or Pick Void/Reprint. Numeric, 7 positions; display-only. |

|

On order qty |

The quantity of this item due to be received in this warehouse through purchase orders. This information helps the customer decide whether to order now or to cancel the order because of inventory unavailability. Numeric, 7 positions; display-only. |

|

Reserve transfer quantity |

The quantity of the item that is earmarked for an inventory transfer. This quantity cannot be used by the Reservation program to match inventory to new orders. Numeric, 7 positions; display-only. |

|

Protect min/max |

This field is not currently implemented. Included only if the Use Store File (G15) system control value is selected. |

|

Cost of goods |

Represents the vendor cost at which this item in this warehouse was purchased. The cost of the item is updated when the item is confirmed for shipment. Used in item profitability analyses. Note: The Display Cost in Inventory (A38) secured feature controls the display of this field.Numeric, 20 positions with a 2-place decimal; display-only. |

|

Picks generated |

The total number of pick slips generated for this item in this warehouse, life-to-date. Numeric, 7 positions; display-only. |

|

Dollars returned |

The dollar value of all returns that have been entered to date for this item in this warehouse. Updated by the Return Authorization process when the return is accepted. Updated with the actual dollars returned based on the amount charged when the item was shipped. Numeric, 20 positions with a 2-place decimal; display-only. |

|

Units returned |

The number of units of this item in this warehouse returned to date. Updated by the Return Authorization process when returns are entered and updated. Numeric, 7 positions; display-only. |

|

Dollars sold |

The actual amount sold (shipped and billed) for this item/SKU to date. Updated with the actual merchandise amount billed on the shipment, during Billing. Numeric, 20 positions with a 2-place decimal; display-only. |

|

Units sold |

The number of sales for this item/SKU in this warehouse to date. Updated during Billing. Numeric, 7 positions; display-only. |

|

Protect price |

This field is not currently implemented. Included only if the Use Store File (G15) system control value is selected. An error message indicates if you try to change

this value and you do not have authority to the Maintain Item Warehouse Retail Price (A91) secured feature: |

Display Reserved Order Lines Screen

Purpose: This screen displays order line information. This information is listed according to company; warehouse; quantity reserved, quantity printed, and quantity remaining; and reservation date and time.

How to display this screen: At the Work with Reservations by Warehouse Screen, select Reserved Lines.

| Field | Description |

|---|---|

|

Order |

A unique number assigned by the system to identify an order. Every order on the system is assigned an order number. Numeric, 8 positions; display-only. |

|

Ship-to number (Unlabeled field to the right of the order number) |

A hyphen (-) separates this field from the Order # field. Indicates the number of shipping addresses for the order. The system assigns a sequential ship-to number to every order. The first ship-to address is assigned the number 1. Numeric, 3 positions; display-only. |

|

Line number (Unlabeled field to the right of the ship-to number |

A hyphen (-) separates this field from the Ship-to field. The line number on the order. Up to 999 detail lines may be entered on an order. Order lines are presented in descending sequence so that the most recent order line displays first. Numeric, 3 positions; display-only. |

|

Qty ordered |

The number of units of this item ordered on this order line. Numeric, 5 positions; display-only. |

|

Qty reserved |

The quantity of the item/SKU that is set aside for this order. Numeric, 7 positions; display-only. |

|

Cmp (Company) |

The company for which you are viewing records. Numeric, 3 positions; display-only. |

|

Whs (Warehouse) |

A code that represents the warehouse from which the order line was reserved. Validated against the Warehouse table. Numeric, 3 positions; display-only. |

|

Quantity reserved |

The quantity of the item/SKU that is set aside for this order. Numeric, 7 positions; display-only. |

|

Quantity printed |

The number of units for which a pick slip has been printed. The system updates this field when it creates a pre-generated pick for the order line, incrementing this number by the quantity on the Pick Control Detail; see Applying Pick Slip Preparation to an Order. Numeric, 5 positions; display-only. |

|

Quantity remaining |

The difference between the quantity reserved and the quantity printed. The system updates this field when it creates a pre-generated pick for the order line, decreasing this number by the quantity on the Pick Control Detail; see Applying Pick Slip Preparation to an Order. Only records with a remaining quantity greater than zero will be selected. Numeric, 5 positions; display-only. |

|

Reservation date |

The date the item on the order detail line was reserved. Numeric, 6 positions (in user date format); display-only. |

|

Reservation time |

The time the item on the order detail line was reserved. Numeric, 6 positions (HHMMSS format); display-only. |

Scan Orders by Customer Class Screen

Purpose: Use this screen to display the customer(s) that you want to work with. Customer classes restrict certain customers from immediate reservation. For example, there may be some customers who should not be included in immediate reservation due to the volume of merchandise ordered, or the type of items ordered.

How to display this screen: On the Interactive Reservation Screen, enter the customer class you wish to work with, or prompt click on the arrow in the Customer class field to display a list of customer classes.

| Field | Description |

|---|---|

|

Order # |

A system-assigned code that represents a customer order number. Numeric, 8 positions; optional. |

|

Order date |

The order processing date. Defaults to the current date. Numeric, 6 positions (in user date format); optional. |

|

Status |

The status of the order detail line. Valid values:

Optional. |

|

Type |

A user-defined code that indicates how the order was received, such as mail order, telephone order, retail, etc. Alphanumeric, 1 position; optional. |

Select Work with detail for an order to advance to the Work with Order Detail Reservations Screen.

Work with Reservations by Item/SKU Screen

Purpose: Use this screen to display the order information for a particular item that you want to work with.

How to display this screen: On the Interactive Reservation Screen, enter an item/SKU, or prompt click on the arrow in this field to display a list of items and then a list of SKUs associated with an item.

| Field | Description |

|---|---|

|

Item |

A code and description for a unit of inventory on an order detail line. If a SKUed item is displayed, the SKU information will also appear. Alphanumeric, 12 positions; display-only. |

|

COLR SIZE OTHR |

The SKU code; a code that further defines the item. The three elements are defined in the System Control table and validated against the SKU Element (1, 2, 3) tables. Alphanumeric, three 4-position fields; display-only. |

|

Qty avail (Quantity available) |

The quantity of the item that is available to sell in all warehouses. A negative number indicates the item is backordered. The calculation for availability is:

Takes into account only reservable locations. Numeric, 7 positions; display-only. |

|

Qty prot (Quantity protected) |

The quantity of the item that can be reserved only through Interactive Reservation where inventory is dispersed manually, as in the case of large wholesale orders or preferred mail order customers. The system uses this field to reserve the component items on a finished good work order if Use Work Order Processing (E37) is selected in the System Control table. See Finished Good Work Order Processing (WWOR), for more information on work orders. Numeric, 5 positions; display-only. |

|

Order # |

A unique number assigned by the system to identify an order. Numeric, 8 positions; optional. |

|

Shp (Ship-to number) |

This system-assigned number represents the number of shipping addresses for the order. Numeric, 3 positions; optional. |

|

Ln # (Line number) |

A system-assigned detail line number on the order. Numeric, 3 positions; optional. |

|

Sold-to name |

The name of the customer who placed the order. Validated against the Customer Sold-to table. Alphanumeric, 15 positions (first name), 1 position (initial), 25 positions (last name); display-only. |

|

Qty open |

The number of units of this item that have not shipped. |

|

Qty rsrvd (Quantity reserved) |

The number of units of the item that are set aside for existing orders. Increases by immediate and interactive reservation and decreases by confirmation or pick void/reprint. Numeric, 5 positions; optional. |

|

Qty to reserve |

The number of units of this item that are to be reserved for this order. Numeric, 5 positions; required. |

| Screen Option | Procedure |

|---|---|

|

Display order detail information |

Select Display order detail for an order to advance to the Display Order Detail Reserve Information Screen. |

|

Display reservations by warehouse details information |

Select Reserve by warehouse for an order to advance to the Work with Reservations by Warehouse Screen. |

|

Display reserved order lines |

Select Reserved order lines for an order to advance to the Display Reserved Order Lines Screen. |

Selecting Vendors for Drop Ship Processing (MDSP)

Overview: Use Select Vendors for Drop Ship Processing to select one, several, or all vendors for processing drop ship purchase orders or picks. Each vendor code entered on the screen is validated against Working with Vendors (WVEN). If you do not select any vendors, all vendors are eligible for drop ship processing. Completing this screen automatically generates drop ship purchase orders, pick slips, the Pick Message from Order Management System (CWPickOut), or invoices; also, if the vendor is flagged to use the Order Broker Drop Ship Integration, the drop ship purchase order is automatically sent to Order Broker. See Drop Ship Processing for a process overview.

Drop ship items are items that you do not stock in inventory. When a customer places an order for a drop ship item, you order the item from your supplier (vendor). The vendor ships the item directly to your customer.

Generating drop ship pick slips by batch: You can generate drop ship pick slips by batch for selected vendors using Processing Drop Ship Orders by Batch (MDSB); however, you cannot generate drop ship purchase orders through that menu option. Batch processing of drop ship pick slips is available only for vendors whose Drop ship output field is set to Drop Ship Pick.

Scheduling drop ship orders: You can use the Drop Ship Processing DSHPROC periodic function (program name FLRDSHP ) to schedule drop ship order processing for all drop ship purchase orders or pick slips. See Scheduling Jobs for more information.

Quotes: Drop ship items on quotes are not eligible for drop ship processing until the quote is converted to an order; see Entering Pre-Order Quotes for an overview and required setup.

Emailing drop ship purchase orders not available: Regardless of the setting of the Email Purchase Order (K80) system control value, sending drop ship purchase orders by email is not supported. See that system control value for more information.

Bypassing printable pick slips not available: Even if the Bypass Creation of Pick Forms during WSPS Pick Generation (K55) system control value is selected, the Select Vendors for Drop Ship Processing option still creates printable pick slips for eligible vendors. This system control value controls the generation of printable pick slips only when you use the Streamlined Pick Slip Generation (WSPS) option.

Submitting ship-for-pickup orders to the Order Broker: If an order originating in Order Management System that is selected for drop ship processing is flagged to ship to a store location for customer pickup, the process sends a Submit Order request to the Order Broker. See Ship-for-Pickup Orders for an overview.

Checking status for retail pickup or delivery orders: If a retail pickup or delivery order from the Order Broker is selected for drop ship processing, the process sends a status inquiry request to the Order Broker to confirm that the order has not been canceled since the last update on its status was received. See Retail Pickup (including Ship-for-Pickup) or Delivery Orders for an overview.

Drop ship authorization records in W status? Pick slip generation displays an error message if there are drop ship authorizations in W status. See DROPSHIP Authorization Records in W Status for a discussion.

In this topic:

Select Vendors for Drop Ship Screen

Purpose: Use this screen to select vendors for drop ship processing and also to select whether to print drop ship purchase orders or generate the Pick Message from Order Management System (CWPickOut).

How to display this screen: Enter MDSP in the Fast path field at the top of any menu, or select Select Vendors for Drop Ship Picks from a menu.

| Field | Description |

|---|---|

|

Vendors |

A code that defines the supplier of an item. Validated against the Vendor table; see Working with Vendors (WVEN). To select one or more vendors, enter the vendor number(s); otherwise, to select all vendors, leave the vendor fields blank. Numeric, 7 positions; optional. |

|

Print drop ship purchase orders |

Indicates whether the system prints drop ship purchase orders for the vendors specified in the Vendor field. You can select the sort sequence in which the drop ship purchase orders print. The sort option used previously defaults. Valid values are:

Setup: Drop ship purchase orders print only for vendors whose Drop ship output field on the second Vendor screen is set to Drop ship purchase order . Drop ship pick slip/invoice: When you print a drop ship purchase order, the system also prints a Drop Ship Pick Slip/Invoice. If a vendor’s Drop ship output field is set to Drop ship pick , the system prints a drop ship pick slip/invoice instead of a drop ship purchase order. To print: See Possible Drop Ship Output for information on how to print drop ship purchase orders or pick slips/invoices. PO download trigger: The system creates a purchase order download Add trigger record when the purchase order is printed. Alphanumeric, 1 position; required. |

|

Fax invoices/picks to vendors |

Indicates whether the drop ship pick slips/invoices should be faxed to the vendor instead of, or in addition to, printing. This option is not currently implemented. |

| Screen Option | Procedure |

|---|---|

|

Continue to process drop ships, even if there is a pick slip generation error |

Select Accept. The system sends all records in the CC Authorization Transaction table to the Authorization Service, including the authorization associated with the non-drop ship order. See Drop Ship Processing for an overview of how to handle any errors. |

|

Return to Drop Ship Processing without processing drop ships |

Select Reject. You return to the Select Vendors for Drop Ship Screen so you can correct any pick slip generation error before processing drop ships. See Drop Ship Processing for an overview of how to handle any errors. |

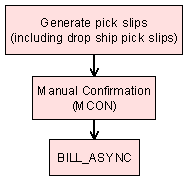

Drop Ship Processing

The system performs the following procedures during drop ship processing:

| # | Step |

|---|---|

|

1. |

An order is flagged as “Drop Ship” in order entry because it includes a drop ship item. |

|

2. |

The system checks the Item/SKU to determine the primary vendor assigned to the item/SKU that was ordered. |

|

3. |

The system processes credit card authorizations on the drop ship orders, if needed. The setting of the Authorize Only Merchandise for Drop Ship (C92) system control value determines the amount to authorize. Any orders whose credit cards are declined for authorization are not included in the drop ship process; see Using the Credit Card Authorization Interface. Note: If you process drop ships for all vendors, the system requests a single authorization for an order; however, if you process drop ships for selected vendors, the system requests a separate authorization for each vendor associated with a drop ship item on an order. |

|

4. |

The system then checks the Vendor table to see if the Drop ship output field on the second Vendor screen is set to Drop ship pick, Drop ship purchase order, or OROB drop shipping (Order Broker’s Supplier Direct Fulfillment module). If the Drop ship output field for the vendor is set to: Drop ship purchase order , the system generates a Purchase Order AND a Drop Ship Pick Slip/Invoice. Once the vendor confirms the order, you can confirm the shipment manually, using the Purchase Order Receipts menu option. Drop ship pick, the system generates a Drop Ship Pick Slip/Invoice or the Pick Message from Order Management System (CWPickOut). Once the vendor confirms the order, you can confirm the shipment manually, using the Manually Confirming Shipments (MCON) menu option. The system then produces the Drop Ship Batch Confirmation Report, which allows you to review the total costs of items on the drop ship pick slips. See Possible Drop Ship Output for an overview of output options. OROB drop shipping , the system automatically sends the drop ship purchase orders to Order Broker’s Supplier Direct Fulfillment module for processing. See Interface with Order Broker’s Supplier Direct Fulfillment Module: Overview and Setup for background. The system also:

|

|

5. |

The system produces several reports related to drop ship processing; see Reports. |

Note:

A drop ship order line is not eligible for processing until the current date plus the number of Lead days on the Create Vendor Item Screen equals or exceeds the Arrival date for the order line.Example: On October 1, you enter an order for a drop ship item supplied to your customers by vendor 789. At the customer’s request, you enter an Arrival date of December 15 . The vendor item’s specified number of Lead days is 10. The order line is not eligible for processing until December 5.

PICKGEN auth records in W status: A pop-up window opens when you process drop ships if the system finds a pick control header record with a pick status of W (waiting for authorization) for a non-drop ship order paid with a credit card was not authorized during a previous pick slip generation process due to transmission failure.

The system creates a record in the Pick Control Header table when you generate pick slips. The pick control header record remains in a W pick status until the corresponding authorization transaction in the CC Authorization Transaction table receives an approved authorization. A pick slip is not produced until the credit card on the order receives an approved authorization.

When you see this pop-up window during drop ship processing, you can either:

- select Accept to generate drop ship orders without first re-sending

the authorization transaction associated with the pick control header

record in a W pick status for authorization. When you perform drop

ship processing, the system sends all authorization records in the

CC Authorization Transaction table to the authorization service for

authorization, including the authorization transaction associated

with the pick control header record in a W status. If you do this,

a record remains in the Pick Control Header table for the non-drop

ship order, but the corresponding authorization record no longer exists

in the CC Authorization Transaction table. To generate a pick slip

for the order, you need to delete the record from the Pick Control

Header table and generate pick slips again.

Note:

When you generate pick slips again, the system sends an authorization transaction to the authorization service for the order that was stranded in the Pick Control Header table. You need to make sure that you do not receive a double authorization for the order since the authorization transaction associated with the order was sent to the authorization service when you performed drop ship processing.

Note:

You will continue to see this pop-up window when you process drop ships until you delete the record in the Pick Control Header table.- select Reject to return to the Select Vendors for Drop Ship Screen without

processing drop ships. You can verify with the authorization service

whether the authorization associated with the pick control header

record in a W status was received.

- If the authorization was received by the authorization service, use the Reprocess Authorizations Screen (RPAA) to receive the authorization response. If the order receives an approved authorization, the system generates the pick slip and updates the record in the Pick Control Header table to a Z (authorized) or M (submitted to PC Manifest) status.

- If the authorization was not received by the authorization service,

check the CC Authorization Transaction table to verify that only the

authorization transaction for the order exists. Then, use the Reprocess Authorizations Screen (RPAA) to resend

the authorization transaction for authorization. If the order receives

an approved authorization, the system generates the pick slip and

updates the record in the Pick Control Header table to a Z (authorize)

or M (submitted to PC Manifest) status.

Note:

If authorization transactions exist in the CC Authorization Transaction table for drop ship orders, the system sends the authorization transactions to the authorization service when you reprocess authorizations.

Possible Drop Ship Output

Depending on setup, the system can generate a printed copy of a Purchase Order, a Drop Ship Pick Slip/Invoice, or the Pick Message from Order Management System (CWPickOut), or various combinations. The conditions required to produce each type of output are described below. Also, if the vendor meets the conditions for more than one type of output, the system produces all qualifying output types. For example, if the vendor meets the conditions to print both drop ship purchase orders and pick slips/invoices, then all four outputs are produced.

The system prints a drop ship PO when:

- the vendor’s Drop ship output field is Drop ship purchase order , and

- the vendor’s Print PO field is selected , and

- the Print drop ship purchase orders field at the Select Vendors for Drop Ship Screen is set to Vendor print or Purchase order print.

The system prints a drop ship pick slip/invoice when:

- the system prints a drop ship PO (see above for the requirements).

- the vendor’s Drop ship output field is Drop ship pick or OROB drop shipping .

A separate drop ship pick slip/invoice prints for each ship-alone item if the Print One Drop Ship Invoice per Ship Alone Item (E38) system control value is selected ; however, this system control value does not apply to drop ship purchase orders sent to Order Broker.

The system also creates pick download triggers (File code of PCH ) in the IL Outbound Trigger table when you generate a drop ship pick slip/invoice if the Create Generic Pick Download Triggers (I31) system control value is selected . The PICK_OUT process in Working with Integration Layer Processes (IJCT) generates the Pick Message from Order Management System (CWPickOut) for each of these trigger records.

Note:

The system deletes the drop ship pick slip/invoice once the associated drop ship purchase order is closed or cancelled and all IL Outbound Trigger records (WOIT) for the purchase order and drop ship pick slip/invoice are in an X Closed status.Multiple items? The Allow Only Single Line on Drop Ship Pick (C82) system control value controls whether to include multiple items on a drop ship pick slip, or to generate separate pick slips; similarly, the Allow Only Single Line on Drop Ship PO (M13) controls whether to include multiple items on a drop ship purchase order, or to generate multiple purchase orders. See each system control value for more information.

Reports

The system produces the following reports during drop ship processing:

- Vendor Drop Ship Worksheet: Generated whenever you run drop ship processing.

- Drop Ship Purchase Order List: Generated when you process drop ship purchase orders. This list does not include drop ship pick slips.

- Drop Ship Pick Slip/Invoice: Generated when you process drop ship pick slips. The system also generates a drop ship pick slip/invoice when you generate drop ship purchase orders.

- Purchase Order: Generated for drop ship purchase orders when you enter Purchase order print or Vendor print in the Print drop ship purchase orders field on the Select Vendors for Drop Ship screen.

- Declined Drop Ships: Generated whenever you run drop ship processing.

- Credit Card Authorization Listing: Generated for drop ship orders requiring credit card authorization.

- Address Verification Response List: Generated for drop ship orders requiring credit card authorization and AVS verification.

Print program: The system uses the Drop Ship Pick Print Program (E92). If this system control value is blank, the system uses the Pick Printing Program (C37). The standard pick slip printing program name is PICKG (graphical form).

Active procedure: When you accept you entries at this screen, the system creates an active procedure so that another user cannot process drop ship orders while the program is already running. A second batch job will be aborted if it is submitted while the first batch job is active.

Displaying Pick Slip Generation Inquiry (DPSI)

Purpose: Display Pick Slip Generation Inquiry is a management tool that allows you to monitor warehouse performance and pick slip generations. This option provides a detailed listing of the picks that have been generated and their current status.

Pre-printed pick slips: Display Pick Slip Generation Inquiry does not include pick slips in a pre-printed status (G Generated No Authorization or H Generated Has Authorization); see Creating Pre-Generated Picks.

In this topic:

- Display Pick Slip Generation Inquiry Screen

- Display Picks for Batch Screen

- First Display Pick Control Header Screen

- Second Display Pick Control Header Screen

- Work with Pick Details Screen

- Display Pick Control Details Screen

- Display Pick Locations Screen

Display Pick Slip Generation Inquiry Screen

How to display this screen: Enter DPSI in the Fast path field at the top of any menu or select Display Pick Slip Generation Inquiry from a menu.

| Field | Description |

|---|---|

|

Date |

The date the pick slip was printed. This is the date for the first pick slip in the batch sorted in cart batch number, pick control number sequence. Numeric, 6 positions (in user date format); display-only. |

|

Time |

The time the pick slip was printed. This is the time for the first pick slip in the batch sorted in cart batch number, pick control number sequence. Numeric, 6 positions (HHMMSS format); display-only. |

|

Billing batch |

A system-generated batch number that is assigned to each pick slip run. Numeric, 7 positions; optional. |

|

Pick # range |

Each pick slip is assigned a number; this field displays the range of pick slip numbers that were picked. Numeric, 3 positions; display-only. |

|

Total printed |

The total number of pick slips that were printed, for each date. Numeric, 3 positions; display-only. |

|

Cnfrm (Confirmed) |

The total number of pick slips that were shipped and billed, for each date. This is the number of pick slips that are in a Confirmed (C) status. Numeric, 3 positions; display-only. |

|

Packd (Packed) |

The total number of pick slips that were packed. This is the number of pick slips that are a Packed (P) status. Numeric, 3 positions; display-only. |

|

Void |

The total number of pick slips that were voided. This is the number of pick slips that are in Void (V) status. Numeric, 3 positions; display-only. |

|

Suspd (Suspended) |

The total number of pick slips that have been suspended. This is the number of pick slips that are in a Suspended (S) status. Numeric, 3 positions; display-only. |

|

Outsd (Outstanding) |

The total number of pick slips that have been printed, but not yet confirmed. This is the number of pick slips that are in a Manifest (M) or Carryover (O) status. Numeric, 3 positions; display-only. |

| Screen Option | Procedure |

|---|---|

|

Display picks |

Select Display Picks for a pick to advance to the Display Picks for Batch Screen. |

Display Picks for Batch Screen

Purpose: Use this screen to review pick information including the batch number, pick number, printed/confirmed date, and the status of the pick.

How to display this screen: Select Display Picks for a pick at the Display Pick Slip Generation Inquiry Screen.

| Field | Description |

|---|---|

|

Billing batch # |

A system-generated batch number that is assigned to each pick slip run. Numeric, 7 positions; display-only. |

|

Pick # |

The system-assigned control number for this pick. Numeric, 7 positions; display-only. |

|

Printed |

The date the pick was printed. Numeric, 6 positions (in user date format); display-only. |

|

Confirmed |

The date the pick was shipped and billed. Numeric, 6 positions (in user date format); display-only. |

|

Status |

The status of this pick. Valid values:

Optional. |

|

Reprint |

The pick control number that has been reprinted. Numeric, 7 positions; display-only. |

| Screen Option | Procedure |

|---|---|

|

Display pick control header information |

Select Display for a pick to advance to the First Display Pick Control Header Screen. |

|

Work with pick details |

Select Details for a pick to advance to the Work with Pick Details Screen. |

First Display Pick Control Header Screen

Purpose: Use this screen to review complete pick information including the control and billing batch numbers, pick status, generation type, date/time for last update, confirmation, printing, number of labels, cartons, zones, warehouse, and drop points.

Select OK at this screen to advance to the Second Display Pick Control Header Screen, where you can review additional pick control header information.

How to display this screen: Select Display for a pick at the Display Picks for Batch Screen.

| Field | Description |

|---|---|

|

Control # |

The control number assigned to a batch of picks. Numeric, 7 positions; display-only. |

|

Billing batch # |

A system-generated batch number that is assigned to each pick slip run. Numeric, 7 positions; display-only. |

|

Pick status |

The description of the pick's status. Valid values:

Display-only. |

|

Generation type |

The type of pick slip being generated. Valid values:

Display-only. |

|

Date/time last update |

The date and time this pick was last changed. Printing the pick is considered to be a change. Numeric, 6 positions (in user date format, HHMMSS format); display-only. |

|

By |

The process that created the Pick Control Header record. From the Last update by user field in the Pick Control Header table. See Creating Pre-Generated Picks for a list of processes. Alphanumeric, 10 positions; display-only. |

|

Date/time printed |

The date and time this pick was printed. Numeric, 6 positions (in user date format, HHMMSS format); display-only. |

|

# of labels |

The total number of labels printed for this pick slip. Used in the following situations:

Numeric, 3 positions; display-only. |

|

# of labels scanned |

The total number of shipping labels scanned, or wanded, for this pick. Numeric, 3 positions; display-only. |

|

Cart batch # |

The system-assigned number that represents the batch pick slip list for each cart. If the system determines that there is not enough bins in the cart to accommodate the batch, a new cart/batch number is created. Numeric, 3 positions; display-only. |

|

# of cartons |

The number of cartons required to ship each order. Determined by the Cubing feature. Numeric, 3 positions; display-only. |

|

Pick zones (1-6) |

The warehouse zone(s) on this pick slip. The System Control table value, Maximum Number of Zones (B41), defines the maximum number of zones (up to 6) on a pick slip. Example of how pick zones are used: A pick slip with items to be picked in zones A, B, and D will not be included in the same batch as a pick slip with items to be picked in zones A, B, and R. However, a pick slip with items to be picked in zones A, B, and D will be included in the same batch as a pick slip with items to be picked in zones A and D. Numeric, 3 positions; display-only. |

|

Include on S/J |

|

|

# of lines |

The number of items on the pick slip. Numeric, 3 positions; display-only. |

|

Ship via |

The code that represents the carrier for this order. Validated against the Ship Via table. Numeric, 2 positions; display-only. |

|

Hazard code |

A user-defined code used to categorize an item as a hazardous material that requires special storage and/or handling. Validated against the Item Hazard table; see Working with Hazardous Item Codes (WHAZ). This information is passed to TanData. Numeric, 2 positions; display-only. |

|

Warehouse |

A code that represents the default warehouse. Validated against the Warehouse table. Numeric, 3 positions; display-only. |

|

Drop point |

A code that represents a location to which merchandise will be shipped from your warehouse.

Numeric, 3 positions; display-only. |

Second Display Pick Control Header Screen

Purpose: Use this screen to review additional pick information, such as the order number and customer information.

How to display this screen: Select OK at the First Display Pick Control Header Screen.

| Field | Description |

|---|---|

|

Control # |

The control number assigned to this batch of picks. Numeric, 7 positions; display-only. |

|

Reprinted control # |

The control number assigned to the batch of picks that have been reprinted. Numeric, 7 positions; display-only. |

|

Merch |

The total value of merchandise. A total of the item price multiplied by the quantity ordered and does not include freight, additional charges, tax, or handling. Numeric, 20 positions with a 2-place decimal; display-only. |

|

Freight |

The total charge for shipping an order. Does not include any additional charges associated with shipping the order. Based on the freight method defined for the source code on the order. The total may depend on the quantity or weight of items ordered, or on the dollar value of the order as a whole. Numeric, 20 positions with a 2-place decimal; display-only. |

|

Add’l freight |

The total dollar value for additional freight charges, above the order's regular shipping charges. The total of the additional freight charges defined for the shipper(s). Additional freight charges are defined in the Ship Via table. Numeric, 20 positions with a 2-place decimal; display-only. |

|

Add’l chgs |

The total extra charges added to the order. Additional charges can be:

Numeric, 20 positions with a 2-place decimal; display-only. |

|

Handling |

The total charge for special handling or gift wrapping. The full total of the handling charges for each item multiplied by the quantity ordered. The SKU/Offer table controls whether the item is eligible for special handling and the charge for special handling. Numeric, 20 positions with a 2-place decimal; display-only. |

|

Tax |

The total sales tax on the order. Based on the merchandise value. The system calculates sales tax for the order by multiplying the merchandise amount by the tax rate for the shipping destination. See Entering Orders for additional information. Numeric, 20 positions with a 2-place decimal; display-only. |

|

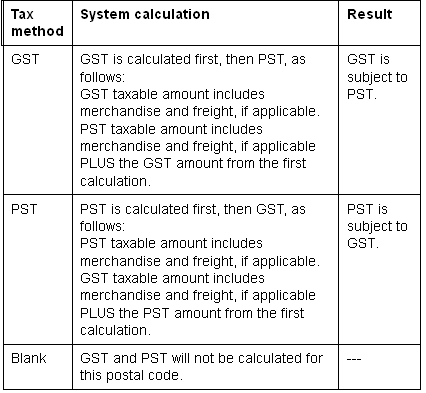

GST |

Canadian Goods and Services tax. A tax method is defined for each postal code to accommodate the varying tax requirements in each province, when shipping from Canada. Numeric, 20 positions with a 2-place decimal; display-only. |

|

PST |

Provincial Services tax. A tax method is defined for each postal code to accommodate the varying tax requirements in each province, when shipping from Canada. Numeric, 20 positions with a 2-place decimal; display-only. |

|

Paid |

The amount paid by the customer. Numeric, 20 positions with a 2-place decimal; display-only. |

|

Total order |

The sum of all charges including merchandise, freight, additional freight, tax, handling, and additional charges. Numeric, 20 positions with a 2-place decimal; display-only. |

|

Due |

The balance due. If this is a credit, the system displays the amount with CR beside the value. The amount due is calculated by subtracting the Paid amount from the Total Order amount. Numeric, 20 positions with a 2-place decimal; display-only. |

|

PO # |

The customer's purchase order number. Alphanumeric, 15 positions; display-only. |

|

Order # |

A unique number assigned by the system to identify an order. Every order on the system is assigned an order number. Numeric, 8 positions; display-only. |

|

Customer # |

A unique number assigned by the system to identify a customer. Every customer on the system is assigned a customer number. Numeric, 9 positions; display-only. |

|

Name |

The name of the customer who placed the order. Alphanumeric, 15 positions (first name), 1 position (initial), 25 positions (last name); display-only. |

|

Company name |

The name of the company that placed the order. Alphanumeric, 30 positions; display-only. |

|

Address |

The customer's street address. Alphanumeric, 32 positions; display-only. |

|

Apartment |

The customer's apartment, suite, rural route, or floor number. Alphanumeric, 10 positions; display-only. |

|

City/St/Postal/ Cntry |

The city, state, postal zip code, and country where the customer receives mail or shipping. State codes are defined in and validated against the State table, which is accessible through the Work with Countries menu option; see Setting Up the Country Table (WCTY). Alphanumeric, 25 positions (city), 2 positions (state), 10 positions (postal code), 3 positions (country); display-only. |

|

Delivery code |

Identifies whether the customer is Business or Residential. Used to determine shipping charges. Valid values:

Display-only. |

|

PO box? |

Indicates whether the shipper will deliver packages to a post office (P.O.) box. Any address in which P.O. Box or APO/FPO appears must be delivered to a post office box.

|

| Screen Option | Procedure |

|---|---|

|

Display detail lines |

Select Display Detail Lines to advance to the Work with Pick Details Screen. |

Work with Pick Details Screen

Purpose: Use this screen to review the line number, item and SKU information, and the quantity printed.

How to display this screen: Select Detail Lines at the First Display Pick Control Header Screen or the Second Display Pick Control Header Screen.

| Field | Description |

|---|---|

|

Line # |

A system-assigned detail line number on the order. Up to 999 detail lines may be entered on an order. Order lines are presented in descending sequence so that the most recent order line displays first. Numeric, 3 positions; display-only. |

|

Item |

A code that represents a unit of inventory on an order detail line. Alphanumeric, 12 positions; display-only. |

|

SKU |

A code that further identifies the item. Alphanumeric, three 4-position fields; display-only. |

|

Quantity printed |

The number of units of the item printed and the quantity which should be shipped. Numeric, 5 positions; display-only. |

| Screen Option | Procedure |

|---|---|

|

Display pick control details |

Select Display for a line to advance to the Display Pick Control Details Screen. |

|

Display pick locations |

Select Locations for a line to advance to the Display Pick Locations Screen. |

Display Pick Control Details Screen

Purpose: Use this screen to review the pick control details for each order line.

How to display this screen: Select Display for an order line on the Work with Pick Details Screen.

| Field | Description |

|---|---|

|

Order # |

A unique number assigned by the system to identify an order. Every order on the system is assigned an order number. Numeric, 8 positions; display-only. |

|

Ship-to # |

Indicates the number of shipping addresses for the order. The system assigns a sequential ship-to number to every order. The first ship-to address is assigned the number 1. Numeric, 3 positions; display-only. |

|

Seq # (Sequence number) |

A number assigned to a warehouse location and used to verify the location number that is either entered, scanned, or system-loaded. Numeric, 3 positions; display-only. |

|

Control # |

The control number assigned to a pick slip. Numeric, 7 positions; display-only. |

|

Line # |

The line number on the order. Up to 999 detail lines may be entered on an order. Order lines are presented in descending sequence so that the most recent order line displays first. Numeric, 3 positions; display-only (assigned by the system). |

|

Item |

A code that represents a unit of inventory on the order detail line. Alphanumeric, 12 positions; display-only. |

|

SKU |

A code that further identifies the item. Alphanumeric, three 4-position fields; display-only. |

|

Original print qty |

The original quantity that was printed on the pick. This becomes important if the quantity on the pick is changed. Numeric, 5 positions; display-only. |

|

Qty printed |

The number of units of the item printed and the quantity which should be shipped. Numeric, 5 positions; display-only. |

|

Qty packed |

The number of units of the item packed and the quantity which should be shipped. Numeric, 5 positions; display-only. |

|

Qty ordered |

The number of units of the item ordered. Numeric, 3 positions; display-only. |

|

Qty B/O (Quantity backordered) |

The number of units of the item backordered. Numeric, 3 positions; display-only. |

|

Price |

The system price of a single unit of the item. The price is assigned by the system, but may be overridden in Order Entry. Numeric, 13 positions with a 2-place decimal; display-only. |

|

Extension |

The total price of the order. Calculated by multiplying the Unit Price by the Quantity Shipped. Numeric, 11 20 with a 2-place decimal; display-only. |

|

Special handling |

The charge for special handling a single unit of the item. The SKU/Offer table controls whether the item is eligible for special handling and the charge for special handling. Numeric, 13 positions with a 2-place decimal; display-only. |

|

Extension |

The total special handling charges for the order. Calculated by multiplying the Special Handling charge by the Quantity Shipped. Numeric, 20 positions with a 2-place decimal; display-only. |

|

Gift wrap |

The charge for gift wrapping a single unit of the item. The SKU/Offer table controls whether the item is eligible for gift wrapping and the charge for gift wrapping. Numeric, 13 positions with a 2-place decimal; display-only. |

|

Extension |

The total gift wrapping charges for the order. Calculated by multiplying the Gift Wrap charge by the Quantity Shipped. Numeric, 20 positions with a 2-place decimal; display-only. |

|

Freight |

The total charge for shipping an order. Does not include any additional charges associated with shipping the order. The system performs this calculation based on the freight method defined for the source code on the order. The total may depend on the quantity or weight of items ordered, or on the dollar value of the order as a whole. Numeric, 20 positions with a 2-place decimal; display-only. |

|

Tax |

The total sales tax on the order. Based on the merchandise value. The system calculates sales tax for the order by multiplying the merchandise amount by the tax rate for the shipping destination. See Setting Up the Zip/City/State (Postal Code) Table (WZIP) and Working with Customer Tax Status. Numeric, 20 positions with a 2-place decimal; display-only. |

|

GST (Canadian Goods and Services tax) |

A federal-level tax that may apply to orders within Canada. Numeric, 20 positions with a 2-place decimal; display-only. |

|

PST (Provincial Services tax) |

A province-level tax that may apply to orders within Canada. Numeric, 20 positions with a 2-place decimal; display-only. |

|

Line status |

The status of the order detail line. Valid values:

Alphanumeric, 1 position; display-only. |

|

Backorder control |

Specifies what action should be taken for this line. Valid values:

Alphanumeric, 1 position; display-only. |

|

Effect inventory (Effect on inventory) |

Indicates whether this order detail line affects the inventory count. For example, you may not want a mailer that is included in each shipment to be reflected in your actual inventory count.

|

|

Carton # |

The number assigned to the carton by the system. Numeric, 3 positions; display-only. |

|

Cart bin # |

The number assigned to the cart/bin by the system. Numeric, 3 positions; display-only. |

|

Requires special (Requires special handling) |

Indicates whether or not this order detail line requires special handling.

|

Display Pick Locations Screen

Purpose: Use this screen to review the warehouse, zone, location, quantity picked and cart batch information.

How to display this screen: Select Locations for an order line at the Work with Pick Details Screen.

| Field | Description |

|---|---|

|

Whs |

A code that represents the primary warehouse. Validated against the Warehouse table. Numeric, 3 positions; display only. |

|

Zone |

The zone(s) in the warehouse that is used for this pick slip. You can have up to 6 zones on a pick slip. The Maximum Number of Zones (B41) system control value defines the maximum number of zones on a pick slip. Numeric, 3 positions; display only. |

|

Location |

A code that represents a warehouse location where merchandise is stored. The warehouse location code can consist of a zone/aisle/shelf/bin combination, or it can be any user-defined code. The location code prints on picks slips and reports. Example: The location A010201 indicates:

Alphanumeric, 7 positions; display only. |

|

Qty picked |

The quantity of the item that has been picked from this warehouse. Numeric, 3 positions; display only. |

|

Cart batch |

The batch pick slip list that is assigned to each cart. Numeric, 3 positions; display only. |

Working with Pick Slip Messages (WPSM)

Purpose: The Work with Pick Slip Messages screen is used to create, change, delete, or display messages. Messages to be included on pick slips can be customer service messages, warehouse messages, gift messages, etc. The format of the message determines where the message will print.

In this topic:

Work with Pick Slip Messages Screen

How to display this screen: Enter WPSM in the Fast Path field at the top of any menu.

| Field | Description |

|---|---|

|

Message |

A code that represents the message. Alphanumeric, 2 positions; optional. |

| Screen Option | Procedure |

|---|---|

|

Create a new pick slip message |

Select Create to advance to the Create Pick Slip Message Pop-up Window. |

|

Change a pick slip message |

Select Change for the Opt field to advance to the Change Pick Slip Message window. At the Change window you can change any information except the Message number. See Create Pick Slip Message Pop-up Window for field descriptions. |

Create Pick Slip Message Pop-up Window

To create a pick slip message: At the Work With Pick Slip Message screen, select Create.

| Field | Description |

|---|---|

|

Message |

A code that represents the pick slip message. Numeric, 2 positions. Create screen: required. Change screen: display-only. |

|

Message text |

You can enter up to 3 lines of message text. This free-form message text will print on each pick slip. Alphanumeric, 40 positions (each line); required. |

Streamlined Pick Slip Generation (WSPS)

Purpose: Use streamlined pick slip generation to:

- Create and work with pick slip generation templates that determine the pre-generated picks to select for pick slip generation.

- To advance to the Display Operations Control Summary Screen.

- Generate pick slips for a selected pick slip generation template.

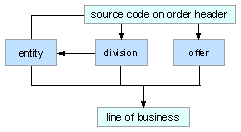

Pick slip generation options: Pick slip generation options define the criteria to use when selecting pre-generated picks for pick slip generation. You can select pre-generated picks for generation based on a specified:

- warehouse

- source category

- ship via

- pay type

- item

- status (H Generated Has Authorization status)

- order

- line of business

- location class

- arrival date range

- sold to customer

- state

- postal code range

- number of pick lines

In addition, you can select pre-generated picks for generation based on whether the associated order is flagged as a gift order, the pick contains a single line, or an item on the pick contains a special handling code, requires gift wrapping, or is flagged as oversized.

Generating pick slips: The system uses the pick slip generation options, system control values, and order information to create the pick slip. When you select Generate Picks for a pick slip generation template, the system submits a batch job (PICK_GEN) to perform batch authorization, allocate stock, sort the pick slips, and print the picking documents. See Performing Pick Slip Generation for an overview and processing details.

Bypass printable pick slips? You can expedite the pick slip generation process even further by omitting the generation of printable pick slips. To do so, select the Bypass Creation of Pick Forms during WSPS Pick Generation (K55) system control value. For example, you might select this option if you use the Generic Pick Out API to communicate with your warehouse management system and do not need to print pick slips. For more information see the Web Services Guide on My Oracle Support (ID 2149144.1). Also see the Bypass Creation of Pick Forms during WSPS Pick Generation (K55) system control value for a discussion of the differences in processing and print output when you omit printable pick slip generation.

Scheduling pick slip generation: You can schedule when pick slip generation runs for a particular pick slip generation template using a periodic function whose Program name is PFR0107 and whose Parameter matches the pick slip generation template’s Description. See Scheduling Pick Slip Generation for instructions.

Picks not included? If you run pick slip generation and the system does not include the picks you were expecting, you can use Pick Print Eligibility (WPPE) to determine the reason why the picks for an order were not included.

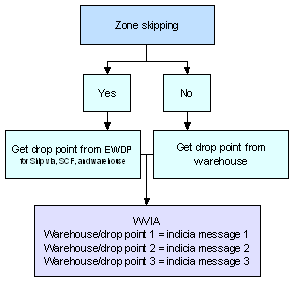

About Zones

The term Zone is used in three specific contexts in pick generation:

- UPS or Parcel Post Shipping zones: These shippers have divided the country into zones, which are used to determine shipping charges. UPS and Parcel Post shipping zones are defined in and validated against the SCF Ship Via table. See Working with SCF/Ship Via Values (WSHV).

- Geographic zones: Geographic zones are regions of the country which relate to weather conditions. Geographic zones are used in zone reservation processing to control shipping dates for weather-sensitive (zone reservation coded) inventory such as plant stock. Geographic zones are defined in and validated against the Geographic Zone table. See Shipping Zone Reservation Overview.

- Warehouse zones: A warehouse zone is the major subdivision within a warehouse. Typically, a warehouse location is identified by zone, aisle, shelf and bin. For example, the location A010203 typically indicates Zone A, Aisle 01, Shelf 02, and Bin 03. Warehouse zone is a criterion for sorting pick slips as they are printed. In addition, you can specify warehouse zones and/or a range of aisles for replenishing your pickable locations. See Creating and Maintaining Locations (WLOC).

For more information: See Preparing Orders for Pick Slip Generation and Performing Pick Slip Generation.

In this topic:

- Work with Streamlined Pick Slip Generation Screen

- Streamlined Pick Slip Generation Screen

- Select Warehouse for Pick Slip Screen

- Select Source Categories for Pick Slip Screen

- Select Shipper for Pick Slip Screen

- Select Pay Type for Pick Slip Screen

- Select Items for Pick Slip Screen

- Select Orders for Pick Slip Screen

- Select Lines of Business for Pick Slip Screen

- Select Location Class for Pick Slip Screen