11 System Operations

Operating Background Jobs

Topics in this part: The following topics describe the functions available to operate the background ASYNC jobs.

-

Using the ASYNC Jobs (MBJC) describes the purpose of the background jobs, provides a brief overview of the each background ASYNC job, explains the steps to use to start and end the background ASYNC jobs, and shows you how to location the function.

-

Working with the CNTL_ASYNC Job shows you how to start and end the background ASYNC jobs, how to reorganize the data queues associated with the background ASYNC jobs, and how to change the status of the background ASYNC jobs.

-

Working with the BILL_ASYNC Job shows you how to display the Billing Header Data Queue, how to correct Billing ASYNC errors, how to change the status of the Billing ASYNC job, and describes the table updates that occur when records are processed by the BILL_ASYNC job.

-

Working with the EBO_ASYNC Job shows you how to display the Evaluate B/O Data Queue, how to correct EBO_ASYNC errors, how to change the status of the EBO_ASYNC job, and describes the table updates that occur when records are processed by the EBO_ASYNC job.

-

Working with the ORDR_ASYNC Job shows you how to display the Order Ship To Data Queue, how to correct ORDR_ASYNC errors, how to change the status of the ORDR_ASYNC job, and describes the table updates that occur when records are processed by the ORDR_ASYNC job.

-

Working with the OTHR_ASYNC Job shows you how to display the PO Header Data Queue, how to correct OTHR_ASYNC errors, how to change the status of the OTHR_ASYNC job, and describes the table updates that occur when records are processed by the OTHR_ASYNC job.

-

Purging Active Procedures (MACP)shows you how to display the Active Procedures for a user and how to delete stranded Active Procedure records for a user.

-

Working with Integration Layer Processes (IJCT) shows you how to work with the integration layer processes used for transmitting data between Order Management System and an external system.

Background Job Control (MBJC)

| For information on: | See: |

|---|---|

|

how to use the ASYNC (asynchronous) jobs, which process updates to tables related to transaction activity |

|

|

working with the CNTRL_ASYNC job reorganizing the queues |

Working with the CNTL_ASYNC Job |

|

the BILL_ASYNC job, which processes updates related to shipments and returns |

|

|

the EBO_ASYNC job, which processes updates related to changes in backordered items |

|

|

the ORDR_ASYNC job, which processes updates related to order entry and maintenance |

|

|

the OTHR_ASYNC job, which processes updates related to purchase order activity |

Purging Active Procedures (MACP)

Purpose: Use the Purge Active Procedures function to delete a user procedure that remains in an active status when the user is no longer in the application.

For example, if a terminal crashes when an operator is entering orders, the Active Procedures record for the user may not be deleted from the table. If a record exists in the Active Procedures table, the system thinks that the person is still using the application because the function was not exited properly.

If there are stranded Active Procedures records for any of the following functions, they must be deleted, otherwise the background ASYNC jobs cannot be ended:

-

Order Entry/Maintenance

-

Purchase Order Maintenance

-

Receiving

-

Confirmation

-

PC Manifest or the Generic Pick In API (Shipments, Voids, and Backorders)

For more information see the Web Services Guide on My Oracle Support (ID 2149144.1).

When the ASYNC jobs are ended, the system checks the Active Procedures table to see if there are any active records for these applications. A pop-up window indicates the User ID and application that is still active. You should ask that the user exit the application. If the user is not in the application, delete the record from the Active Procedures table.

Note:

This function should not be used to delete Active Procedures records for users who are still using an application. If you delete Active Procedures records while a user is still in the application, the user job will not be ended; that user can still enter transactions in the application, but transaction records cannot be sent to the data queues for processing because the data queues are reorganized when the ASYNC jobs end. No back end table updates for that user's transactions will be posted, which will cause your data tables to be out of sync.Scheduling the active procedure purge: You can schedule the active procedure purge for the functions listed above using the PFR0121 Delete Stranded Active Procedures periodic function. The system deletes all active procedures for interactive jobs that are older than the number of hours defined in the periodic function’s Parameter field. If the Parameter field is blank, the default number of hours is 24.

Interrupting confirmation email generation: You can delete the active procedure related to generation of shipment and return confirmations (Type = SC) in order to interrupt the generation process. The system keeps track of the last email generated so that you can restart the generation process at a later time. See Stopping and Restarting Shipment and Return Confirmation Emails for an overview.

To see active procedures for all users in your environment: Use the Purge Active Procedures Across Users (MACX) menu option to display active procedures for all users and to purge selected procedures as needed.

In this topic:

-

Purge Active Procedures Screen (Selecting the User to Purge)

-

Purge User’s Active Procedures (Deleting an Active Procedure)

For more information: See Purge Active Procedures Across Users (MACX).

Purge Active Procedures Screen (Selecting the User to Purge)

Purpose: Use this screen to enter the User ID of the person whose record must be deleted from the Active Procedures table.

How to display this screen: Enter the Active Procedures Purge fast path name, MACP in the Fast path field at the top of any menu.

| Field | Description |

|---|---|

|

User |

The User ID of the person whose active procedure is being deleted. The User ID is validated against the User Profile table. Alphanumeric, 10 positions; required. |

Purge User’s Active Procedures (Deleting an Active Procedure)

Purpose: This screen displays the system procedures that are currently active for the selected user.

Note:

Important: Be sure that the user has exited the application before you delete an Active Procedures record. When you a delete a record, the system no longer recognizes that the user is in the application. If the user is still active in the application, the user job will not be ended when the record is deleted.How to display this screen: Enter a valid User ID at the Purge Active Procedures Screen (Selecting the User to Purge).

| Screen Option | Procedure |

|---|---|

|

Delete an active procedure |

Select Delete for the active procedure you want to delete. |

Purge Active Procedures Across Users (MACX)

Purpose: Use this option to display active procedures for all users in your environment and to purge active procedures as necessary if, for example, the job failed to end normally.

JOBCLN: The JOBCLN periodic function deletes each active procedure record for a job that is in END status, or that is not actually active . See Using the JOBCLN Function to Resolve Job Status Across Servers for a discussion.

Deleting an active procedure: Select an active procedure and click Delete to delete it.

Note:

-

You cannot delete an active procedure that is actually running on a server. Only active procedure records that are unrelated to active jobs are eligible for deletion.

-

When you delete an active procedure at this screen, it creates a User Audit record; however, no User Audit record is created if you attempt to delete an active procedure and the deletion does not succeed. See Tracking User, Authority, and Password Updates for more information on the User Audit table.

Purge Active Procedures Screen

How to display this screen: Enter MACX in the Fast path field at the top of any menu, or select Purge Procedures Across Users from a menu.

| Field | Description |

|---|---|

|

User |

The user ID of the person who started the active procedure. For the BILLUSR job, set to the ID of the default user. Alphanumeric, 10 positions; display-only. |

|

Workstation |

If the active procedure is a:

Alphanumeric, 10 positions; display-only. |

|

Job # |

A job number assigned to uniquely identify the active procedure. Numeric, 6 positions; display-only. |

|

Cmp (company) |

The number identifying the company where the active procedure was started. Set to zero for active procedures that are not restricted by company, such as the background jobs; however, set to 999 for certain jobs, including the PICK_OUT process, the BROKER process, and the BROKER_ORD process. See Working with Companies (WCMP) for more information on companies. Numeric, 3 positions; display-only. |

|

Type |

The type of active procedure. Possible types are described below under Active Procedure Types. Filtering based on the Type is supported only for Data Queue and Reorganize. Display-only. |

|

Program |

The name of the program that is active. Note: A program of PFR0100 is displayed for the BILLUPD periodic function runs, although that function uses a Class name rather than a Program name. Alphanumeric, 10 positions; display-only. |

|

Date |

The date when the user started the procedure. Numeric, 6 positions; display-only. |

|

Time |

The time when the user started the procedure. Numeric, 6 positions; display-only. |

Active Procedure Types

Some of the active procedure types displayed at this screen are described below.

| Type | Description | Started When? |

|---|---|---|

|

Data Queue |

data queue |

You create orders through Enter/Maintain Orders (OEOM); maintain purchase orders through Maintaining Purchase Orders (MPOE), receive purchase orders through Receiving Purchase Orders (PORC), and confirm shipments through Manually Confirming Shipments (MCON) |

|

BA |

billing async |

The BILL_ASYNC job starts. See Working with the BILL_ASYNC Job for more information. |

|

BB |

batch billing update |

The SUMVIA periodic function runs. |

|

BC |

batch customer conversion |

You run the batch customer import from Customer Engagement. See Customer Engagement Batch Customer and Sales Integration Process Flow for more information. |

|

BD |

batch deposits |

You submit auto deposits for processing. See Processing Auto Deposits (SDEP) for more information. |

|

BR |

Order Broker orders |

The BROKER_ORD job starts in Working with Integration Layer Processes (IJCT). See Order Broker Integration for background. |

|

BT |

batch tokenization update |

You run a batch tokenization update. See the Data Security and Encryption Guide on My Oracle Support (1988467.1). |

|

CD |

CDC async |

You run the CDC async job. See Working with Drop Ship Background Jobs (WPBJ) for more information. |

|

CL |

credits by LOB |

You submit line of business credits for processing. See Processing Credits by Line of Business (MCLB) for more information. |

|

CR |

catalog request |

You submit the catalog request upload for processing. See Working with the Catalog Request Interface (WCRU) for more information. |

|

CU |

set component upload |

You run the set component upload. See Importing Set Components (WCUP) for more information. |

|

DS |

drop ship processing |

You submit drop ship orders for processing. See Selecting Vendors for Drop Ship Processing (MDSP) for more information. |

|

KU |

PICK_OUT process |

You start the PICK_OUT process in Working with Integration Layer Processes (IJCT). |

|

IO |

INVOICE_OUT process |

You start the INVOICE_OUT process in Working with Integration Layer Processes (IJCT). |

|

LU |

line of business update |

You update statistics for your line of business order queue. See Displaying the Line of Business Order Queue Summary (DLOQ) for more information. |

|

MO |

membership order generation |

You generate membership orders through the Generating Membership Orders (EGMO) menu option. |

|

MS |

mass item substitution |

You select the Processing Item Substitutions (PSUB) menu option. |

|

OA |

online authorization |

See Performing Online Credit Card Authorizations for more information. |

|

OB |

Order Broker |

The BROKER job starts in Working with Integration Layer Processes (IJCT). See Order Broker Integration for background. |

|

PC |

PC manifesting |

Information will be provided at a later date. |

|

PG |

pick slip generation |

You generate pick slips. See Performing Pick Slip Generation for more information. |

|

QZ |

purge security risk periodic function |

You submit the SECRISK Periodic Function. |

|

RE |

REAUTH_JOB |

You submitted the REAUTH job. See Reauthorizing Expired Authorizations for more information. |

|

RI |

retail integration item upload |

You submitted the retail integration item upload. See Working with Retail Integration Item Upload (RIIU) for more information. |

|

RO |

RETURN_OUT process |

You start the RETURN_OUT process in Working with Integration Layer Processes (IJCT). |

|

RZ |

reorganize |

Information will be provided at a later date. |

|

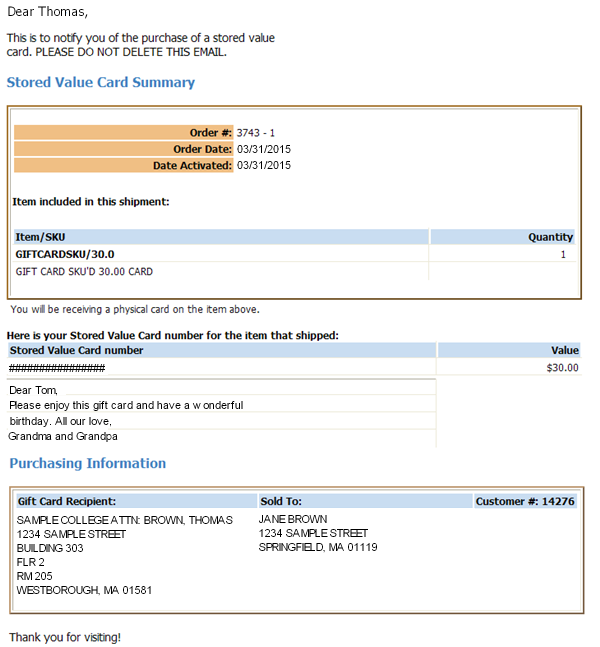

SA |

batch SVC activation |

You submit stored value card activations for processing, if the Use Activation / Reversal Batch Processing (I50) system control value is selected. See Transmitting Activation and Reversal Transactions (SSVC) for more information. |

|

SB |

batch SVC balance inquiry |

The system submits stored value card balance inquiries in batch. See the Perform Balance Inquiry during Batch Authorizations (J19) system control value for more information. |

|

SC |

shipment and return confirmation email generation |

You use the Sending Internet Order Ship Confirmation (ESCF) option or the ECSHCNF periodic function. See Stopping and Restarting Shipment and Return Confirmation Emails for information on how to stop and restart the generation program. |

|

SI |

ship via/item summary inquiry |

You use the Ship Via/Item Inquiry (SVII) menu option. |

|

SP |

SKU purge |

You submit a SKU purge through the Purging SKUs (MPSK) menu option. |

|

SO |

process auto soldouts |

You use the Process Auto Soldouts menu option; see Processing Auto Soldout Cancellations (MASO) for more information. |

|

SR |

batch SVC reversal |

You process deposits that include stored value card reversals if the Perform Authorization Reversal during Deposit Processing (J20) system control value is selected. See Processing Auto Deposits (SDEP) for more information. |

|

SU |

supporting data upload |

You run the supporting data upload. See Importing Item-Related Supporting Data (SDUP) for more information. |

|

TH |

threshold monitor |

You start the THRESHMON background job. See Working with Threshold Values (WTHR) for more information. |

Working with Integration Layer Processes (IJCT)

Purpose: Use this menu option to work with the processes that transmit data between Order Management System and an external system, such as Order Broker.

Note:

The integration layer processes are not restricted by company; when you work with or change a process, it affects all companies.

Configuration: See Advanced Queuing for information on setting up queues.

In this topic:

Also, see the following for more information:

-

Integration Layer Processes and Web Services

-

Integration Layer Processes for a brief listing of integration layer processes and links to more information. Also, see each Process for a link to more information.

-

Troubleshooting XML Messages and Integration Layer Processes

-

Process Overview

As data is processed in Order Management System, the JMS provider sends messages to the integration layer processes for processing. Processes can be one-directional or bi-directional if a response is received (for an outbound process) or generated (for an inbound process).

All messages are processed in the sequence in which they arrive at the queue.

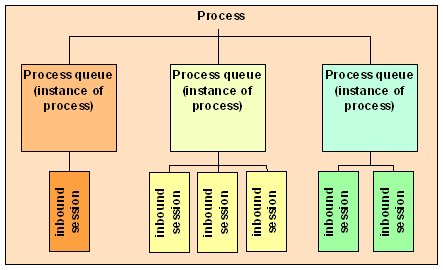

Inbound process structure: Underneath each inbound process at the Work with Integration Layer Process Screen are one or more process queues. Multiple process queues are useful for inbound messages, so that you can receive and process messages from more than one remote system. For example, you might receive inventory transactions from both a warehouse management system and a POS system.

When there are multiple process queues, each queue is an instance of the Inbound program for the process; however, each queue should have a unique Inbound job name so that you can identify and troubleshoot each process separately.

The # inbound sessions for each process queue can be one or more. For example, you might set the number of inbound sessions higher for the process queue that processes orders from your web storefront, to prevent delays; however, you might require only one inbound session for orders you receive from a remote order entry service, because you receive these orders at a scheduled time, and an immediate response is not required.

Inbound process example:

| # | Step |

|---|---|

|

1. |

A remote system sends a message to the Inbound queue specified for an integration layer process queue in Order Management System. |

|

2. |

The process:

|

|

3. |

Optionally, the process sends a response using the Outbound queue specified. |

Generic web service: As an alternative to sending messages directly to the inbound queue specified for each integration layer process queue, you can use the generic web service. In this situation, you send messages to the endpoint for the generic web service, which routes each message to the correct process queue and then routes the generated response. See the Generic Web Services for more information.

For more information see the Web Services Guide on My Oracle Support (ID 2149144.1).

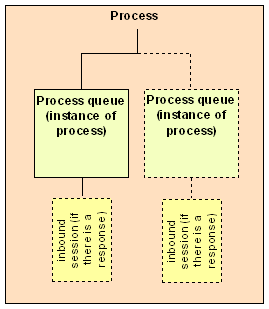

Outbound process structure: Underneath each outbound process at the Work with Integration Layer Process Screen are one or more outbound queues. Multiple outbound queues allow you to send outbound messages to more than one remote system. For example, you might send item information to your POS system and warehouse management system. If you define more than one outbound queue, the system creates a copy of the outbound message for each additional queue whose Enabled field is selected.

An outbound process requires an inbound session only when a response from the remote system is expected.

Outbound process example:

| # | Step |

|---|---|

|

1. |

Activity in Order Management System:

|

|

2. |

The remote system receives the message. |

|

3. |

Optionally, the remote system sends a response using the inbound queue specified. |

Message logging: See Order Management System Application Logs for information on the logs you can use to track XML messages.

XML Versions

Overview: As new elements and attributes are added to existing system-delivered XML messages processed through Integration Layer Job Control, each new version of a message is tagged with a version number. The first version of an XML message is always tagged as version 1.0, but if the next release of Order Management System adds any new attributes or elements to this XML message, this next version of the message is tagged as version 2.0.

Version compatibility: Each new attribute or element is always optional, or implied, so that the integration layer process can always process previous versions of the message.

XML version numbers vs. Order Management System release numbers: The XML version number is independent of the Order Management System release number. For example, version 2.0 of a message might be introduced in Order Management System release 4.0, while version 1.0 of another message might be introduced in Order Management System release 5.5.

About inbound XML messages: Since the integration layer processes can process any previous versions of the related inbound message, the highest version of an inbound XML message supported by an integration layer process is indicated by the Version in field at the Work with Integration Layer Process Screen. For example, if this field is set to 2.0, the integration layer process can process the message in version 1.0 and 2.0.

Not all integration layer processes receive inbound messages. The Version in field is blank for any integration layer processes that are outbound-only.

About outbound XML messages: You use the Select XML Message Version Screen to indicate which version of the outbound message the integration layer process should generate. For example, if version 1.0 and 2.0 are available for an outbound message, you could have the process generate either version. By default, the integration layer process generates version 1.0. Whichever version of the message you select will be sent to all process queues running under the integration layer process.

Outbound XML Version for EMAIL_OUT process: Version 13.0 is the current version of the CWEmailOut message. Earlier versions are not available.

Outbound XML Version for INVOIC_OUT process: Version 7.0 is the current version of the CWInvoiceOut message. Earlier versions are not available.

Outbound XML version for ITEM_OUT process: Version 1.0 of the CWItemOut message includes tags that are not currently supported. The version should be set to 2.0 for the ITEM_OUT process.

Outbound XML Version for ORDER_IN process: Version 12.0 is the current version of the CWOrderOut message. Earlier versions are not available.

Outbound XML version for PICK_OUT process: Versions 1.0 through 4.0 of the CWPickOut message include tags that are not currently supported The version should be set to 5.0 for the PICK_OUT process.

Outbound XML version for VENDOR_OUT process: Versions 1.0 of the CWVendorOut message includes tags that are not currently supported The version should be set to 2.0 for the VENDOR_OUT process.

Outbound XML version for SVC Reversal process: The SVC Reversal process (SVC_REVRSL) uses the outbound XML version defined for the SVC Activation process (SVC_OUT) to generate a stored value card authorization reversal request message. If you define an outbound XML version for the SVC Reversal process, the system ignores this version and continues to use the outbound XML version for the SVC Activation process. Typically, you would want to generate the same outbound message version for both stored value card activations and stored value card authorization reversals.

How does the system identify the current version of a message? The XML Message Version table lists the latest available version of each inbound and outbound XML message. This table is updated each time you apply a new upgrade to Order Management System.

Identifying when new attributes or elements were added to a message: Unless otherwise indicated in the XML layout, each element and attribute was included in version 1.0 of the message. See XML Messages for a listing of inbound and outbound messages processed through Working with Integration Layer Processes (IJCT), including links to the XML layouts.

Versions assigned to system-delivered messages only: Only system-delivered XML messages processed through integration layer processes support this version functionality. For example, e-commerce XML messages and unique XML messages do not support versions. See the Integration Layer Processes for a listing of system-delivered messages processed by the integration layer processes under Working with Integration Layer Processes (IJCT).

Imp guide romcgFor more information see the Web Services Guide on https://support.oracle.com My Oracle Support (ID 2149144.1).

Important:

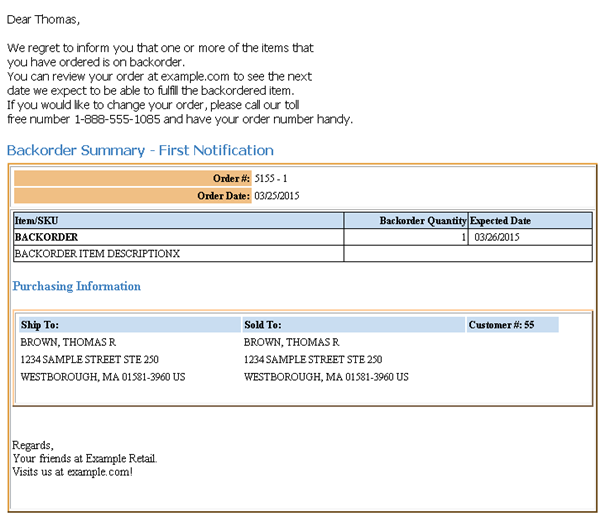

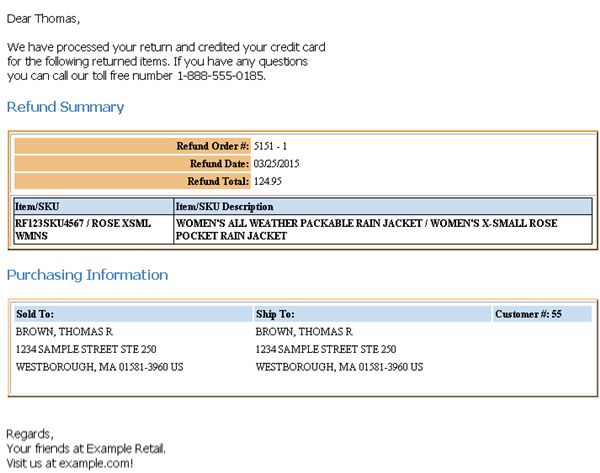

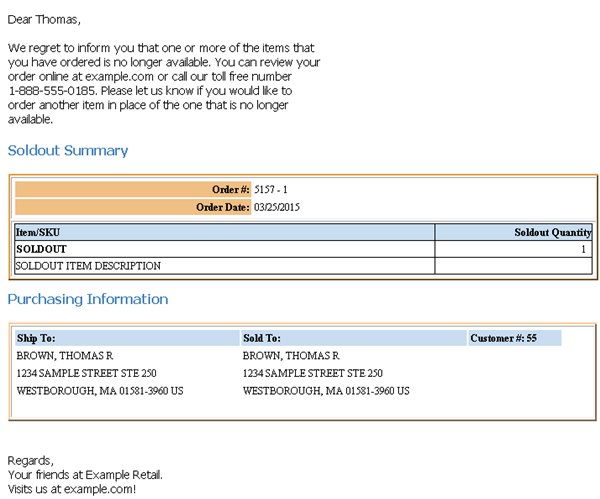

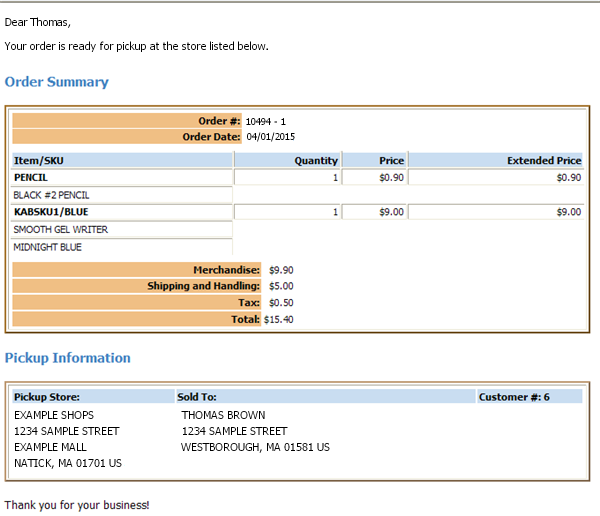

You must select the latest available Outbound version for the EMAIL_OUT process in order for the email generation to work for any notification formats that use information added in versions greater than 1.0 (for example, backorder, soldout, and stored value card notifications). See Outbound Email API for more information.

For more information see the Web Services Guide on My Oracle Support (ID 2149144.1).

Work with Integration Layer Process Screen

Purpose: Use this screen to review and work with integration layer processes.

Hidden processes? If a process is not listed at this screen, it might have had its Type changed to Hide Service. See Hiding an Integration Layer Process for more information.

How to display this screen: Enter IJCT in the Fast path field at the top of a menu or select Integration Layer Job Control from a menu.

| Field | Description |

|---|---|

|

Process |

A code for an integration layer process. Processes include:

For more information see the Web Services Guide on My Oracle Support (ID 2149144.1). Alphanumeric, 10 positions; optional. |

|

Description |

A description of the process. Alphanumeric, 45 positions; optional. |

|

Version in |

The latest version of the inbound XML message that the process is capable of processing. For example, if the Version in is 2.0, this indicates that the process works with version 1.0 or 2.0 of the inbound XML message. See XML Versions for an overview. This field is blank if the process does not process inbound XML messages. Numeric, 3 positions with a 1-place decimal; display-only. |

|

Version out |

The version of the outbound XML message that the process generates. You can select the outbound XML version at the Select XML Message Version Screen. See XML Versions for an overview. This field is blank if the process does not generate outbound XML messages. Numeric, 3 positions with a 1-place decimal; display-only. |

|

Type |

Indicates whether the process uses a JMS provider (advanced queuing) or a web service. Possible types are: MQ = the process uses a JMS provider, advanced queuing, to transmit and receive messages, or uses an Order Management System web service. See Advanced Queuing and Generic Web Services. WS = the process uses an external web service. If you have hidden a process, it is not listed on this screen. See Hiding an Integration Layer Process for more information. |

|

Status |

The status of the queue. Possible statuses are:

See Starting or Ending a Process. Note:

Alphanumeric, 9 positions; display-only. |

|

Active session |

The number of separate sessions that are active for all process queues. You might set up multiple sessions for each process queue of an inbound process to prevent delays in communication. Numeric, 5 positions; display-only. |

|

Start |

The date and time the process, or any of the process queues, was most recently started. The user ID of the person who started the process or any of its queues is also displayed. Date: numeric, 6 positions (in user date format); display-only. Time: numeric, 6 positions (HH:MM:SS format); display-only. User: alphanumeric, 10 positions; display-only. |

|

End |

The date and time the process, or any of the process queues, was most recently ended. The user ID of the person who ended the process or any of its queues is also displayed. Date: numeric, 6 positions (in user date format); display-only. Time: numeric, 6 positions (HH:MM:SS format); display-only. User: alphanumeric, 10 positions; display-only. |

| Screen Option | Procedure |

|---|---|

|

Create an integration layer queue |

Select Create to advance to the Integration Layer Process Screen (Create Mode). |

|

Change the settings for an integration layer process |

Select Change for a process to advance to the Integration Layer Process Screen (Change Mode). |

|

Delete an integration layer process |

Select Delete for a process to delete it. |

|

Review the details of an integration layer process |

Select Display for a process to advance to the Display Integration Layer Process Screen. You cannot change any information at this screen. See the Integration Layer Process Screen (Create Mode) for field descriptions. |

|

Start a process |

Select Start for a process that is in an Inactive status to start all process queues for the process. See Starting or Ending a Process. Note: This option is not available for the CC_TOKEN, MERCH_LOC, EMAIL_OUT, and TAX_INT jobs because they are interactive rather than batch processes. (The SVC_BALANC process also has this status if no companies have the Perform Balance Inquiry during Batch Authorizations (J19) system control value selected.) Also, this option is not necessary for some jobs, such as the ORDER_IN. See Integration Layer Processes for a listing of jobs that indicates whether it is necessary to start or stop the job. To schedule: You can use the STRIJCT periodic function to schedule the start of the integration layer process whose Process ID is defined in the Parameter field for the periodic function. . Troubleshooting: See Using the JOBCLN Function to Troubleshoot IJCT Jobs for information. |

|

End a process |

Select End for a process to end all process queues. See Starting or Ending a Process. Note: This option is not available for the CC_TOKEN, MERCH_LOC, EMAIL_OUT, and TAX_INT jobs because they are interactive rather than batch processes. (The SVC_BALANC process also has this status if no companies have the Perform Balance Inquiry during Batch Authorizations (J19) system control value selected.) Also, this option is not necessary for some jobs, such as the ORDER_IN. See Integration Layer Processes for a listing of jobs that indicates whether it is necessary to start or stop the job. To schedule: You can use the ENDIJCT End IJCT Process Passed periodic function to schedule the end of the integration layer process whose Process ID is defined in the Parameter field for the periodic function. Troubleshooting: See Using the JOBCLN Function to Troubleshoot IJCT Jobs for information. |

|

Work with the queues for a process |

Select Work with Queues for a process to advance to the Work with Integration Layer Process Queues Screen, where you can start, end, or work with individual process queues. Only processes whose Type is MQ use queues. |

|

Define trigger rules for an outbound process |

Select Trigger Rules for a process to advance to the Outbound Interface Trigger Rules Screen or the Select Trigger Rules File Window. This option is not available for processes that do not use trigger rules. |

|

Define XML inclusion rules for an outbound process |

Select XML Inclusion for a process to advance to the Outbound Interface XML Inclusion Screen. This option is available only for processes that use XML inclusion. |

|

Select the XML version to use for outbound messages |

Select Outbound XML Ver for a process to advance to the Select XML Message Version Screen. This option is not available for processes that do not generate outbound messages. Also, inclusion rules are not implemented for the MERCH_LOC process, which uses Order Broker’s Locate Items messages. See Merchandise Locator API for an overview. |

|

Work with background jobs |

Select Background Jobs to advance to the Work with Background Jobs Screen. |

|

Work with Drop Ship background jobs |

Select Drop Ship Jobs to advance to the Work with Drop Ship Background Jobs Screen. |

Integration Layer Process Screen (Create Mode)

Purpose: Use this screen to create an integration layer process. For example, you might create a new process similar to a system-delivered process in order to communicate with multiple authorization services.

How to display this screen: Select Create at the Work with Integration Layer Process Screen.

| Field | Description |

|---|---|

|

Process ID |

A code for the job that performs integration layer updates between Order Management System and an external system. See Work with Integration Layer Process Screen for a description of each. Alphanumeric, 10 positions; required. |

|

Description (unlabeled field next to Process ID) |

A description of the subsystem job that is used when the integration layer process is active. Alphanumeric, 45 positions; required. |

|

Status |

The current status of the integration layer job. Possible statuses are:

Note:

Alphanumeric, 9 positions; display-only. |

|

Communication type |

Indicates whether the process uses a JMS provider (advanced queuing) or a web service. Possible types are: Message Queue (default) = the process uses a JMS provider, advanced queuing, to transmit and receive messages, or the job uses an Order Management System web service. See Advanced Queuing and Generic Web Services. Web Service = the process uses a web service that is external to Order Management System. Hide Service = this process is not used and will be hidden from the Work with Integration Layer Process Screen once you accept your entries on this screen. See Hiding an Integration Layer Process for more information. Required. |

|

Inbound Processing: |

|

|

Inbound program |

For an inbound process, the name of the job that receives and interprets the XML message from an external system to Order Management System, and performs any additional processing in Order Management System. Alphanumeric, 10 positions; optional. |

|

Active session(s) |

The total number of active sessions from the Work with Integration Layer Process Queues Screen. Set to zero on the Create screen. Numeric, 3 positions; display-only. |

|

Inbound XML Msg/WSDL Doc Name |

Note: The only integration layer process that requires you to specify the name of a WSDL file in this field is the TAX_INT process. Other processes that use web services do not require you to specify a WSDL. Alphanumeric, 50 positions; optional. |

|

Outbound Processing: |

|

|

Outbound job name |

For an outbound process, the name of the job that generates the outbound XML message. Alphanumeric, 10 positions; optional. |

|

Outbound program |

For an outbound process, the name of the program that the job uses to build the XML message and send it to an external system. Alphanumeric, 10 positions; optional. |

|

Outbound delay time |

For an outbound process, this is the number of seconds to wait before checking the IL Outbound Trigger table for triggers in a ready (R) status. For outbound processes requiring additional configuration options, the system also uses the outbound delay time to determine the length of time to wait before performing a delete transaction, giving the system time to generate a delete download message. Note: For outbound processes that require additional configuration options, you must enter an outbound delay time. Numeric, 5 positions; optional. |

|

Outbound XML message |

The outbound message for the integration layer process to generate. Alphanumeric, 50 positions; optional. |

Integration Layer Process Screen (Change Mode)

To change: Select Change for an integration layer process at the Work with Integration Layer Process Screen to advance to the Integration Layer Process screen in Change mode. See the Integration Layer Process Screen (Create Mode) for field descriptions.

Starting or Ending a Process

Overview: You can start or stop the Integration Layer processes at the Work with Integration Layer Process Screen by selecting Start or End, if the process is not currently active.

When you select to start a process, the system first confirms that the process is not currently running on any server. If not, the system changes its status from Inactive to Starting to Active.

When you select to end a process, the system first confirms that the process is currently running on any server. If is currently running, the system changes its status from Active to Ending to Inactive. There may be a delay while the process completes processing all records that existed when the process began.

Note:

If you end a process while it is in the “resting period” defined in the Outbound Delay Time, the process does not check to see if it should be ending until the Outbound Delay Time is over. So if, for example, the Outbound Delay Time is 15 minutes and the resting period just started, then the process does not end for almost 15 minutes.

Ending an individual process queue: If you end an individual process queue for a process and another process queue is still active, the system updates the status of the integration layer process to Ending. The process will remain in an Ending status until you end the other active process queue(s) for the integration layer process.

For information on how to start or end individual process queues for a process, see the Work with Integration Layer Process Queues Screen.

Note:

If you have more than one enabled integration layer process queue, the system may update the Active session field for the integration layer process to 1, even though more than one session actually went active on the Job Management Screen and Work with Integration Layer Process Queues Screen. In this situation, stop the integration layer process again and restart it so that the number of Active sessions matches the number of sessions that have actually started.

Interactive processes: This option is not available for the CUSTOMER_IN, CUST_HIST, CUST_SRCH, CUSTOMER_IN, EMAIL_OUT, INV_INQUIRY, MERCH_LOC, ORDER_IN, RETURN_IN, TAX_INT, and WORKFLOW jobs because they are interactive rather than batch processes. The SVC_BALANC process also has this status if no companies have the Perform Balance Inquiry during Batch Authorizations (J19) system control value selected. Also, this option is not necessary for some jobs, such as the ORDER_IN. See Integration Layer Processes for a listing of jobs that indicates whether it is necessary to start or stop the job.

Scheduling when an integration layer process starts and stops: You can schedule a periodic function to start or stop an integration layer process at a particular time. See Scheduling Jobs and Additional Interface (INT) Periodic Functions for more information on how to schedule a periodic function and for a list of the periodic functions used to start and stop the integration layer jobs.

Hiding an Integration Layer Process

Purpose: You can hide an unused integration layer process in order to simplify the information displayed at the Work with Integration Layer Process Screen.

Which processes are eligible to be hidden? You can hide a process only if:

-

its current status is Inactive or Interactive

-

it does not have any process queues set up through the Work with Integration Layer Process Queues Screen, or all existing process queues have the Enabled flag unselected

Before you hide a process: You should confirm that it is not a process that you are currently using or will need to use in the near future. For example, if you hide:

-

TAX_INT: You will not be able to use the integration with Vertex or AvaTax.

-

Outbound processes (such as ITEM_OUT, PO_OUT): Messages will not generated.

-

Inbound processes (such as INVTRAN_IN): Messages will not be received and processed. In the case of an interactive process, no response message will be generated.

-

EMAIL_OUT: You will not be able to send the CWEmailOut message for any template whose XML only? flag is selected; however, the system will continue to generate email notifications for email templates whose XML only? flag is not selected. See Working with E-Mail Notification Templates (WEMT) for more information.

Note:

If you have already configured the merchandise locator integration with Order Broker, this integration will continue to work after you hide the MERCH_LOC process.

Also, you should confirm that you do not have one of the Interface (INT) Periodic Functions to Start and Stop IJCT Jobs set up for a process that you are going to hide. If you do, the periodic function might start the process, even though it is hidden.

How to hide a process: At the Integration Layer Process Screen (Change Mode), change the Communication type to Hide Service.

How to show a hidden process: Once a process is hidden, you cannot show it again through an option at a screen in Order Management System. Instead, Oracle staff will need to query the Integration Layer Process table (MSILPR) and reset the ILP Communication type field from H to MQ (if the type was previously Message Queue) or WS (if the type was previously Web Service).

Note:

The JOBCLN periodic function does not update a job in H (hidden) status.

The BROKER, BROKER_ORD, MERCH_LOC, and TAX_INT processes use the Web Service type; the other processes use the Message Queue type.

Work with Integration Layer Process Queues Screen

Purpose: Use this screen to work with the process queues that run for each process displayed at the Work with Integration Layer Process Screen. Inbound processes might have multiple process queues if you receive messages from multiple remote systems; similarly, outbound processes might have multiple process queues if you broadcast messages to multiple remote systems. See Process Overview for more information on how processes relate to process queues.

It is not necessary to set up queues for a process that uses an external web service (Type at the Work with Integration Layer Process Queues Screen = WS).

Note:

You cannot create multiple process queues for the CUSTOMER_IN, CUST_HIST, CUST_SRCH, CUSTOMER_IN, EMAIL_OUT, INV_INQUIRY, MERCH_LOC, ORDER_IN, RETURN_IN, TAX_INT, and WORKFLOW processes. If you create multiple process queues for any of these processes, the system will only process messages for the queue with a sequence number of 1.

How to display this screen: Select Work with Queues for a process at the Work with Integration Layer Process Screen.

| Field | Description |

|---|---|

|

Process ID |

The process you selected at the Work with Integration Layer Process Screen. The description is to the right. Alphanumeric, 10 positions; display-only. |

|

Sequence |

A unique sequence number to identify a queue for a process. You cannot create multiple process queues for the CC_TOKEN, SVC_OUT, SVC_BALANC, SVC_REVRSL, MERCH_LOC, or EMAIL_OUT processes. If you create multiple process queues for any of these processes, the system only processes messages for the queue with a sequence number of 1. Numeric, 3 positions; optional. |

|

Description |

The description of the process queue. Alphanumeric, 30 positions; optional. |

|

Active sessions |

The number of inbound sessions that are currently active for each process queue. You might have more than one active session for a process queue to prevent delays in responses; for example, you might have multiple active sessions for the process queue that receives new orders from your web storefront. Note: Active sessions do not apply to outbound processing. Numeric, 5 positions; display-only. |

|

Start |

The date and time the process queue was most recently started. The user ID of the person who started the process queue is also displayed. Note: This field is not displayed for outbound queues. Date: numeric, 6 positions (in user date format); display-only. Time: numeric, 6 positions (HH:MM:SS format); display-only. User: alphanumeric, 10 positions; display-only. |

|

End |

The date and time the process queue was most recently ended. The user ID of the person who ended the process queue is also displayed. Note: This field is not displayed for outbound queues. Date: numeric, 6 positions (in user date format); display-only. Time: numeric, 6 positions (HH:MM:SS format); display-only. User: alphanumeric, 10 positions; display-only. |

| Option | Procedure |

|---|---|

|

Create a new process queue |

Select Create to create a new queue for the selected process. You advance to the Integration Layer Process Queue Screen in Create mode. Note: You cannot create multiple process queues for the CC Token Process, SVC Activation, SVC Balance Inquiry, SVC Reversal, MERCH_LOC, or EMAIL_OUT processes. |

|

Change a process queue |

Select Change for a process queue to work with it. You advance to the Integration Layer Process Queue Screen in Change mode. |

|

Delete a process queue |

Select Delete for a process queue to delete it. |

|

Display a process queue |

Select Display for a process queue to advance to the Integration Layer Process Queue Screen in Display mode; all fields will be display-only. |

|

Start a process queue |

Select Start for a process queue to start it. If none of the other process queues were currently active, the status of the process at the Work with Integration Layer Process Screen changes to Active. The Start date, time, and user indicated for the process are also updated. Note:

|

|

End a process queue |

Select End for a process queue to end it. If none of the other process queues were currently active, the status of the process at the Work with Integration Layer Process Screen changes to Inactive. The End date, time, and user indicated for the process are also updated. |

|

View status of a batch of messages in a queue |

Select View batch status for a process queue to advance to the Work with Integration Process Control Screen. |

|

Start all process queues for the process |

Select Start all to start all process queues for the selected process. The status of the process at the Work with Integration Layer Process Screen changes to Active. The Start date, time, and user indicated for the process are also updated. Note:

|

|

End all process queues for the process |

Select End all to end all process queues for the selected process. The status of the process at the Work with Integration Layer Process Screen changes to Inactive. The End date, time, and user indicated for the process are also updated. |

Starting or Stopping Process Queues

You can start or stop processes in two ways:

-

All existing process queues for a process:

-

At the Work with Integration Layer Process Screen: see Starting or Ending a Process.

-

At the Work with Integration Layer Process Queues Screen: see below.

-

-

Individual process queues for a process: At the Work with Integration Layer Process Queues Screen:

-

Starting a process queue: Select Start for a process queue to start it. If none of the other process queues were currently active, the status of the process at the Work with Integration Layer Process Screen changes to Active. The Start date, time, and user indicated for the process are also updated. Note: The Enabled flag for the process queue must be selected for you to be able to start it.

-

Ending a process queue: Select End for a process queue to end it. If none of the other process queues were currently active, the status of the process at the Work with Integration Layer Process Screen changes to Inactive. If one of the other process queues is currently active, the status of the process at the Work with Integration Layer Process Screen changes to Ending; the process will remain in an Ending status until you end the other active process queue(s) for the integration layer process.The End date, time, and user indicated for the process are also updated.

-

Note:

The BROKER_ORD job checks on whether it needs to end or to continue processing each time it has processed requests for all eligible companies and the Outbound Delay Time has passed.

Interactive processes: Starting and stopping a process queue is not available for the CUSTOMER_IN, CUST_HIST, CUST_SRCH, CUSTOMER_IN, EMAIL_OUT, INV_INQUIRY, MERCH_LOC, ORDER_IN, RETURN_IN, TAX_INT, and WORKFLOW jobs because they are interactive rather than batch processes. Also, this option is not necessary for some jobs, such as the ORDER_IN. See Integration Layer Processes for a listing of jobs that indicates whether it is necessary to start or stop the job.

System started: The system automatically starts a process queue for the SVC Activation, and SVC Reversal processes if a message is requested or received and the process is not currently running.

Starting or stopping all process queues for a process at the Work with Integration Layer Process Queues Screen:

-

Starting all process queues for a process: Select Start all to start all process queues for the selected process. The status of the process at the Work with Integration Layer Process Screen changes to Active. The Start date, time, and user indicated for the process are also updated. Note: Only process queues whose Enabled flag is selected will start.

-

Ending all process queues for a process: Select End all to end all process queues for the selected process. The status of the process at the Work with Integration Layer Process Screen changes to Inactive. The End date, time, and user indicated for the process are also updated.

Interactive processes: Starting and stopping a process queue is not available for the CUSTOMER_IN, CUST_HIST, CUST_SRCH, CUSTOMER_IN, EMAIL_OUT, INV_INQUIRY, MERCH_LOC, ORDER_IN, RETURN_IN, TAX_INT, and WORKFLOW jobs because they are interactive rather than batch processes. The SVC_BALANC process is also interactive if no companies have the Perform Balance Inquiry during Batch Authorizations (J19) system control value selected. Also, this option is not necessary for some jobs, such as the ORDER_IN. See Integration Layer Processes for a listing of jobs that indicates whether it is necessary to start or stop the job.

Which job queue? The integration layer jobs run automatically in the QSYSNOMAX job queue in order to avoid slowing down any other jobs that might be running in other job queues on the system.

Integration Layer Process Queue Screen

Purpose: Use this screen to create, change, or display a process queue for an integration layer process.

How to display this screen: At the Work with Integration Layer Process Queues Screen:

-

Select Create to advance to this screen in Create mode.

Note:

You cannot create multiple process queues for the SVC_OUT, SVC_BALANC, SVC_REVRSL, MERCH_LOC, or EMAIL_OUT processes.

-

Select Change for a process queue to advance to this screen in Change mode.

-

Select Display for a process queue to advance to this screen in Display mode. All fields will be display-only.

| Field | Description |

|---|---|

|

Process ID |

The Process ID for the selected process. The description of the process is to the right. Process ID: alphanumeric, 10 positions; display-only. Process description: alphanumeric, 45 positions; display-only. |

|

Description |

The description of the process queue to run for the integration layer process. For example, for an inbound process, you might use this field to indicate the source of the messages. Alphanumeric, 30 positions; required. |

|

Enabled |

Indicates whether the process queue can process messages. Valid values are:

Note: If this field is unselected for all process queues, you will not be able to start the process. For outbound processing, the system sends the outbound message to queues only if their Enabled field is selected. |

|

# inbound sessions |

The number of sessions to run under this process queue. You might run multiple sessions for process queues that require an immediate response, such as the process queue that receives new order messages from the web storefront. Multiple sessions are used only for inbound process queues; outbound processes should have this field set to 1 for their process queues. Note: If you leave this field blank, you will not be able to start the process queue. If this field is blank for all process queues for a process, you will not be able to start the process. Numeric, 5 positions; required. |

|

Wait time |

The number of seconds Order Management System waits for a response from an external system. Used only for two-way interfaces (outbound/inbound). If the message waits on the target queue longer than this number of seconds the message is automatically deleted. Numeric, 6 positions; optional. |

|

Inbound Processing: |

|

|

Active session (s) |

Indicates the number of sessions that are currently active for this process queue. Included in Change or Display mode only. Numeric, 5 positions; display-only. |

|

Inbound queue manager |

This field is currently implemented. Alphanumeric, 48 positions; optional. |

|

Inbound queue |

The queue in the queuing database where this process queue reads messages originating from the remote server or system. Required for inbound process queues. Alphanumeric, 48 positions; optional. |

|

Inbound XML message |

The name of the inbound XML message; informational only. Alphanumeric, 50 positions; optional. |

|

Inbound job name |

The name of the job that interprets the XML message from the external system to Order Management System. This is the Job Name listed on the Job Management screen, available through the My Jobs option. If there are multiple process queues for a process, each instance of the job should have a unique name. Required for inbound process queues. Alphanumeric, 10 positions; optional. |

|

Outbound Processing: |

|

|

Outbound queue manager |

This field is not currently implemented. Alphanumeric, 48 positions; optional. |

|

Outbound queue |

The queue to which this process queue sends messages for transmission to the remote server. Required for outbound process queues. Alphanumeric, 48 positions; optional. |

|

Outbound XML message |

The name of the outbound XML message; informational only. Alphanumeric, 50 positions; optional. |

Creating a Process Queue

Note:

You cannot create multiple process queues for the SVC_OUT, SVC_BALANC, SVC_REVRSL, MERCH_LOC, or EMAIL_OUT processes.

-

At the Work with Integration Layer Process Queues Screen, select Create to advance to this screen in Create mode.

-

Complete the Description and set the Enabled flag, and then any additional fields required for the process queue. Select OK to accept your entries.

Work with Integration Process Control Screen

Purpose: Use this screen to review the status of a batch of messages. This screen is useful if you need to troubleshoot the location of a batch message.

Each batch status represents a record in the Integration Process Control table. The system creates a record in the Integration Process Control table when the system sends or receives a batch of messages via an integration layer process.

Purging integration process control records: When one of the integration layer jobs listed above becomes active (from a user manually starting the job, through a periodic function, or through the job starting automatically), the system submits the ILPURGE job to determine if any of the records in the Integration Process Control table should be purged. If the integration process control record has an ILC date stamp that is over 7 days old, the system removes the record from the Integration Process Control table.

Purpose: Select View batch status for a process queue at the Work with Integration Layer Process Queues Screen.

Batch status records on this screen sort in descending date and time sequence.

| Field | Description |

|---|---|

|

Process |

The name and description of the batch integration layer process whose integration process control records you are reviewing. Code: alphanumeric, 10 positions; display-only. Description: alphanumeric, 45 positions; display-only. |

|

Queue Name |

A unique sequence number to identify a queue for a process, and the description of the process queue. Queue: numeric, 3 positions; display-only. Description: alphanumeric, 30 positions; display-only. |

|

Job |

The job name for the process associated with the integration process control record. For example, PICK_GEN indicates a integration process control record created for the Batch CC Authorization integration layer process; these records represent a batch of credit card authorizations sent to the authorization service. Alphanumeric, 10 positions; optional. |

|

Status |

The status of the integration process control record. Normal transmissions process through the following statuses: TRF, SNT, RCV, RIN, CMP. TRF Unknown status indicates the batch message is unknown and has not been transmitted. SNT Sent indicates the batch message transmission has been sent to the external system. RCV Received (IDC Server) indicates the batch message transmission has been received from the external system and all background processing for the batch is complete. A batch may remain in a received status if the associated job, such as pick slip generation, has timed out or moved on before the batch could be updated to Complete. No further action is required for a batch that remains in a Received status. RIN Receiving indicates the batch message transmission is in the process of being received. CMP Complete indicates the batch message has been completed. FLD Error (Sending) indicates the batch message transmission has failed. Note:

Status code: Alphanumeric, 3 positions; optional. Status description: Alphanumeric, 24 positions; display-only. |

|

Date |

The date the batch message transmission was sent to or received from an external system. Numeric, 6 positions (in user date format); display-only. |

|

Time |

The time the batch message transmission was sent to or received from an external system. Numeric, 6 positions (HH/MM/SS format); display-only. |

|

Reference ID |

The next available number from the Batch Auth File Trace Number number assignment value. Numeric, 16 positions; display-only. |

| Screen Option | Procedure |

|---|---|

|

Delete an integration process control record |

Select Delete for an integration process control record to delete it. |

|

Review an integration process control record |

Select Display for an integration process control record to advance to the Display Integration Process Control Screen. |

|

Change the status of an integration process control record that is not yet complete |

Select Change status for an integration process control record to advance to the Change Status window. You cannot change the status of an integration process control record that is in CMP complete status. |

Display Integration Process Control Screen

Purpose: Use this screen to review the details of an integration process control record. This screen is useful if you need to troubleshoot the location of a batch message.

How to display this screen: Select Display for an integration process control record at the Work with Integration Process Control Screen.

| Field | Description |

|---|---|

|

Process |

The name and description of the batch integration layer process whose integration process control records you are reviewing. Code: alphanumeric, 10 positions; display-only. Description: alphanumeric, 45 positions; display-only. |

|

Queue |

A unique sequence number to identify a queue for a process, and the description of the process queue. Queue: numeric, 3 positions; display-only. Description: alphanumeric, 30 positions; display-only. |

|

Job # |

The job number for the process associated with the integration process control record; this is the process that sent the batch message. Alphanumeric, 6 positions; display-only. |

|

Job name |

The job name for the process associated with the integration process control record. For example, PICK_GEN indicates an integration process control record created for the Batch CC Authorization integration layer process; these records represent a batch of credit card authorizations sent to the authorization service. Alphanumeric, 10 positions; display-only. |

|

User |

The user ID of the person who submitted the process associated with the batch messages. Alphanumeric, 10 positions; display-only. |

|

Status |

The status of the integration process control record. Normal transmissions process through the following statuses: TRF, SNT, RCV, RIN, CMP. TRF Unknown status indicates the batch message is unknown and has not been transmitted. SNT Sent indicates the batch message transmission has been sent to the external system. RCV Received (IDC Server) indicates the batch message transmission has been received from the external system and all background processing for the batch is complete. A batch may remain in a received status if the associated job, such as pick slip generation, has timed out or moved on before the batch could be updated to Complete. No further action is required for a batch that remains in a Received status. RIN Receiving indicates the batch message transmission is in the process of being received. CMP Complete indicates the batch message has been completed. FLD Error (Sending) indicates the batch message transmission has failed. Note: If the integration process control record is in a sent or error status, the system will continue to wait for a response for that record. You must resolve any errors before receiving the next transaction. Status code: Alphanumeric, 3 positions; optional. Status description: Alphanumeric, 24 positions; display-only. |

|

Date |

The date the batch message transmission was sent to or received from the external system. Numeric, 6 positions (in user date format); display-only. |

|

Time |

The time the batch message transmission was sent to or received from the external system. Numeric, 6 positions (HH/MM/SS format); display-only. |

|

Reference ID |

The next available number from the Batch Auth File Trace Number number assignment value. Numeric, 16 positions; display-only. |

|

Comment |

Informational error message regarding the batch message transmission, indicating a transmission error has occurred. Alphanumeric, 60 positions; display-only. |

Change Status Window (Integration Process Control)

Purpose: Use this window to change the status of an integration process control record. You might change the status of a record if you experienced communication problems and need to re-send or receive transactions.

You cannot change an integration process control record that is already in a CMP Complete status: Status Already Complete.

How to display this window: Select Change status for an integration layer process control record at the Work with Integration Layer Process Queues Screen.

To change: Select a status and click OK to update the integration process control record to that status.

-

Complete indicates the batch message has been completed.

-

Failed indicates the batch message transmission has failed.

-

Ready indicates the batch message is ready for transmission.

-

Received indicates the batch message transmission has been received from the external system.

-

Sent indicates the batch message transmission has been sent to the external system.

-

Transferred indicates the batch message has been transmitted.

Defining Outbound Interface Trigger Rules

Outbound interface trigger rules are the criteria a transaction must meet in order for the system to create an IL outbound trigger. For each outbound process, you can create trigger rules for certain tables. For example, you can create trigger rules for the Item table and SKU table to control the Item Outbound job. If you enter more than one criterion, the record must meet all of the criteria in order to generate a trigger.

Example: For the ITEM_OUT process, you can specify to create item download triggers for SKUed items in company 555 that are located in warehouse 20. To do this, for the Item table trigger rules, select a Test of Equal and enter 555 as the Value for the Company trigger field, and select a Test of Equal and enter ’Y’ as the Value for the Allow SKU’s trigger field. For the SKU table trigger rules, select a Test of Equal and enter 20 as the Value for the Warehouse trigger field.

| Item table criteria | SKU table criteria | Results |

|---|---|---|

|

The Company field must equal 27 or 555. The Allow SKUs field must equal ’Y’. |

The Warehouse field must equal 20. |

The system generates a SKU trigger only if the item/SKU being created, updated, or deleted is in company 27 or company 555 and the item is SKU’d and the SKU is located in warehouse 20. If the item/SKU does not meet all of the criteria, no trigger is created. |

You can create trigger rules for the following outbound processes.

| For IL Process job: | you can create trigger rules for: | Example: |

|---|---|---|

|

CUST_OUT |

Company, Customer class, Inactive?, and Country fields |

You can specify to create Customer Download messages only for active customers in the US and Canada. To do this:

|

|

ITEM_OUT |

Item (INITEM) SKU (INSKU) |

You can specify to only create item download triggers for company 555, items that are SKU’ed and whose SKUs are located in warehouse 20. To do this:

See Item Outbound Trigger Rules. |

|

INVOIC_ OUT |

Invoice Header (OEINHD) Order Header (OEORDR) |

You can specify to only create invoice download triggers for debit invoices and not credit invoices. To do this, select a Test of Equal and enter I as the Value for the Invoice type trigger field. |

|

INV_ DOWNLD |

Item (INITEM) Item Warehouse (INIWRE) SKU (INSKU) Warehouse (INWRHS Item UPC (ITMUPC) |

You can specify to exclude drop ship items, non-inventory items, and membership items. To do this, select a Test of Equal and enter Y as the Value for the Drop ship item, Non-inventory, and Membership trigger fields. |

|

PICK_OUT |

Pick Control Header (FLPCTH) |

You can specify by company only. |

|

PO_OUT |

Purchase Order Header (POH) |

You can specify to only create purchase order download triggers for purchase orders that are created, closed, cancelled in company 12 and vendor 10001. To do this, select a Test of In and enter 12 as the Value for the Company trigger field and select a Test of Equal and enter 10001 as the Value for the Vendor trigger field. |

|

RETURN_OUT |

Order Header (OEORDR) |

You can specify to only create return authorization download triggers for return authorizations that are created, changed or deleted in company 7 or 555 and are associated with orders whose order type is W. To do this, select a Test of In and enter 7 555 as the Value for the Company trigger field, and select a Test of Equal and enter W as the Value for the Order Type trigger field. |

|

VENDOR_ OUT |

Vendor (POVEND) |

You can specify to create vendor download triggers only for companies 27 and 555 and vendor 202. To do this, select a Test of In and enter 27 555 as the Value for the Company trigger field, and select a Test of Equal and enter 202 as the Value for the Vendor # trigger field. |

Note:

Applying trigger rules for the BROKER job is not currently implemented.

Defining Trigger Rule Values

To create a trigger rule, select the fields in the table that should control trigger creation. For each trigger field, define:

-

a Test value: indicates how the system compares the record against the trigger rule criteria.

-

a Value: defines the trigger rule criterion.

Example: For the Company trigger field, select a Test of Equal and enter 555 as the Value field. This indicates the system creates IL outbound triggers only for company 555.

Field type: The T (type) field indicates if the value you enter must be numeric or alphanumeric.

-

N = the Value must be numeric.

-

A = The Value is alphanumeric.

Note:

-

Enter alphanumeric values between single quotes: for example, ’Y’.

-

When entering a list or range of alphanumeric values, separate each value with a space: for example, ’S F V’.

-

When entering a list or range of numeric values, separate each value with a comma: for example, 2,5,7.

-

If you select a Test value for a field you must also enter a Value, and vice versa.

-

The system does not validate that the value you enter for a trigger field is valid (if the field requires valid values) or is within the maximum field positions (for example, the Company field is 3 positions). Refer to your Database Listing to review field attributes for a table.

-

Fields that are in the table but are not included in the XML message are not included as a trigger field.

| Test value | Description |

|---|---|

|

blank |

A trigger rule is not specified for the field. |

|

Between (falls within a defined range) |

The field must fall within the trigger rule value range. For example, the Ship via must fall within 1 and 5. |

|

Equal |

The field must equal the trigger rule value. For example, the Company field must equal 555. |

|

Greater than |

The field must be greater than the trigger rule value. For example, the Cost field must be greater than 5.00. |

|

Greater than or equal |

The field must be greater than or equal to the trigger rule value. For example, the Cost field must be greater than or equal to 5.00. |

|

In (equal to a listed value) |

The field must match a trigger rule value. For example, the Company field must match 27, 409, or 555. |

|

Less than |

The field must be less than the trigger rule value. For example, the Cost field must be less than 500.00. |

|

Less than or equal |

The field must be less than or equal to the trigger rule value. For example, the Cost field must be less than or equal to 500.00. |

|

Not Between |

The field must not fall within the trigger rule value range. For example, the Postal code must not be between 96700 and 96899. |

|

Not Equal |

The field must not be equal to the trigger rule value. For example, the Company field must not be 25. |

|

Not In (not equal to a listed value) |

The field must not match a trigger rule value. For example, the Company field must not be 25 or 444. |

Select Trigger Rules File Window

Purpose: This window opens if you can define trigger rules for more than one table. If a process has only one table available for trigger rules, you advance directly to the Outbound Interface Trigger Rules Screen for this process.

How to display this window: Select Trigger Rules for an outbound process for which you can create trigger rules for more than one table.

| Field | Description |

|---|---|

|

Process |

The code and name of the process for which you are creating trigger rules. Alphanumeric, 10 positions; display-only. |

|

File name |

The table for which you are creating trigger rules. Select a table to advance to the Outbound Interface Trigger Rules Screen. Alphanumeric, 10 positions; optional. |

Outbound Interface Trigger Rules Screen

Purpose: Use this screen to define trigger rules for an outbound job.

The appearance of this screen varies based on the outbound process for which you are defining outbound trigger rules.

Using this screen: See Defining Outbound Interface Trigger Rules for a discussion.

How to display this screen:

-

Select Trigger Rules for an outbound process at the Work with Integration Layer Process Screen.

-

Select a table at the Select Trigger Rules File Window.

| Field | Description |

|---|---|

|

Process ID |

The code and name of the outbound process for which you are creating trigger rules. Alphanumeric, 10 positions; display-only. |

|

File name |

The table for which you are creating trigger rules. Alphanumeric, 10 positions; display-only. |

|

Field |

The field in the table for which you can create a trigger rule. When evaluating a record to determine whether to create an IL outbound trigger, the system compares the record’s field value against the trigger rule for the field. Alphanumeric, 15 positions; display-only. |

|

Test |

Indicates how the system compares the record against the trigger rule criteria. blank = A trigger rule is not specified for the field. Between (falls within a defined range) = The field must fall within the trigger rule value range. For example, the Ship via must fall within 1 and 5. Equal = The field must equal the trigger rule value. For example, the Company field must equal 555. Greater than = The field must be greater than the trigger rule value. For example, the Cost field must be greater than 5.00. Greater than or equal = The field must be greater than or equal to the trigger rule value. For example, the Cost field must be greater than or equal to 5.00. In (equal to a listed value) = The field must match a trigger rule value. For example, the Company field must match 27, 409, or 555. Less than = The field must be less than the trigger rule value. For example, the Cost field must be less than 500.00. Less than or equal = The field must be less than or equal to the trigger rule value. For example, the Cost field must be less than or equal to 500.00. Not Between = The field must not fall within the trigger rule value range. For example, the Postal code must not be between 96700 and 96899. Not Equal = The field must not be equal to the trigger rule value. For example, the Company field must not be 25. Not In (not equal to a listed value) = The field must not match a trigger rule value. For example, the Company field must not be 25 or 444. Alphanumeric, 5 positions; optional. |

|

Value |

Defines the trigger rule criterion. The system compares the trigger field value against the value of this field in each record.

When entering alphanumeric values, you must enter the value between single quotes; for example ’Y’. When entering a list or range of values, separate each value with a space; for example, 27 555 or ’S F V’. If you define a Value here, you must also select a Test value. Alphanumeric, 50 positions; optional. |

|

Type |

Indicates if the value you enter is numeric or alphanumeric. N = numeric A = alphanumeric Note: Enter alphanumeric values between single quotes; for example ’Y’. Alphanumeric, 1 position; display-only. |

Outbound Interface XML Inclusion Screen

XML inclusion defines which elements to include in a download message.

-

If the element is included, that element and its parents are included in the generated download XML message.

-

If the element is excluded, that element and its children are excluded from the generated download message.

Remember: Parent elements are those elements that nest other elements; any elements nested underneath the parent element are its children.

Example: Some of the elements in the generic item download message are displayed below. In this example: Item is the parent of ItemInformation and ItemInformationDetail. ItemInformation is the parent of ItemInformationDetail and the child of Item. ItemInformationDetail is the child of ItemInformation and Item.

Item

SKU

UPC

Warehouse

ItemWarehouse

-

If you include the Item element, you can still exclude the SKU element. If you exclude the Item element, the SKU element and its children (UPC, Warehouse, and ItemWarehouse) are also excluded.

-

If you include the UPC element, the system automatically includes the SKU element. You can still exclude the Warehouse element.

-

If you exclude the Item element, the process still generates an “empty” message with just the top element information. For example, if you exclude the entire message for the INV_DOWNLD process, the resulting “empty” message would resemble:

<Message source="OROMS" target="cwi" type="CWInventoryDownload" date="02112006" time="10:38:10">

</Message>

This screen appears different based on the outbound process for which you are defining XML inclusion rules.

Important:

After you change XML inclusion rules, they do not take effect until after you restart the application.

You can define XML inclusion rules for the following outbound processes:

| For IL Process job: | You can create XML inclusion rules for: |

|---|---|

|

CUST_OUT |

parent and child elements included in the Customer Download XML Message (CWCustomerDownload). See Customer Outbound XML Inclusion For more information see the Web Services Guide on My Oracle Support (ID 2149144.1). |

|

ITEM_OUT |