Electrical Power Guidelines

The modular system uses AC power.

Note - The maximum power of a modular system is dependent on the number of nodes, the configuration of the compute node, and the workload. The maximum power of a modular system can be up to the rating of the PDU selected, given some worst-case scenario workloads. Use the power calculator to get an approximate value on the power for a given configuration. For up-to-date information about the power consumption, go to Oracle's Sun Power Calculators at http://www.oracle.com/us/products/servers-storage/sun-power-calculators/index.html and click Netra Modular System.

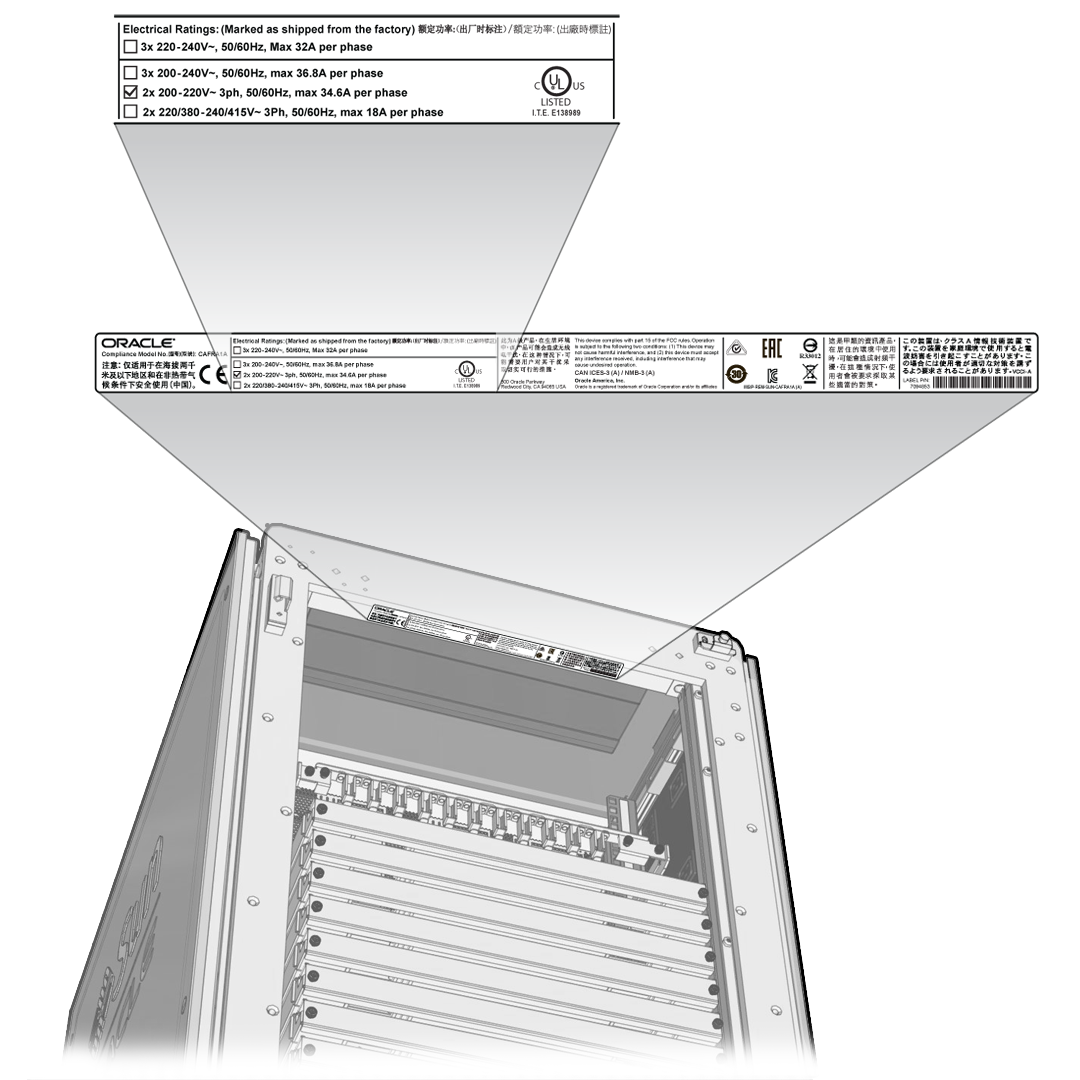

The Compliance label applied to the top rear cross-frame member of the modular system displays the electrical rating for the modular system. You must open the back door to view this label. The label shows a tick mark next to the rating for the modular system.

The modular system can operate effectively over a range of voltages and frequencies. However, the modular system must have a reliable power source. The modular system can be damaged if the ranges are exceeded. Electrical disturbances such as the following might damage the modular system:

-

Fluctuations caused by brownouts

-

Wide and rapid variations in input voltage levels or in input power frequency

-

Electrical storms

-

Faults in the distribution system, such as defective wiring

To protect the modular system from such disturbances, use a dedicated power distribution system, power-conditioning equipment, lightning arresters, or power cords to protect from electrical storms.

| Caution - The intra-building ports on the coupler panel and ports on the copper switches of the equipment or subassembly is suitable for connection to intra-building or unexposed wiring or cabling only. The intra-building ports of the equipment or subassembly MUST NOT be metallically connected to interfaces that connect to the OSP or its wiring. These interfaces are designed for use as intra-building interfaces only (type 2 or type 4 ports as described in GR-1089) and require isolation from the exposed OSP cabling. The addition of primary protectors is not sufficient protection to connect these interfaces metallically to OSP wiring. |