| Skip Navigation Links | |

| Exit Print View | |

|

Sun Datacenter InfiniBand Switch 648 Topic Set |

Documentation, Support, and Training

Understanding Administrative Commands

Monitoring the InfiniBand Fabric

Controlling the InfiniBand Fabric

Understanding Signal Routing Through the Switch

Understanding Switch Startup and Component Addition

Understanding ILOM on the Switch

Switching Between the ILOM Shell and the Linux Shell

Controlling ILOM Targets (CLI)

Upgrading the Switch Firmware Through ILOM (CLI)

Administering ILOM (Web Interface)

Access ILOM From the Web Interface

Monitoring ILOM Targets (Web Interface)

Controlling ILOM Targets (Web Interface)

Upgrading the Switch Firmware Through ILOM (Web Interface)

Understanding InfiniBand Cabling

Understanding Switch Specifications

Understanding the Installation

Fabric Card and Line Card Fillers

Suggested Tools for Installation

Antistatic Precautions for Installation

Installing the InfiniBand Software Stack

Install the HPC Software Suite

Remove the Shipping Carton Contents

Unsecure the Chassis From the Pallet

Install the Rail Assemblies in the Rack

Install the Chassis in the Rack

Inspecting the Midplane Condition

Midplane Fabric Card Connector Nomenclature

Inspect the Pins on the Rear Side of the Midplane

Midplane Line Card Connector Nomenclature

Inspect the Pins on the Front Side of the Midplane

Inspecting the Fabric Cards Condition

Fabric Card Handling Guidelines

Inspect the Fabric Card Chassis Condition

Inspect the Fabric Card Retainer Bolts Condition

Inspect the Fabric Card XBOW Connectors Condition

Inspecting the Line Cards Condition

Inspect the Line Card Chassis Condition

Inspect the Line Card Retainer Bolts Condition

Inspect the Line Card XBOW Connectors Condition

Inspect the Line Card CXP Connectors Condition

Inspecting the InfiniBand Cables Condition

Inspect the InfiniBand Cables Hardware Condition

Inspect the InfiniBand Cables Connector Condition

Install the Midplane Stiffener

Install the Fabric Cards or Fabric Card Fillers

Access the CMC From the Serial Management Port

Set the Initial UBoot Parameters

Access the CMC From the Network Management Port

Display the CMC FRU ID Information

Verify the Power Supply Status

Display the Power Supply FRU ID Information

Create the guid.txt File for Installation

Display the Fabric Card FRU ID Information

Display the Line Card FRU ID Information

Attach Cables to the CXP Connectors

Display the InfiniBand Cable FRU ID Information

Verifying the InfiniBand Fabric

Discover the InfiniBand Fabric Topology

Perform Diagnostics on the InfiniBand Fabric

Validate the InfiniBand Fabric and Report Errors

Understanding Service Procedures

Servicing the Fabric Cards and Fabric Card Fillers

Servicing the InfiniBand Cables

Doing Supportive Software Tasks

Understanding Switch-Specific Commands

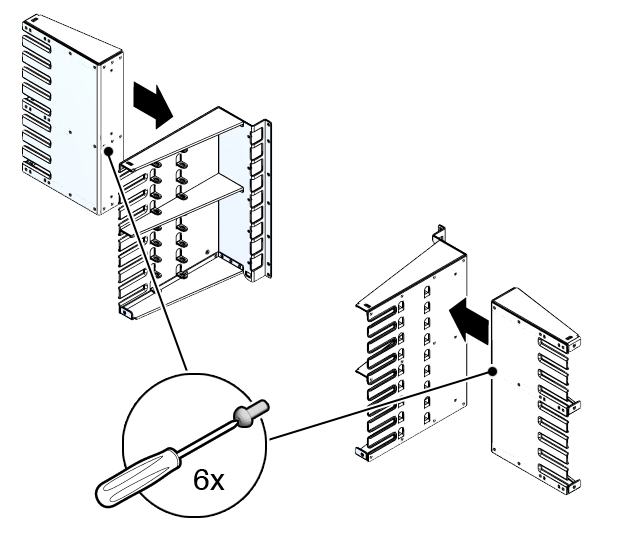

The cable trees have two parts, a main trunk and an outer branch. These pieces are left-right symmetrical and their orientation for installation can be determined as follows:

The main trunk installs at the front of the rack with the reinforcing ribs and cable shelf tabs toward the centerline of the rack. The square EMI screen mounting hole is at the bottom of the main trunk.

The outer branch installs onto the main trunk with the reinforcing ribs facing to the rear of the rack. The center reinforcing rib has 4 openings above and 5 openings below.

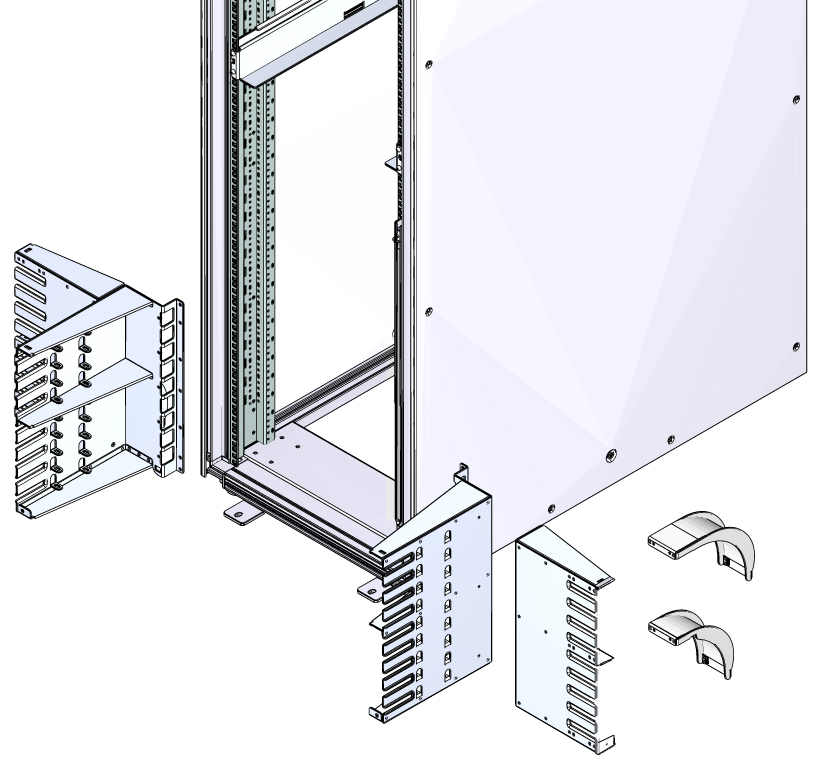

Note - For this procedure, the term cabinet holes refers to the holes in the posts of the cabinet. For the Sun Rack II cabinet, these holes are square. The holes are numbered from 1 starting at the very bottom. Hole 2, 3, 4, and so on, are the second, third, fourth, and so on, hole from the bottom. The numbering scheme printed on the posts is not used.

Note - This task requires two people.

See the table in Installation Sequence.

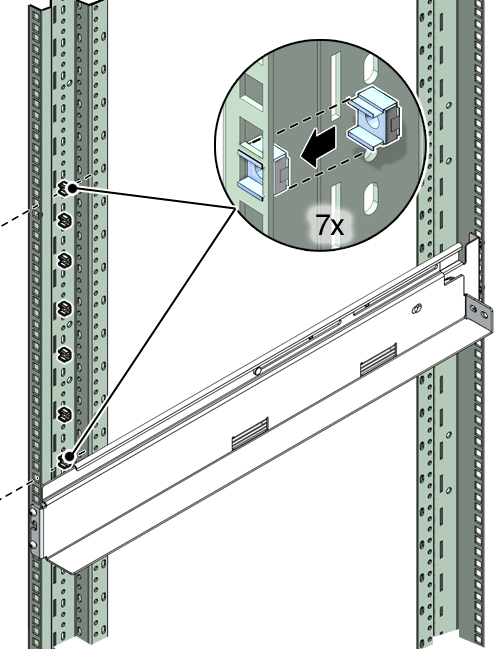

Finger tighten the screw only.

where a, b, c, d, e, f, and g are the respective cabinet holes:

6, 8, 13, 19, 24, 30, and 33 for bottom mounting

40, 42, 47, 53, 58, 64, and 67 for middle mounting

74, 76, 81, 87, 92, 98, and 101 for top mounting

Note - When in the correct position, the cable tree can rest upon the front flange of the slide rail.

Have a helper assist in aligning the cable tree mounting screw holes with the captive nuts in the rack.