9 Merchandising

- Setting Up the Item Supporting Tables

- Setting Up the Purchasing Tables

- Creating and Working with Items

- Setting up SKUs

- Working with Sets

- Updating Items and SKUs

- Maintaining Purchase Orders

- Using Purchase Order Inquiry

- Printing Purchase Orders

- Printing Purchase Order Reports

- Performing Inventory Analyses

- Retail Integration (External System to Order Management System)

Setting Up the Item Supporting Tables

Supporting tables: This part describes how to set up the item supporting tables. Generally, these tables contain codes and associated descriptions which you use to define and classify items.

- Working with Hazardous Item Codes (WHAZ) describes creating, changing, deleting, and displaying these codes.

- Working with Item Category Codes (WITG) describes creating, changing, deleting, and displaying these codes.

- Working with Item Classes (WICL) describes creating, changing, deleting, and displaying these codes.

- Working with Item Status (WIST) describes creating, changing, deleting, and displaying these codes.

- Working with Long SKU Classes (WLSC) describes creating, changing, deleting, and displaying these codes.

- Working with Long SKU Departments (WLSD) describes creating, changing, deleting, and displaying these codes.

- Working with Units of Measure (WUOM) describes creating, changing, deleting, and displaying these codes.

- Working with Item Subscriptions (WISB) describes creating, changing, deleting, and displaying subscription items.

- Working with Item Keywords (WKEY) describes creating, changing, and deleting keywords you can use when scanning for an item.

- Working with Item Keyword Exclusions (WEXC) describes creating, changing, and deleting words you can exclude from automatic keyword creation.

- Working with Tax Product Code Cross References (WTPC) describes how to set up a cross reference table to map tax product codes to an item class, long SKU division, long SKU department, and long SKU class combination.

Working with Hazardous Item Codes (WHAZ)

Hazard codes identify hazardous items and indicate if special storage and/or handling is required. You assign a Hazard code to an item in Work with Item/SKUs.

In this topic:

Work with Hazard Codes Screen

How to display this screen: Enter WHAZ in the Fast path field at the top of any menu or select Work with Hazardous Item Codes at a menu.

| Field | Description |

|---|---|

| Code |

A code that identifies the hazard type. Numeric, 2 positions; optional. |

| Description |

The description of the hazard code. Alphanumeric, 40 positions; optional |

| Screen Option | Procedure |

|---|---|

|

Create a new code |

Select Create to advance to the Create Hazard Code Screen. |

|

Change a hazard code |

Select Change for a hazard code to advance to the Change Hazard Code screen. At this screen, you can change any information except the hazard code. See Create Hazard Code Screen for field descriptions. |

|

Delete a hazard code |

Select Delete for a hazard code to delete it. Note: You can delete a code even if it is assigned to an item. The next time you maintain the item, a message similar to the following indicates that the hazard code assigned to the item does not exist:Hazard not found. |

|

Display a hazard code |

Select Display for a hazard code to advance to the Display Hazard Code screen. You cannot change any information on this screen. See Create Hazard Code Screen for field descriptions. |

Create Hazard Code Screen

Purpose: Use this screen to create new hazard codes.

How to display this screen: At the Work with Hazard Codes Screen, select Create.

| Field | Description |

|---|---|

| Code |

A code used to categorize an item as a hazardous material that requires special storage and/or handling. You can assign hazard codes to an item through Work with Item/SKUs. Numeric, 2 positions. Create screen: required. Change screen: display-only. |

| Description |

The hazardous materials description. Alphanumeric, 40 positions; required. |

| Class |

A class of hazardous materials such as flammable or radioactive. These codes are assigned by the Department of Transportation (DOT). The Class field is used for information and reporting only. Alphanumeric, 15 positions; required. |

| Label type |

The type of label that should be produced for this type of hazardous material. The label identifies the hazardous item as flammable or radioactive to warehouse personnel or shippers. The Label type field is used for information and reporting only. The system will not automatically print a label. Alphanumeric, 15 positions; required. |

Working with Item Category Codes (WITG)

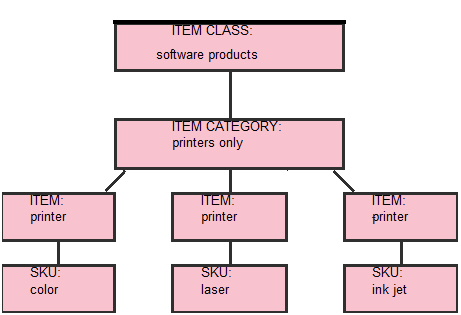

Item category codes classify and group similar items on a level below Item Class. For example, you can assign a group of items within the same item class an Item category of “printers only” to differentiate printers from the other items under that item class.

In this topic:

How Items are Classified and Grouped

Where you can use item category codes:

- Product relationship feature in Order Entry: see Working with Items on the Order.

- Inventory reports, such as the Item Sales Analysis Report, or the Item Stock Status Report

- Applying or excluding promotions; see Working with Promotions (WPRO).

Work with Item Categories Screen

How to display this screen: Enter WITG in the Fast path field at the top of any menu or select Work with Item Categories at a menu.

| Field | Description |

|---|---|

| Category |

A code that identifies the item category. Alphanumeric, 4 positions in alphanumeric order; optional. |

| Description |

The description of the item category. Alphanumeric, 30 positions; optional. |

| Screen Option | Procedure |

|---|---|

|

Create a new code |

Select Create to advance to the Create Item Category Screen. |

|

Change an item category code |

Select Change for an item category code to advance to the Change Item Category screen. At this screen you can change only the description. See Create Item Category Screen for field descriptions. |

|

Delete an item category code |

Select Delete for an item category code to delete it. Note: You can delete a code even if it is assigned to an item. The next time you maintain the item a message such as the following indicates that the code assigned to the item does not exist:Item Category not found. |

|

Display an item category code |

Select Display for an item category code to advance to the Display Item Category screen. You cannot change any information on this screen. See Create Item Category Screen for field descriptions. |

Create Item Category Screen

Purpose: Use this screen to create new item category codes.

How to display this screen: At the Work with Item Categories Screen, select Create.

Instructions:

| Field | Description |

|---|---|

| Cat (Category) |

A code that classifies items that are related to, or compatible with each other. You can assign an Item category to an item in Work with Item/SKUs. Alphanumeric, 4 positions. Create screen: required. Change screen: display-only. |

| Description |

The description of the item category. Alphanumeric, 30 positions; required. |

Working with Item Classes (WICL)

Purpose: Use item class codes to group items for inventory and demand reporting. For example, you can use item class to:

- select which items or SKUs to copy from one offer to another: see Copying SKU Offer Information (MCSO)

- override item offer or SKU offer information: see Working with Offer Overrides by Item Class (WSOI)

- identify a tax exemption for a group of items: see Working with Item Tax Exemptions (WITX)

- grouping items for inventory reporting: see Performing Inventory Analyses)

- design the templates used to present information in specific settings, such as order entry or on a web storefront: see Entering Additional Item Information)

- track demand by customer: see Reviewing Customer History)

- identify when to automatically download availability information to the web storefront: see E-Commerce Interface.

Uploading: You can use the Submit Supporting Data Upload Screen (SDUP) to upload new item class codes. See Importing Item-Related Supporting Data (SDUP) for an overview.

In this topic:

- Work with Item Class Screen

- Create Item Class Screen

- Item Class Restrictions by Customer Class Screen (Working with Restrictions)

- Restrict Item Class by Customer Class (Creating a Restriction)

- Work with Item Restrictions by City Screen (Defining City/State Restrictions)

- Create Item Restriction by City Screen

- Special Handling Restrictions by Item Class Screen

- Restrict Special Handling by Item Class Screen

Work with Item Class Screen

How to display this screen: Enter WICL in the Fast path field at the top of any menu or select Work with Item Class from a menu.

| Field | Description |

|---|---|

| Class |

A code that identifies the item class. Alphanumeric, 3 positions; optional. |

| Description |

The description of the item class. Alphanumeric, 30 positions; optional. |

| Screen Option | Procedure |

|---|---|

|

Create an item class code |

Select Create to advance to the Create Item Class Screen. |

|

Change an item class code |

Select Change for an item class code to advance to the Change Item Class screen. On this screen, you can change any information except the item class. See Create Item Class Screen. |

|

Delete an item class code |

Select Delete for an item class code to delete it. Note: You can delete an item class code even if it is assigned to an item. The next time you maintain the item you will receive a message indicating that the code assigned to the item is not found. |

|

Display an item class code |

Select Display for an item class code to advance to the Display Item Class screen. You cannot change any information on this screen. See Create Item Class Screen for field descriptions. |

|

Define a customer class restriction |

Select Cust Class Restric for an item class code to advance to the Item Class Restrictions by Customer Class Screen (Working with Restrictions). |

|

Define a city restriction |

Select City/State Restrict. for an item class code to advance to the Work with Item Restrictions by City Screen (Defining City/State Restrictions). |

|

Work with special handling restrictions |

Select Special Handling Restrict. for an item class code to advance to the Special Handling Restrictions by Item Class Screen. |

Create Item Class Screen

Purpose: Use this screen to create an item class.

How to display this screen: Select Create at the Work with Item Class Screen.

| Field | Description |

|---|---|

| Item Class |

A code to identify a group of items, such as computer hardware or computer software. Item Class codes are used as a high-level method to sort and classify inventory. You assign an item Class to an item in the Item table. Alphanumeric, 3 positions. Create screen: required. Change screen: display-only. |

| Description |

A description of the item class, such as furniture or computer hardware. The item class description prints on several inventory reports. Alphanumeric, 30 positions; required. |

| Commission % |

Not currently implemented. Numeric, 5 positions with a 2 place decimal; optional. |

| Estimate freight |

Your “best guess” on the vendor's freight charges for items defined in this item class. This unit amount is added to an item's cost to represent the estimated freight charges. Including estimated freight charges is helpful if you sell merchandise before the actual freight charges are known. The system includes estimated freight in the cost of an item when determining gross profit in order entry, maintenance, inquiry and item availability. Gross profit margin is the amount of the item's price that exceeds your cost of the item. You can use gross margin to determine the profit of an item on an order based on the item's selling price, or to determine the profit of an entire order. Determining Gross Profit for more information. Numeric, 7 with a 2-place decimal; optional. |

| Estimated freight % |

Your “best guess” on the vendor's freight charges for items defined in this item class. This percentage amount is added to an item's cost to represent the estimated freight charges. Including estimated freight charges is helpful if you sell merchandise before the actual freight charges are known. The system includes estimated freight in the cost of an item when determining gross profit in order entry, maintenance, inquiry and item availability. Gross profit margin is the amount of the item's price that exceeds your cost of the item. You can use gross margin to determine the profit of an item on an order based on the item's selling price, or to determine the profit of an entire order. See Determining Gross Profit for more information. Numeric, 13 positions with a 2-place decimal; optional. |

| Availability threshold (item class-level) |

Use this field to indicate when to trigger an automatic download of item availability information through the generic inventory API. The system creates a trigger record for an item when its available quantity breeches the threshold, and an integration layer process generates the Inventory Download XML Message (CWInventoryDownload) message to send inventory information to an external system. See Generic Inventory Download API in the Web Services Guide on My Oracle Support (ID 2149144.1) for an overview of message generation rules and processing. Availability threshold hierarchy: The system checks this setting if there is no Avail thrshld (Item-level availability threshold) specified for the individual item. If both the item-level or item class-level thresholds are blank, the system checks the Quantity Available Threshold for Inventory Downloads (G36) system control value. See this system control value for a complete description of how the availability threshold hierarchy works, and for a description of the e-commerce download. Numeric, 5 positions; optional. |

Item Class Restrictions by Customer Class Screen (Working with Restrictions)

Purpose: Item class restriction by customer class is used to prevent the sale of an item to certain customers. For example, if you sell lethal weapons you will need to restrict customers who are under 21 years of age from purchasing them. By creating and using customer class restrictions, you can prevent a class of customers from ordering a class of items. When you define a customer class restriction for an item class, the system:

- displays a message in Order Entry informing you that a particular item is restricted for a certain class of customer

- does not allow you to enter the item on an order for that class of customer

Use this screen to create and delete customer class restrictions.

How to display this screen: At the Work with Item Class Screen, select Customer Class Restriction for an item class.

| Field | Description |

|---|---|

| Item class |

The item class for which you are creating a customer class restriction. Item class code: alphanumeric, 3 positions; display-only. Item class description: alphanumeric, 30 positions; display-only. |

| Customer class |

A code that identifies a class of customers such as for an item restriction, list selection, or reporting purposes. Alphanumeric, 2 positions; optional. |

| Screen Option | Procedure |

|---|---|

|

Create a new restriction by customer class |

Select Create to advance to the Restrict Item Class by Customer Class (Creating a Restriction). |

|

Delete a restriction by customer class |

Select Delete for a customer class restriction to delete it. |

Restrict Item Class by Customer Class (Creating a Restriction)

Purpose: Use this screen to restrict a customer class from ordering a specific item class.

How to display this screen: Select Create at the Item Class Restrictions by Customer Class Screen (Working with Restrictions).

| Field | Description |

|---|---|

| Item class |

The item class code and description for which you wish to create a customer class restriction. Item class code: alphanumeric, 3 positions; display-only. Item class description: alphanumeric, 30 positions; display-only. |

| Customer class |

The customer class code you wish to restrict from a specific item class. Customer Class codes are defined in and validated against the Customer Class table. See Setting Up the Customer Class Table (WCCL). Numeric, 2 positions; required. |

Work with Item Restrictions by City Screen (Defining City/State Restrictions)

Purpose: Item class restrictions by city/state prevent the sale of certain items where it is illegal for them to be sold. For example, it is illegal to sell lethal sprays in Massachusetts. By creating and using City/State restrictions, you can prevent customers in a certain location from ordering a class of items. When you define a city/state restriction for an item class, the system:

- displays a message in Order Entry indicating that the item is restricted for the location

- does not allow you to enter the item on an order for that city/state

How to display this screen: At the Work with Item Class Screen, select City/State Restriction for an item class.

| Field | Description |

|---|---|

| Item class |

The item class code and description for which you are creating a city restriction. Item class: Alphanumeric, 3 positions; display-only. Item class description: Alphanumeric, 30 positions; display-only. |

| City |

The city where an item class restriction applies. Alphanumeric, 25 positions; optional. |

| State |

The two-letter code for the state or province where the city is located. Alphanumeric, 2 positions; optional. |

| Screen Option | Procedure |

|---|---|

|

Create a new restriction by city |

Select Create to advance to the Create Item Restriction by City Screen. |

|

Delete a restriction by city |

Select Delete for a city/state restriction to delete it. |

Create Item Restriction by City Screen

Purpose: Use this screen to restrict a city from a specific item class.

How to display this screen: At the Work with Item Restrictions by City Screen (Defining City/State Restrictions), select Create.

| Field | Description |

|---|---|

| Item class |

The item class code and description for which you are creating a city restriction. Item class code: alphanumeric, 3 positions; display-only. Item class description: alphanumeric, 30 positions; display-only. |

| City |

The city where an item class restriction applies. Alphanumeric, 25 positions; required. |

| State |

The two-letter code for the state or province. State codes are defined in and validated against the State table, which is accessible through the Work with Countries menu option; see Setting Up the Country Table (WCTY). Alphanumeric, 2 positions; required. |

Special Handling Restrictions by Item Class Screen

Purpose: Use this screen to restrict the type of special handling that a customer can order based on item class. For example, you might want to restrict personalizing a t-shirt with an emblem if the process used to attach the emblem damages the t-shirt.

A message similar to the following indicates when you define a special handling code for an item assigned to a restricted item class:

Additional charge code (EM) cannot be used with this item class (RST).

How to display this screen: At the Work with Item Class Screen, select Special Handling Restriction for an item class.

| Field | Description |

|---|---|

| Item class |

The item class code and description that is restricted from special handling. Item class code: alphanumeric, 3 positions; display-only. Item class description: alphanumeric, 30 positions; display-only. |

| S/H code (Special handling code) |

The code for the type of special handling that is restricted. Special handling codes are defined in and validated against Work with Additional Charges (fast path = WADC); see Establishing Additional Charge Codes (WADC). Alphanumeric, 2 positions; optional. |

| Description (Special handling code description) |

The description of the type of special handling that is restricted. Alphanumeric, 30 positions; display-only. |

| Screen Option | Procedure |

|---|---|

|

Delete a special handling restriction |

Select Delete for the special handling restriction to delete it. |

|

Create a special handling restriction |

Select Create to advance to the Restrict Special Handling by Item Class Screen. |

Restrict Special Handling by Item Class Screen

Purpose: Use this screen to restrict special handling codes from being used by an item class.

How to display this screen: On the Special Handling Restrictions by Item Class Screen, select Create.

| Field | Description |

|---|---|

| Item class |

The item class code and description for which you are creating a special handling restriction. Item class code: alphanumeric, 3 positions; display-only. Item class code description: alphanumeric, 30 positions; display-only. |

| S/H code (Special handling code) |

The special handling code you wish to restrict for this item class. Alphanumeric, 2 positions; required. |

Working with Item Status (WIST)

Purpose: Use the Work with Item Status Codes function to define an item status such as obsolete, discontinued, future ship or soldout, which you can then use for:

- selecting items for inventory inquiries and reports

- displaying message lines in Order Entry and Order Maintenance

- assigning a future arrival date

- controlling the display of the item

Assigning to an item: You use the Status field on the first Create Item Screen or Change Item screen to assign a status code to an item. If the item has SKUs, you can also assign a status to the individual SKUs. The SKU status overrides the status of the base item.

Future arrival date: You can default a future ship arrival date to an item in order entry through the Future Orders Item Status (E52) system control value. The date defaults from the Default Future Orders Arrival Date (E53) system control value.

Grouping items: The item status code is one of several types of codes you can use to define and group items. Other codes include department, item class, item category, long SKU class, and long SKU department. See Performing Initial Item Entry (MITM) for information on assigning these codes to items.

Preventing display at the Item Selection screen: The Item Selection screen does not list Items that are assigned to the Item Status for Suppressing Item During Item Selection (L21), provided the status is assigned at the item level rather than the SKU level.

Uploading: You can use the Submit Supporting Data Upload Screen (SDUP) to upload new item status codes. See Importing Item-Related Supporting Data (SDUP) for an overview.

In this topic:

Work with Item Status Screen

How to display this screen: Enter WIST in the Fast Path field at the top of any menu or select Work with Item Status from a menu.

| Field | Description |

|---|---|

| Sts (Status) |

A code that identifies the item status. Alphanumeric, 1 positions; optional. |

| Description |

The description of the item status. Alphanumeric, 30 positions; optional. |

| Screen Option | Procedure |

|---|---|

|

Create a new code |

Select Create to advance to the Create Item Status Screen. |

|

Change an item status code |

Select Change for a code to advance to the Change Item Status screen. At this screen, you can change any information except the code. See Create Item Status Screen for field descriptions. |

|

Delete an item status code |

Select Delete for a code to delete it. Note: You can delete a code even if it is assigned to items. The next time you maintain any items associated with this status code a message will display indicating that the code assigned to the item is not found. |

|

Display an item status code |

Select Display for a code to advance to the Display Item Status Screen. You cannot change any information on this screen. See Create Item Status Screen for field descriptions. |

Create Item Status Screen

To create: At the Work with Item Status Screen, select Create.

| Field | Description |

|---|---|

| Status |

A code that represents an item's status, such as obsolete, discontinued, soldout, etc. You can use item status codes as selection criteria for inventory reporting or to create status message lines to display in Order Entry or Order Maintenance. Alphanumeric, 1 position. Create screen: required. Change screen: display-only. |

| Description |

A description of the item status code. Alphanumeric, 30 positions; required. |

| O/E message 1 and 2 |

The two message lines to display in the Item Status Message Window in Order Entry and Order Maintenance for items with this status code. Alphanumeric, two lines of 50 positions each; optional. |

| Return disposition |

A code that identifies how a returned item assigned to this item status code will be handled by the system, in terms of whether the return updates inventory and the warehouse and location to which the item will be returned. Note: When you return an item that is assigned to an item status code that has a return disposition code defined, the system does not default the return disposition code to the return.Return disposition codes are defined in and validated against the Return Disposition table. Alphanumeric, 2 positions; optional. |

Working with Long SKU Classes (WLSC)

Purpose: Long SKU classes represent class codes for a SKU. For example, you may want to assign a long SKU class code to items that differ from the mail order class codes for the same group of items. These codes are typically used in a retail environment; however, they can be used for other classifications.

Long SKU Class codes are used in conjunction with Long SKU Department codes for reporting purposes. A long SKU class is assigned to an item in the L/S class (Long SKU class) field of the Item table; the system will validate your entry to this field against the Long SKU Class table.

Retail integration (external system to Order Management System): If you are using Retail Integration (external system to Order Management System) by selecting the Use Retail Integration (H26) system control value, you define a retail class within the long SKU department assigned to an item rather than a using a long SKU class. For example, retail class 10 might be Ties within Department 20 (Men’s Apparel), but within Department 30 (Women’s Apparel) class 10 might be Slacks.

As a result, when you are using the Retail Integration (external system to Order Management System), the system validates retail classes against the Retail Class table and denies access to the Work with Long SKU Class menu option. If you attempt to use the menu option, the screen displays an error message: Work with Long SKU Class Not Allowed with SCV H26.

Require long SKU class: If the Require L/S Class (I93) system control value is selected, the system requires you to enter a long SKU class when you create or maintain an item.

Long SKU elements: The entire Long SKU consists of the following elements:

- L/S Style

- L/S Vendor

- L/S Department

- L/S Class

- L/S Color

- L/S Size

- L/S Width

If the Use Retail Integration (H26) system control value is selected, the system requires you to enter a L/S style, L/S subclass, L/S department, and L/S class when you create or maintain an item.

Uploading: If the Use Retail Integration (H26) system control value is unselected, you can use the Submit Supporting Data Upload Screen (SDUP) to upload new long SKU class codes. See Importing Item-Related Supporting Data (SDUP) for an overview.

In this topic:

Work with Long SKU Classes Screen

How to display this screen: Enter WLSC in the Fast Path field at the top of any menu or select Work with Long SKU Classes from any menu.

| Field | Description |

|---|---|

| Class |

A code that represents the long SKU class. Numeric, 4 positions; optional. |

| Description |

The description of the long SKU class. Alphanumeric, 30 positions; optional. |

| Screen Option | Procedure |

|---|---|

|

Create a new long SKU class |

Select Create to advance to the Create Long SKU Class Screen. |

|

Change a long SKU class |

Select Change for a long SKU class to advance to the Change Long SKU Class Screen. At this screen you can change any information except the long SKU class code. See Create Long SKU Class Screen for field descriptions. |

|

Delete a long SKU class |

Select Delete for a long SKU class to delete it. Note: You can delete a code even if it is assigned to an item. The next time you maintain the item you will receive a message indicating that the code assigned to the item is not found. |

|

Display a long SKU class |

Select Display for a long SKU class to advance to the Display Long SKU Class Screen. You cannot change any information on this screen. See Create Long SKU Class Screen for field descriptions. |

Create Long SKU Class Screen

Purpose: Use this screen to create a long SKU class.

How to display this screen: At the Work with Long SKU Classes Screen, select Create.

| Field | Description |

|---|---|

| Class |

A user-defined code that defines the long SKU class. Long SKU Class codes are used in conjunction with Long SKU Department codes for reporting purposes. Numeric, 4 positions. Create screen: required. Change screen: display-only. |

| Description |

The description of the long SKU class code. Alphanumeric, 30 positions; required. |

Working with Long SKU Departments (WLSD)

Purpose: Use the Work with Long SKU Departments menu option to create or work with department codes for a SKU, or if you are using Retail Integration (external system to Order Management System), to assign a retail class code to a long SKU department. For example, you might want to use a long SKU department code that differs from the mail order department codes you assign to a group of items. These codes are typically used in a retail environment; however, they are sometimes used for other classifications.

Long SKU department codes are used in conjunction with long SKU class codes for reporting purposes and to create a hierarchy within a company or entity. If you have the Require Long SKU Division with Long SKU Department (E85) system control value selected, you must specify a long SKU division when creating or maintaining long SKU departments.

Retail integration (external system to Order Management System): If you are using Retail Integration (external system to Order Management System), long SKU class codes are linked to long SKU department codes to create retail classes. See the Work with Retail Class Screen.

A long SKU department is assigned to an item in the L/S dept (Long SKU department) field of the Item table; the system will validate your entry to this field against the Long SKU Department table.

Require long SKU department: If the Require L/S Department (I92) system control value is selected, the system requires you to enter a long SKU department when you create or maintain an item.

Long SKU elements: The entire Long SKU consists of the following elements:

- L/S Style

- L/S Vendor

- L/S Department

- L/S Class

- L/S Color

- L/S Size

- L/S Width

- L/S Subclass

If the Use Retail Integration (H26) system control value is selected, the system requires you to enter a L/S style, L/S subclass, L/S department, and L/S class when you create or maintain an item; also, it is possible to assign a retail class to a long SKU department.

Uploading: Options include:

- Importing Enterprise Foundation Data through Omnichannel Cloud Data Service (OCDS)

- Importing Item-Related Supporting Data (SDUP)

In this topic:

- Work with Long SKU Departments Screen

- Create Long SKU Department Screen

- Work with Retail Class Screen

- Create Retail Class Screen

Work with Long SKU Departments Screen

How to display this screen: Enter WLSD in the Fast Path field at the top of any menu or select Work with Long SKU Department from a menu.

Note:

The Assign Retail Class option is not available if the Use Retail Integration (H26) system control value unselected.| Field | Description |

|---|---|

| Dept. (Department) |

A code that represents the long SKU department. Numeric, 4 positions; optional. |

| Description |

The description of the long SKU department. Alphanumeric, 30 positions; optional. |

| Division |

The division associated with the long SKU department. Not validated by any Order Management System table, but can be used for sorting purposes on reports. Note: The Importing Item-Related Supporting Data (SDUP) and Working with Retail Integration Item Upload (RIIU) options support a maximum of 3 positions for the long SKU division code.Alphanumeric, 4 positions; display-only. |

| Screen Option | Procedure |

|---|---|

|

Create a new long SKU department |

Select Create to advance to the Create Long SKU Department Screen. |

|

Change a long SKU department |

Select Change for a long SKU department to advance to the Change Long SKU Department screen. At this screen, you can change any information except the long SKU department code. See Create Long SKU Department Screen field descriptions. |

|

Delete a long SKU department |

Select Delete for a long SKU department to delete it. Note: You can delete a code even if it is assigned to an item. The next time you maintain the item you will receive a message indicating that the code assigned to the item is not found. |

|

Display a long SKU department |

Select Display for a long SKU department to advance to the Display Long SKU Department Screen. You cannot change any information on this screen. See Create Long SKU Department Screen for field descriptions. |

|

Assign a long SKU department to a retail class |

Select Assign Retail Class for a long SKU department to advance to the Work with Retail Class Screen. This option is available only if you have the Use Retail Integration (H26) system control value selected. |

Create Long SKU Department Screen

Purpose: Use this screen to create a long SKU department.

How to display this screen: Select Create at the Work with Long SKU Departments Screen.

| Field | Description |

|---|---|

| Department |

A user-defined code that identifies a long SKU department. Long SKU department codes are used in conjunction with long SKU class codes for reporting purposes. Numeric, 5 positions. Create screen: required. Change screen: display-only. |

| Description |

The description of the long SKU department code. Alphanumeric, 30 positions; required. |

| L/S division (Long SKU division) |

The code identifying the long SKU division. Long SKU divisions are defined in and validated against the Long SKU Division table. You use the division code to establish a hierarchy and to sort item information when you generate reports. See Creating and Maintaining Long SKU Divisions (WLDV). Required if the Require Long SKU Division with Long SKU Department (E85) system control value is selected. Note: The Importing Item-Related Supporting Data (SDUP) and Working with Retail Integration Item Upload (RIIU) options support a maximum of 3 positions for the long SKU division code.Alphanumeric, 4 positions; required if system control value is selected. |

Work with Retail Class Screen

Purpose: Use this screen to create, change, delete or display a retail class within the long SKU department.

The creation and assignment of retail classes is part of integrating retail operation into Order Management System and is controlled through the Use Retail Integration (H26) system control value. A retail class is a long SKU class that you have assigned to a specific long SKU department. You can create retail classes either through this screen by selecting Create or through a Retail Class File conversion program.

How to display this screen: If the Use Retail Integration (H26) system control value is selected, select Assign Retail Class for a long SKU department at the Work with Long SKU Departments Screen.

| Field | Description |

|---|---|

| L/S Department |

The code and description of the long SKU department to which you will assign a long SKU class. Long SKU departments are linked with long SKU classes in Retail Integration (external system to Order Management System) for creating an organizational hierarchy and for reporting purposes. Department code: Numeric, 4 positions; display-only. Department description: Alphanumeric, 30 positions; display-only. |

| Class |

A code that represents a retail class. A long SKU class that is assigned to a long SKU department is called a retail class. Retail classes are department specific whereas regular long SKU classes are unique and remain constant across departments. For example, Retail Class 10 may be Ties within Department 20 (Men’s Apparel), but within Department 30 (Women’s Apparel) Retail Class 10 may be Slacks. With regular long SKU classes, Class 15 may be Shoes, and will remain Shoes regardless of the department. Retail classes are defined in and validated against the Retail Class table whereas long SKU classes are defined in and validated against the Long SKU Class table. Therefore, when the Use Retail Integration (H26) system control value is selected, you can not access the Work with Long SKU Class menu option or the WLSC fast path. Numeric, 4 positions; optional. |

| Description |

The description of a retail class. If you ran the Retail Class Table conversion program to populate the Retail Class table, the existing long SKU class description defaults for the retail class description. Alphanumeric, 30 positions, optional. |

| Option | Procedure |

|---|---|

|

Create a retail class |

Select Create to advance to the Create Retail Class Screen. |

|

Change a retail class |

Select Change for a retail class to advance to the Maintain Retail Class Screen. At this screen you can change the description for a retail class. If you want to change the retail class code (L/S Class), you must delete (Delete) the existing code and create (Create) a new retail class code. See Create Retail Class Screen for field descriptions. |

|

Delete a retail class |

Select Delete for a retail class to delete it. Note: You can delete a code even if it is assigned to an item. The next time you maintain the item you will receive a message indicating that the code assigned to the item is not found within the long SKU department. |

|

Display a retail class |

Select Display for a retail class to advance to the Display Retail Class Screen. You can not change any information on this screen. See Create Retail Class Screen for field descriptions. |

|

Print a list of retail classes |

Select Print List to print a list of the retail class(es) assigned to the long SKU department. The system submits the job RETAIL_CLS. |

Create Retail Class Screen

Purpose: Use this screen to create a retail class within the particular long SKU department.

How to display this screen: Select Create at the Work with Retail Class Screen.

| Field | Description |

|---|---|

| L/S Department |

The code and description of the long SKU department to which you will assign a long SKU class. Long SKU departments are used with long SKU classes in Retail Integration (external system to Order Management System) to create an organizational hierarchy and for reporting purposes. Department code: Numeric, 4 positions; display-only. Department description: Alphanumeric, 30 positions; display-only. |

|

L/S Class (Long SKU Class) |

A code that represents a retail class. A long SKU class that is assigned to a long SKU department is called a retail class. Retail classes are department-specific, while regular long SKU classes are unique and remain constant across departments. For example, Retail Class 10 might be Ties within Department 20 (Men’s Apparel), but within Department 30 (Women’s Apparel) Retail Class 10 might be Slacks. With regular long SKU classes, Class 15 might be Shoes, and remain Shoes regardless of the department. Retail classes are defined in and validated against the Retail Class table, while long SKU classes are defined in and validated against the Long SKU Class table. As a result, when the Use Retail Integration (H26) system control value is selected, you can not access the Work with Long SKU Class menu option. Numeric, 4 positions; required. |

| Retail Class Description |

The description of a retail class. If you ran the Retail Class Table conversion program to populate the Retail Class table, the existing long SKU class description defaults for the retail class description. Alphanumeric, 30 positions, required. |

Completing this screen: Enter the L/S Class (Retail Class) code and Retail Class Description and select OK. The system clears the fields and indicates: Retail Class (xxx) created.

Working with Units of Measure (WUOM)

Purpose: Use this option to defines the standard units of measure by which items are purchased and sold. Typical units of measure include cases, pounds, dozens, and “eaches.” You define a unit of measure for each item in the Item and Vendor Item tables.

After setting up units of measure, use Working with Unit of Measure Conversions (WUMC) to set up conversions so that units and costs calculate correctly in PO Maintenance and PO Receipts.

In this topic:

Work with Units of Measure Screen

How to display this screen: Enter WUOM in the Fast Path field in the top of any menu or select this option from a menu.

| Field | Description |

|---|---|

| UOM (Unit of measure) |

A code that represents the unit of measure. Alphanumeric, 3 positions; optional. |

| Description |

The description of the unit of measure. Alphanumeric, 30 positions; optional. |

| Units |

The number of units (single items) represented by this unit of measure, such as 12 units in a case. Numeric, 4 positions; optional. |

| Screen Option | Procedure |

|---|---|

|

Create a new unit of measure |

Select Create to advance to the Create Unit of Measure Screen. |

|

Change a unit of measure |

Select Change for a unit of measure to advance to the Change Unit of Measure screen. At this screen you can change any information except the unit of measure. See Create Unit of Measure Screen for field descriptions. |

|

Delete a unit of measure |

Select Delete for a unit of measure to delete it. Note: You can delete a unit of measure even if it is assigned to an item. The next time you maintain the item you will receive a message indicating that the unit of measure assigned to the item is not found. |

|

Display a unit of measure |

Select Display for a unit of measure to advance to the Display Unit of Measure Screen. You cannot change any information on this screen. See Create Unit of Measure Screen for field descriptions. |

Create Unit of Measure Screen

To create: At the Work with Units of Measure Screen, select Create.

You must create units of measure before working with unit of measure conversions. See Working with Unit of Measure Conversions (WUMC).

| Field | Description |

|---|---|

| Unit of measure |

A code that represents a unit of measure for an item. Typical units of measure include: EA - each IN - inches C12 - case of 12 Alphanumeric, 3 positions. Create screen: required. Change screen: display-only. |

| Description |

A description of the vendor unit of measure such as each, 12 cases, or inches. Alphanumeric, 30 positions; required. |

| Units |

The number of units (single items) represented by this unit of measure, such as 12 units in a case. Numeric, 4 positions; optional. |

Working with Item Subscriptions (WISB)

Purpose: Use the Item Subscriptions function to define the particulars of a subscription item you sell to your customers. You must define a record in this table for each subscription item you create.

Overview: Defining and selling subscriptions through Order Management System involves the following process:

- Define the subscription in the Item table. Select the Subscription field and the Non/inv (non-inventory item) field. See Performing Initial Item Entry (MITM).

- Define the subscription in the Item Subscription table.

- Enter orders and pick slips. You enter a subscription on an order as you do other items. When you accept the order, the system creates a separate pre-generated pick for the subscription item. When you generate pick slips for the order, the system bills the subscription item immediately and indicates on the pick slip that the subscription is shipping separately. See Preparing Orders for Pick Slip Generation and Performing Pick Slip Generation for more information on preparing and generating picks.

- Generate the Subscription Extract file. See Generating the Subscription Extract Table (WGSE) for information on creating a file of customers to receive subscription items.

- Purge the Subscription Extract file. Periodically, you can use the purge function to clear the file of closed or canceled subscriptions. You can also clear the file completely. See Generating the Subscription Extract Table (WGSE) for more information on purging subscription records or clearing the file.

You can also review, cancel, or change a specific customer's subscription information through the Work with Customers function and in standard Order Inquiry. See Displaying More Options in OIOM.

In this topic:

Work with Item Subscriptions Screen

How to display this screen: Enter WISB in the Fast path field at the top of any menu or select this option from a menu.

| Field | Description |

|---|---|

| Item |

The item code that identifies the subscription. An item is designated as a subscription by a selected Subscription field of the Item (Base Information) record. Items are defined in and validated against the Item table. Alphanumeric, 12 positions. |

| Cur iss (Current issue number) |

The number of the subscription that will be the first issue sent when the customer orders the subscription or the issue presently being mailed. Numeric, 3 positions. |

| # of int (Number of intervals) |

The number of issues the customer should receive when purchasing the subscription. Numeric, 3 positions. |

| # of Days |

The number of days between each issue. Numeric, 3 positions. |

| Orig item (Original item) |

The original subscription item number associated with this subscription. This is used when a subscription item is offered with different intervals (such as a subscription with a multi-period offering). This is used so that the customer can extend the length of a subscription. Example: The customer purchased a year's subscription (item SUBSCR#1). Near the end of the subscription period, the customer calls back and orders another year's subscription (item SUBSCR#2). The system:

|

|

Items are defined in and validated against the Item table. Note: The system validates that the item number entered is a subscription item (Subscription = Selected and Non/inv = Selected for the item).Alphanumeric, 12 positions. |

| Screen Option | Procedure |

|---|---|

|

Create a new item subscription |

Select Create to display the Create Item Subscription Screen. |

|

Change an item subscription |

Select Change for an item subscription to advance to the Change Item Subscription Screen. At this screen you can change any information except the subscription item code and description. See Create Item Subscription Screen for field descriptions. Note: Changing subscription information does not change existing subscriptions; however, new subscriptions will reflect these changes. |

|

Delete an item subscription |

Select Delete for an item subscription to delete it. Note: The system does not allow you to delete an item subscription if there are open subscriptions for the item. The system issues the following message if you attempt to delete an active subscription:Open subscriptions exist for this item -- cannot delete |

|

Display an item subscription |

Select Display for an item subscription to advance to the Display Item Subscription Screen. You cannot change any information on this screen. See Create Item Subscription Screen for field descriptions. |

Create Item Subscription Screen

To create: At the Work with Item Subscriptions Screen, select Create.

Note:

You must create an Item Subscription for each subscription item you create in the Item table.| Field | Description |

|---|---|

| Item/SKU |

The item code (optionally, the SKU) that identifies the subscription item. You designate an item as a subscription by selecting the Subscription and Non/inv fields of the Item table; see Performing Initial Item Entry (MITM). The description of the item appears below the item/SKU at the Change Item Description screen, and is display-only. Item code: Alphanumeric, 12 positions. SKU: Three 4-position fields. Create screen: required. Change screen: display-only. |

| Current issue# (Current issue number) |

The number of the subscription that will be the first issue sent when the customer orders the subscription or the number of the issue presently being mailed. Numeric, 3 positions; required. |

| Issue description |

The description associated with the current issue of the subscription item. Alphanumeric, 25 positions; required. |

| # of intervals |

The number of issues the customer should receive when purchasing the subscription item. Numeric, 3 positions; required. |

| Interval days |

The number of days between each issue. Numeric, 3 positions; optional. |

| Original item/SKU |

The original subscription item code associated with this subscription, if any. See the field description above for more information. Item code: alphanumeric, 12 positions; required. SKU: three 4-position fields; required. |

Working with Item Keywords (WKEY)

Purpose: Use item keywords as a way to identify and scan for items other than by item number and item description. For example, if you sell books and the item number is a code, AN8975H, and the description is the title of the book, "The Outer Ring," you may want to use the author's name as a keyword: "Newbold." This way you can scan for items (books) that have been written by the author, instead of scanning for a specific item (by item code or the title of a specific book).

You can create as many keywords for an item as you want. For example, if you sell books and create the author's name as a keyword for each book, you could further define the item by creating a keyword for the type of book it is, for example, “Science Fiction.”

Web storefront: Keywords are included in the information you can download to the web storefront to make customers’ item searches easier. See Downloading E-Commerce Offer Files (EOFR).

Retail integration (external system to Order Management System) item upload: If the Auto-Generate Item Keywords from Description (F79) system control value is selected, the system automatically creates keywords for items created or updated through the RI Item Upload process for record type 01 Item/SKU; see Working with Retail Integration Item Upload (RIIU).

Note:

You can create item keywords only at the item level, not at the SKU level.In this topic:

- Generating Keywords During Item Entry

- First Work with Keywords for Item Screen

- Second Work with Keywords for Item Screen (ADD Mode)

- Work with Item Keywords Screen (WKEY)

- Create Item Keyword Screen

- Keyword Selection Screen (Scanning for Items Using Item Keywords)

For more information: See Working with Item Keyword Exclusions (WEXC).

Generating Keywords During Item Entry

Keyword creation/automatic advancement: There are two system control values that control automatic keyword creation and screen advancement at item entry:

| SCV setting Create Keywords at Item Entry (F78) | Auto-Generate Item Keywords from Description (F79) SCV setting | Result when you create a new item |

|---|---|---|

|

Selected |

Selected |

You advance to the First Work with Keywords for Item Screen. The system generates a keyword for each word in the item description. |

|

Selected |

Unselected |

You advance to the Second Work with Keywords for Item Screen (ADD Mode). The system has not created any keywords. |

|

Unselected |

Selected |

You do not advance automatically to either of the Work with Keywords screens; however, the system generates a keyword for each word in the item description. |

|

Unselected |

Unselected |

You do not advance automatically to either of the Work with Keywords screens, and the system does not generate keywords. |

Note:

If system control value Create Keywords at Item Entry (F78) is selected, you first advance to the Create Vendor Item screen when you create an item; then, when you complete the Create Vendor Item screen, to the Work with Keywords for Item screen.First Work with Keywords for Item Screen

Purpose:

- During item entry: Use this screen to review the keywords the system has created automatically, if any, and to delete or create keywords.

- To work with keywords: You can also use this screen at any time to review or delete existing keywords for an item, or create new keywords.

About item keywords: see Working with Item Keywords (WKEY) for an overview, and Keyword Selection Screen (Scanning for Items Using Item Keywords) for sample keyword selection when scanning for an item.

How to display this screen:

- depending on system control value settings, select OK on the Create Item (Base Information) screen in Work with Item/SKUs, or on the Create Vendor Item screen; see Generating Keywords During Item Entry

- select Keywords for an item at a Work with Items Screen

- select Create at the Second Work with Keywords for Item Screen (ADD Mode)

| Field | Description |

|---|---|

| Item |

The code and description for the item you are creating or working with. Item code: alphanumeric, 12 positions; display-only. Item description: alphanumeric, 120 positions; display-only. |

| Keyword |

A word to further define an item. Item keywords are used to scan for a specific item based on information that is not found in the item code or item description. During item entry: Depending on your system control value settings, the system may automatically create a keyword using each word in the item description (see Generating Keywords During Item Entry). You can delete any unneeded keyword at this screen by selecting Delete for it. Alphanumeric, 20 positions; optional. |

| Screen Option | Procedure |

|---|---|

|

Delete an item keyword |

Select Delete for a keyword to delete it. |

|

Add item keywords |

Select Create to switch to the Second Work with Keywords for Item Screen (ADD Mode). |

Second Work with Keywords for Item Screen (ADD Mode)

Purpose: Use this screen to create item keywords.

About item keywords: see Working with Item Keywords (WKEY) for an overview, and Keyword Selection Screen (Scanning for Items Using Item Keywords) for sample keyword selection when scanning for an item.

How to display this screen:

- depending on system control value settings, select OK on the Create Item (Base Information) screen in Work with Item/SKUs; see Generating Keywords During Item Entry

- select Create at the First Work with Keywords for Item Screen

| Field | Description |

|---|---|

| Item code |

A user-defined code that represents a unit of inventory. Item codes are validated against the Item table. The item description appears to the right. Alphanumeric, 15 positions; display-only. |

| Keyword |

A word to further define an item. Item keywords are used to scan for a specific item based on information other than the item code or item description. Alphanumeric, 20 positions; required. |

| Screen Option | Procedure |

|---|---|

|

Create item keywords |

Use each enterable line to enter a separate item keyword. |

|

Review existing item keywords |

Select Display to advance to the First Work with Keywords for Item Screen. |

Work with Item Keywords Screen (WKEY)

Purpose: Use this screen to create, delete and review item keywords.

About item keywords: see Working with Item Keywords (WKEY) for an overview, and Keyword Selection Screen (Scanning for Items Using Item Keywords) for sample keyword selection when scanning for an item.

How to display this screen:

- enter WKEY in the Fast path field at the top of any menu or select this option from a menu, or

- select Item Keywords on the Item Support Maintenance pop-up window in Work with Item/SKUs

| Field | Description |

|---|---|

| Keyword |

A word to further define an item. Item keywords are used to scan for a specific item based on information other than the item code or item description. Alphanumeric, 20 positions; optional. |

| Item |

A user-defined code that represents a unit of inventory. Item codes are validated against the Item table. Alphanumeric, 15 positions; optional. |

| Description |

The description of the item. Alphanumeric, 120 positions; display-only. |

| Screen Option | Procedure |

|---|---|

|

Delete an item keyword |

Select Delete for the item keyword you wish to delete. |

|

Create an item keyword |

Select Create to advance to the Create Item Keyword Screen. |

Create Item Keyword Screen

Purpose: Use this screen to create a keyword for an item.

How to display this screen: Select Create on the Work with Item Keywords Screen (WKEY).

| Field | Description |

|---|---|

| Item |

A user-defined code that represents a unit of inventory. Item codes are validated against the Item table. Alphanumeric, 15 positions; required. |

| Keyword |

A word to further define an item. Item keywords are used to scan for a specific item based on information other than the item code or item description. Alphanumeric, 20 positions; required. |

Keyword Selection Screen (Scanning for Items Using Item Keywords)

Purpose: Use this screen to scan for an item by keyword and to then select the item. You would scan for an item by keyword if you did not know the item code or item description.

Example: You sell books. An item code is TB7528J, the item description is the title of the book, “Collective Thoughts.” You do not know the item code or item description, only that the author of the book is Thomas Briggs and the book is a collection of his poems. You could scan for the item in order entry or order maintenance by the keyword BRIGGS or the keyword POETRY.

How to display this screen: On the Item Selection screen, selecting Scan by Keyword. You can advance to the Item Selection screen by clicking on an Item scan field. You also advance to this screen in order entry by prompting on the Item field if the Auto-Generate Item Keywords from Description (F79) system control value is selected.

| Field | Description |

|---|---|

| Keyword |

A word to further define an item. Item keywords are used to scan for a specific item using information other than the item code or item description. Alphanumeric, 20 positions; optional. |

| Item |

A user-defined code that represents a unit of inventory. Item codes are validated against the Item table. Alphanumeric, 15 positions; optional. |

| Description |

The description of the item. Alphanumeric, 120 positions; display-only. |

| Screen Option | Procedure |

|---|---|

|

Select an item |

Select an item keyword to select the item. |

|

Switch to the Item Selection screen |

Select Scan by Description. |

Working with Item Keyword Exclusions (WEXC)

Purpose: Use Work with Keyword Exclusions to exclude certain words in the item description from being created as item keywords, if these words would not be useful for keyword scanning.

About item keywords: You can use item keywords as a way to identify and scan for an item other than by item number. For example, if you sell books and the item number is a code, AN8975H, and the description is the title of the book, “The Outer Ring,” you may want to use the author's name as a keyword: “Newbold.” This way you can scan for items (books) that have been written by the author, instead of scanning for a specific item (by item code or the title of a specific book).

When to use exclusions? The system automatically creates item keywords based on the words from the item's description if the Auto-Generate Item Keywords from Description (F79) system control value is selected. You might want to exclude words such as “the,” “with,” and “on” from being created as keywords; although these words might be part of an item descriptions, they would not be useful for scanning.

Related topic: See Working with Item Keywords (WKEY), for more information on creating item keywords and scanning for an item using item keywords.

In this topic:

First Work with Keyword Exclusions Screen

How to display this screen: Enter WEXC in the Fast path field at the top of any menu or select Work with Keyword Exclusions from a menu.

| Field | Description |

|---|---|

| Exclusion |

A word that has been excluded from automatically generating a keyword from the item's description when you create an item. The system automatically generates item keywords from the item's description when you create an item if the Auto-Generate Item Keywords from Description (F79) system control value is selected. Alphanumeric, 20 positions; optional. |

| Screen Option | Procedure |

|---|---|

|

Delete a keyword exclusion |

Select Delete for a keyword exclusion to delete it. |

|

Create keyword exclusions |

Select Create to advance to the Second Work with Keyword Exclusions Screen. |

Second Work with Keyword Exclusions Screen

Purpose: Use this screen to create keyword exclusions.

How to display this screen: Select Create on the First Work with Keyword Exclusions Screen.

| Field | Description |

|---|---|

| Exclusion |

A word that has been excluded from automatically generating a keyword from the item's description when you create an item. The system automatically generates item keywords from the item's description when you create an item if the Auto-Generate Item Keywords from Description (F79) system control value is selected. The system displays 17 exclusion fields where you can enter words to exclude when creating keywords automatically. Alphanumeric, 20 positions; optional. |

| Screen Option | Procedure |

|---|---|

|

Create keyword exclusions |

Use each enterable line to enter a separate keyword exclusion. |

|

Display keyword exclusions |

Select Display to advance to the First Work with Keyword Exclusions Screen |

Working with Tax Product Code Cross References (WTPC)

Purpose: Use this menu option to create a cross reference between a tax product code and an item class, long SKU division, long SKU department, and long SKU class combination.

Avalara Tax Integration: The Avalara AvaTax integration uses the tax product code to determine the tax for a particular product class. If a tax code is not associated with an item, AvaTax assigns a default tax code of U0000000, indicating an unknown tax code. See the Avalara AvaTax Interface and Avalara AvaTax Setup for more information.

Determining a match: In order to be considered a match to a tax product code, the item class, long SKU division, long SKU department, and long SKU class combination values must exactly match the values defined for an item.

Example: The following tax product code cross references are defined.

| Item Class | L/S Division | L/S Department | L/S Class | Tax Product Code |

|---|---|---|---|---|

|

NA |

NA |

100 |

100 |

PG068810 |

|

NA |

100 |

100 |

NA |

PC040111 |

|

ACC |

NA |

NA |

NA |

PA028802 |

|

ACC |

100 |

100 |

NA |

NA |

|

ACC |

100 |

100 |

100 |

98922 |

The system assigns the tax product code to each item using the item class, long SKU division, long SKU department, and long SKU class combination to find an exact match to a tax product code cross reference.

| Item | Item Class | L/S Division | L/S Dept | L/S Class | Results |

|---|---|---|---|---|---|

|

A101 |

ACC |

100 |

100 |

200 |

no match found |

|

A202 |

ACC |

NA |

100 |

200 |

no match found |

|

A303 |

100 |

100 |

100 |

no match found |

|

|

A404 |

ACC |

NA |

NA |

NA |

match to tax product code PA028802 |

|

A505 |

NA |

NA |

100 |

100 |

match to tax product code PG068810 |

In this topic:

Work with Tax Product Code Cross Reference Screen

Purpose: Use this screen to work with tax product code cross references.

How to display this screen: Enter WTPC in the Fast path field at the top of any menu or select Work with Tax Product Code Cross Reference from a menu.

| Field | Description |

|---|---|

| Item Class |

A code to identify a group of items, such as computer hardware or computer software. Item Class codes are used as a high-level method to sort and classify inventory. You assign an item class to an item in the Item table (MITM). Enter a valid item class code and select OK to display tax product code cross references that match your entry. Alphanumeric, 3 positions; optional. |

| L/S Division |

A code that represents a long SKU division. L/S divisions are used in conjunction with long SKU departments and long SKU classes for reporting purposes and to create a hierarchy within a company or entity. Long SKU division codes are defined in and validated against the L/S Division table (WLDV). Enter a valid long SKU division code and select OK to display tax product code cross references that match your entry. Alphanumeric, 4 positions; optional. |

| L/S Department |

A code that represents a long SKU department. L/S departments are used in conjunction with long SKU divisions and long SKU classes for reporting purposes and to create a hierarchy within a company or entity. Long SKU department codes are defined in and validated against the L/S Department table (WLSD). Enter a valid long SKU department code and select OK to display tax product code cross references that match your entry. Alphanumeric, 5 positions; optional. |

| L/S Class |

A code that represents a long SKU class. L/S classes are used in conjunction with long SKU departments and long SKU divisions for reporting purposes and to create a hierarchy within a company or entity. Long SKU class codes are defined in and validated against the L/S Class table (WLSC). Enter a valid long SKU class code and select OK to display tax product code cross references that match your entry. Alphanumeric, 4 positions; optional. |

| Tax Product Code |

A code used to determine the tax for a particular item. Enter a valid tax product code and select OK to display tax product code cross references that match your entry. Alphanumeric, 24 positions; optional. |

| Screen Option | Procedure |

|---|---|

|

Create a tax product code cross reference |

Select Create to advance to the Create Tax Product Code Cross Reference Screen. |

|

Change a tax product code cross reference |

In the Action column, select Change for a tax product code cross reference to advance to the Change Tax Product Code Cross Reference screen. At this screen, you can change the Tax Product Code. See Create Tax Product Code Cross Reference Screen for field descriptions. |

|

Delete a tax product code cross reference |

In the Action column, select Delete for a tax product code cross reference to delete it. |

Create Tax Product Code Cross Reference Screen

Purpose: Use this screen to create a cross reference between a tax product code and an item class, long SKU division, long SKU department, and long SKU class combination.

How to display this screen: Select Create on the Work with Tax Product Code Cross Reference Screen.

| Field | Description |

|---|---|

| Item Class |

A code to identify a group of items, such as computer hardware or computer software. Item Class codes are used as a high-level method to sort and classify inventory. You assign an item class to an item in the Item table (MITM). Item class codes are defined in and validated against the Item Class table; see Working with Item Classes (WICL). Alphanumeric, 3 positions. Create screen: optional. Change screen: display-only. |

| L/S Division |

A code that represents a long SKU division. L/S divisions are used in conjunction with long SKU departments and long SKU classes for reporting purposes and to create a hierarchy within a company or entity. Long SKU division codes are defined in and validated against the L/S Division table; see Creating and Maintaining Long SKU Divisions (WLDV). Alphanumeric, 4 positions. Create screen: optional. Change screen: display-only. |

| L/S Department |

A code that represents a long SKU department. L/S departments are used in conjunction with long SKU divisions and long SKU classes for reporting purposes and to create a hierarchy within a company or entity. Long SKU department codes are defined in and validated against the L/S Department table; see Working with Long SKU Departments (WLSD). Alphanumeric, 5 positions. Create screen: optional. Change screen: display-only. |

| L/S Class |

A code that represents a long SKU class. L/S classes are used in conjunction with long SKU departments and long SKU divisions for reporting purposes and to create a hierarchy within a company or entity. Long SKU class codes are defined in and validated against the L/S Class table; see Working with Long SKU Classes (WLSC). Alphanumeric, 4 positions. Create screen: optional. Change screen: display-only. |

| Tax Product Code |

A code used to determine the tax for a particular item. If you use the AvaTax interface, this is a tax code defined in AvaTax. Alphanumeric, 24 positions; required. |

Setting Up the Purchasing Tables

Purpose:

- Working with Buyers (WBUY) explains how to create, change, delete, and display buyer information.

- Working with Purchase Order Ship Via (WPSV) explains how to create, change, delete, and display ship via codes for purchase orders.

- Working with Vendors (WVEN) includes how to create, change, delete, and display vendor information.

- Working With PO Additional Charges (WPAC) explains how to create, change, delete, and display additional charges for purchase orders.

- Working with Unit of Measure Conversions (WUMC) explains how to create, change, delete, and display unit of measure conversions between your selling unit of measure and the vendor's unit of measure.

- Working with Vendor Items (WVNI) describes how to create, change, delete, and display vendor item information. Vendor items are a reference between the vendor's item information and the item information used by your company.

- Working with Vendor Upload (LVUP) explains how to upload vendor information into Order Management System.

- Working with Vendor Upload (LVUP) explains how to upload vendor information into Order Management System.

Working with Buyers (WBUY)

Buyers are eligible to create purchase orders and may be assigned to purchase specific items. A record must be established on the system for every buyer. The Buyer table is required in order to use the Purchase Order function.

In this topic:

Work with Buyers Screen

Purpose: Use this screen to create, change, delete, or display buyer information. Buyers are eligible to create purchase orders and may be assigned to purchase specific items. A record must be established on the system for every buyer.

How to display this screen: Enter WBUY in the Fast Path field at the top of any menu or select Work with Buyers from a menu.

| Field | Description |

|---|---|

| Buyer |

A code to identify a buyer. This code could be the Buyer's initials or any other coding system to identify the buyers. Alphanumeric, 3 positions; optional. |

| Description |

The buyer's name, which is used on selected reports where the Buyer is included. Alphanumeric, 30 positions; optional. |

| Screen Option | Procedure |

|---|---|

|

Create a new buyer |

Select Create to advance to the Create Buyer Screen. |

|

Change buyer information |

Select Change for a buyer to advance to the Change Buyer Screen. At this screen you can change any information except the buyer. See Create Buyer Screen for field descriptions. |

|

Delete buyer information |

Select Delete for a buyer to delete it. |

|

Display buyer information |

Select Display for a buyer to advance to the Display Buyer Screen. You cannot update any information on this screen. See Create Buyer Screen for field descriptions. |

Create Buyer Screen

To create: At the Work with Buyers Screen, select Create.

| Field | Description |

|---|---|

| Buyer |

The code that identifies a buyer on the system. A buyer is someone who creates the purchase order for an item. A Buyer manages inventory purchases which could be both initial and rebuy purchases or just rebuys. This code could represent the Buyer's initials or any other coding system to identify the Buyer. Alphanumeric, 3 positions. Create screen: required. Change screen: display-only. |

| Description |

The buyer's name, which is used on selected reports where the Buyer is included. Alphanumeric, 30 positions; required. |

Working with Purchase Order Ship Via (WPSV)

Purpose: Use the Purchase Order Ship Via function to add or maintain purchase order ship via codes. The system uses purchase order ship via codes during Purchase Order Maintenance to designate your preferred shipping method for the inventory. The system prints ship via information on the purchase orders.

In this topic:

- Drop Ship Purchase Order Setup for Purchase Order Ship Vias

- Work with Purchase Order Ship Via Screen

- Create Purchase Order Ship Via Screen

Drop Ship Purchase Order Setup for Purchase Order Ship Vias

Overview: When you generate drop ship purchase orders, the system defaults the ship via code from the order, as set up through Working with Ship Via Codes (WVIA), onto the header of the drop ship purchase order, even though the Ship via field on the purchase order header is validated against the Purchase Order Ship Via table rather than the regular (order) Ship Via table.

The description of the purchase order ship via prints on the standard purchase order. As a result, if you generate drop ship purchase orders and use the standard purchase order print programs, you will need to set up purchase order ship via codes that match the regular (order) ship vias, so that the ship via is identified correctly to your drop ship vendors.

Example: A customer places an order for drop ship item DS123, and the ship via on the order is 10: UPS two-day. When you run Selecting Vendors for Drop Ship Processing (MDSP), it generates a drop ship purchase order to the vendor for the item, and sets the purchase order ship via for the generated drop ship purchase order to 10. When you print the drop ship purchase order using the standard purchase order print programs, the description of the purchase order ship via 10, set up through Working with Purchase Order Ship Via (WPSV), prints. In order to indicate the correct ship via to your vendor, the description of regular (order) ship via 10 and purchase order ship via 10 should be the same.

Specifying purchase order print programs: You use the PO Print Program (C64) and PO Print Program for PO Print in PO Sequence (C76) system control values to specify the regular and drop ship purchase order print program(s). Standard setting for both values are PURCHORDG (graphical format). See the Purchase Order for samples and field descriptions.